Toyota Sienna Service Manual: Data list / active test

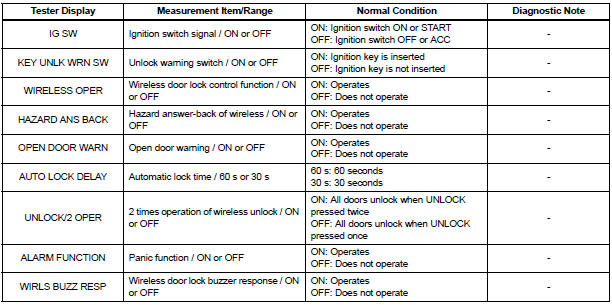

1. DATA LIST

- The wireless door lock control data list can be

displayed while the intelligent tester is connected to

the DLC3 with the ignition switch in the ON position.

Follow the prompts on the tester screen to access the DATA LIST.

BODY:

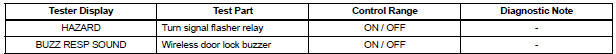

2. ACTIVE TEST

HINT: Performing the ACTIVE TEST using the intelligent tester allows components such as the relay, VSV and actuator to operate without removing parts. Performing the ACTIVE TEST as the first step in troubleshooting is one way to shorten labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- According to the display on the tester, preform the ACTIVE TEST.

HINT: The ignition switch must be turned to the ON position to proceed with the ACTIVE TEST using the intelligent tester.

BODY:

DTC check / clear

DTC check / clear

1. DTC CHECK/CLEAR (USING INTELLIGENT TESTER:)

DTC check

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position.

Read the DTCs on t ...

Diagnostic trouble code chart

Diagnostic trouble code chart

HINT:

If a trouble code is displayed during the DTC check,

inspect the circuit listed for that code. For details of the

code, refer to the "See page" in the DTC chart.

...

Other materials:

Removal

1. REMOVE INSTRUMENT CLUSTER NO.1 FINISH PANEL CENTER

2. REMOVE INSTRUMENT CLUSTER NO.2 FINISH

PANEL CENTER

3. REMOVE INSTRUMENT CLUSTER FINISH PANEL GARNISH

4. REMOVE NAVIGATION RECEIVER ASSEMBLY WITH BRACKET

Remove the 4 screws.

Disconnect the connector and remove the

n ...

Brake

GENERAL MAINTENANCE

1. INSPECT BRAKE LINE PIPES AND HOSES

HINT:

Check the entire circumference and length of the brake

hoses using a mirror as required in a well-lighted area.

Turn the front wheels fully right or left before checking

the front brakes.

(a) Check all the brake lines and h ...

Removal

1. REMOVE FRONT DOOR WINDOW FRAME MOULDING

Remove the screw.

Using a heat light, heat the front door window frame

moulding between 40 to 60 C (104 to 140 F).

NOTICE:

Do not heat the front door window frame

moulding excessively.

Slide the front door window frame moulding upward

...