Toyota Sienna Service Manual: Air Conditioning Compressor Magnetic Clutch Circuit

DESCRIPTION

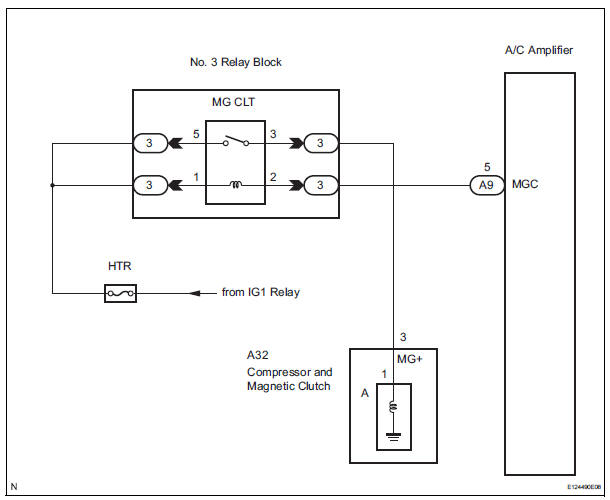

When the A/C amplifier is turned on, a magnetic clutch ON signal is sent from the MGC terminal of the A/ C amplifier. Then, the MG CLT relay turns on to operate the magnetic clutch.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK CAN COMMUNICATION SYSTEM

(a) Use the intelligent tester to check if the CAN communication system is functioning normally.

Result

2 CHECK MULTIPLEX COMMUNICATION SYSTEM

(a) Use the intelligent tester to check if the multiplex communication system is functioning normally.

Result

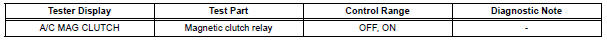

3 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the ACTIVE TEST and then check that the relay operates.

ACTIVE TEST / AIR CONDITIONER:

OK: Magnetic clutch relay operates.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

4 INSPECT FUSE (HTR)

(a) Remove the HTR fuse from the driver side junction block.

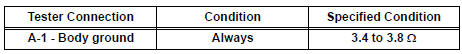

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Reconnect the HTR fuse to the driver side junction block.

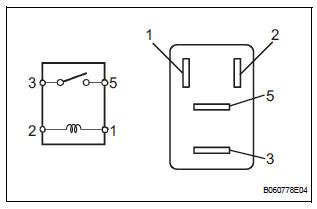

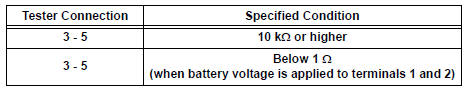

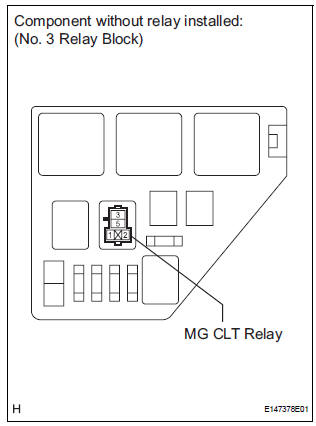

5 INSPECT RELAY (MG CLT)

(a) Remove the MG CLT relay from the No. 3 relay block.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Install the MG CLT relay to the No. 3 relay block.

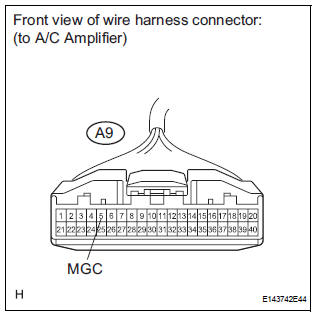

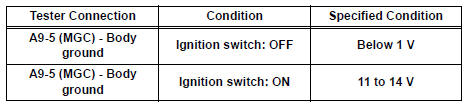

6 CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - BATTERY)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the voltage according to the value(s) in the table below.

