Toyota Sienna Service Manual: Clearance Warning ECU Power Source Circuit

DESCRIPTION

This circuit provides power to the clearance warning ECU.

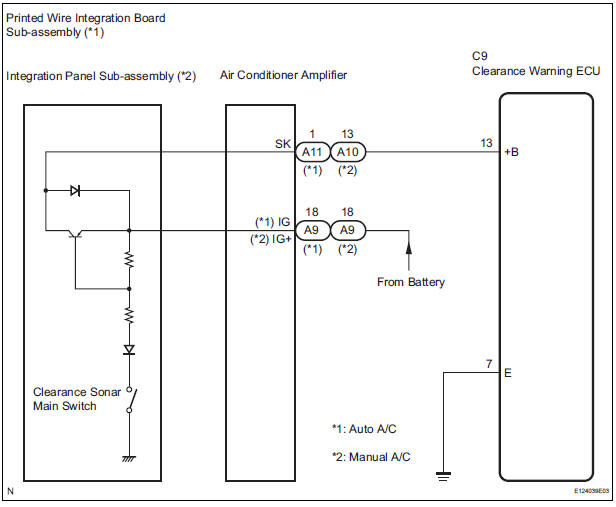

WIRING DIAGRAM

INSPECTION PROCEDURE

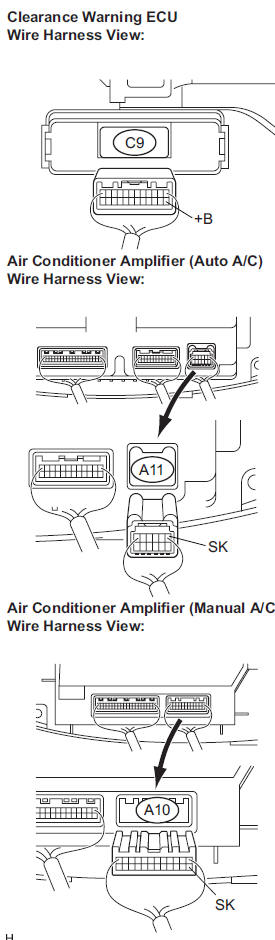

1 CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU - AIR CONDITIONER AMPLIFIER)

- Disconnect the connectors from the clearance warning ECU C9 and air conditioner amplifier connector A10 or A11.

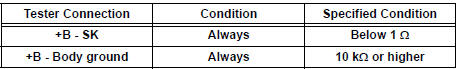

- Measure the resistance according to the value(s) in the table below.

Standard resistance

2 CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU - BODY GROUND)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

3 INSPECT CLEARANCE WARNING ECU

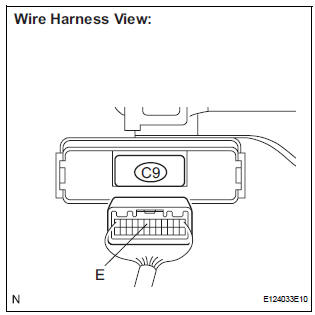

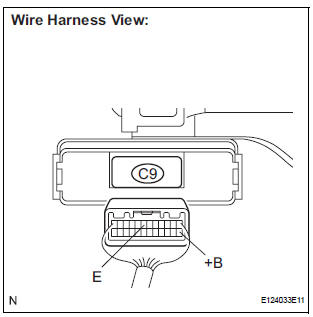

- Disconnect the clearance warning ECU connector.

- Turn the ignition switch ON.

- Turn the clearance sonar main switch ON.

- Measure the voltage between terminals +B and E of the ECU.

Standard voltage: 10 to 14 V

Result

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

4 INSPECT PRINTED WIRE INTEGRATION BOARD SUB-ASSEMBLY

- Check that the malfunction disappears when a known good printed wire integration board sub-assembly is installed.

OK: Malfunction disappears

REPLACE PRINTED WIRE INTEGRATION BOARD SUB-ASSEMBLY

5 INSPECT INTEGRATION PANEL SUB-ASSEMBLY

- Check that the malfunction disappears when a known good integration panel sub-assembly is installed.

OK: Malfunction disappears.

REPLACE INTEGRATION PANEL SUB-ASSEMBLY

No. 1 Clearance Warning Buzzer Circuit

No. 1 Clearance Warning Buzzer Circuit

DESCRIPTION

The clearance warning ECU receives the ultrasonic sensor signal to sound the

front warning buzzer.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT FRONT BUZZER

Remove the c ...

No. 2 Clearance Warning Buzzer Circuit

No. 2 Clearance Warning Buzzer Circuit

DESCRIPTION

The clearance warning ECU receives the ultrasonic sensor signal to sound the

rear warning buzzer.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK HARNESS AND CONNECTOR (CLEARANCE WAR ...

Other materials:

Typical tire symbols

Run-flat tire or full-size tire

Compact spare tire

Tire size

DOT and Tire Identification Number (TIN)

Uniform tire quality grading

For details, see “Uniform Tire Quality Grading” that follows.

Location of treadwear indicators

Run-flat tire (RFT) or standard ti ...

Adjustment procedure

Manual seat

Seat position adjustment lever

Seatback angle adjustment lever

Vertical height adjustment lever (driver’s side only)

Lumbar support adjustment switch (driver’s side only)*

*: If equipped

Power seat

Seat position adjustment switch

Seatback angle a ...

Mass or Volume Air Flow Circuit Range / Performance

Problem

DTC P0101 Mass or Volume Air Flow Circuit Range / Performance

Problem

DESCRIPTION

Refer to DTC P0100

DTC No.

DTC Detection Condition

Trouble Area

P0101

High voltage:

Conditions (a), (b) and (c) continue for more than

10 seconds (2 trip de ...