Standard voltage

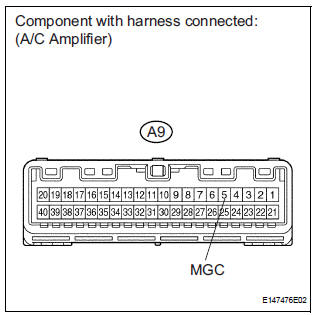

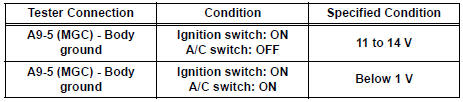

7 INSPECT A/C AMPLIFIER

(a) Reconnect the connector to the A/C amplifier.

(b) Measure the voltage according to the value(s) in the table below.

Standard voltage

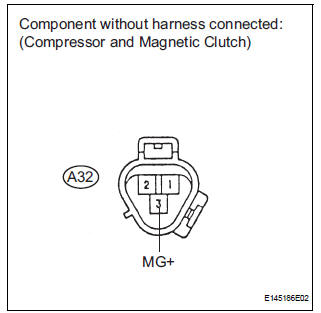

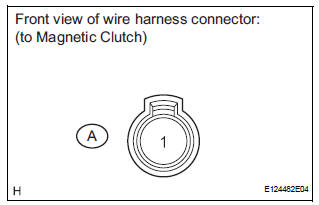

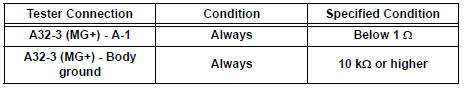

8 INSPECT COMPRESSOR AND MAGNETIC CLUTCH

(a) Disconnect the connector from the compressor and magnetic clutch.

(b) Disconnect the connector from the magnetic clutch.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

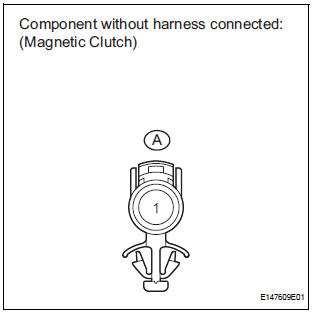

9 INSPECT MAGNETIC CLUTCH

(a) Measure the resistance according to the value(s) in the table below.

Standard resistance

(b) When connector terminal A1 is connected to the positive (+) battery terminal, check that the following occurs: 1) the magnetic clutch's operating sound can be heard, and 2) the magnetic clutch's hub and rotor lock.

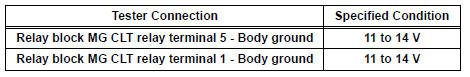

10 CHECK HARNESS AND CONNECTOR (NO. 3 RELAY BLOCK - BATTERY)

(a) Remove the MG CLT relay from the No. 3 relay block.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the table below.

Standard voltage

REPAIR OR REPLACE HARNESS OR CONNECTOR

Blower Motor Circuit

Blower Motor Circuit

DESCRIPTION

The blower motor is operated by signals from the A/C amplifier. Blower motor

speed signals are

transmitted by changes in the Duty Ratio.

Duty Ratio

The duty ratio is the ratio of ...

Rear Air Conditioning Control Panel Circuit

Rear Air Conditioning Control Panel Circuit

DESCRIPTION

This is the rear A/C system control signal circuit as well as the power

supply circuit of the rear A/C control

assembly.

Pulse signals regarding rear A/C control panel switch operat ...

Other materials:

Tire Pressure Warning Reset Switch Circuit

DESCRIPTION

The ECU enters the initialization mode and performs initialization

automatically, when the tire pressure

warning ECU receives the signal from the tire pressure warning reset switch. If

the ECU receives the

signal, the tire pressure warning light blinks 3 times (1 second on, 1 seco ...

Inspection

1. INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY OPERATION

(a) Apply the parking brake and turn the ignition switch

to the ON position.

(b) Depress the brake pedal and check that the engine

starts only when the shift lever is in the N or P

position and the engine does not start when the shift ...

Disassembly

1. INSPECT UNDERDRIVE PACK CLEARANCE

HINT:

(See page AX-262)

2. REMOVE UNDERDRIVE CLUTCH FLANGE NO.2 HOLE

SNAP RING

a) Using a screwdriver, remove the underdrive clutch

flange No.2 snap ring.

3. REMOVE UNDERDRIVE CLUTCH DISC NO.1

(a) Remove the flange, 4 discs and 4 plates from the

...