Toyota Sienna Service Manual: Differential system

PRECAUTION

NOTICE:

When disconnecting the negative (-) battery terminal, initialize the following systems after the terminal is reconnected.

1. Before disassembly, clean the outside of the rear differential assembly and remove any sand or mud to prevent it from entering the inside of the assembly during disassembly and reassembly.

2. When removing a connected part made of light alloy such as a rear differential carrier cover, tap it off with a plastic hammer. Do not attempt to pry it off with a screwdriver.

3. Always arrange disassembled parts in order and protect them from dust.

4. Before reassembly, thoroughly clean and dry each part or then apply hypoid gear oil LSD to it. Do not use alkaline cleaner for aluminum or rubber parts and ring gear set bolts. Also, do not clean rubber parts such as O-rings or oil seals with non residue solvent.

5. Coat any sliding surface and rotating part with hypoid gear oil LSD.

6. When holding a component part in a vise, be sure to place an aluminum sheet under the part. Do not put it directly on the vise.

7. Be careful not to damage the contact surfaces of the case. Such damage may cause oil leakage.

8. Before applying sealant, remove deposited oil sealant and clean the part to be sealed using non residue solvent.

9. Do not apply oil immediately after installing sealed parts. Leave it for at least an hour.

10.Damage on the surface of an oil seal, O-ring or gasket may cause oil leakage.

11.When press-fitting an oil seal, be careful not to damage the oil seal lip and outside periphery.

12.When replacing a bearing, replace the inner and outer races as a set.

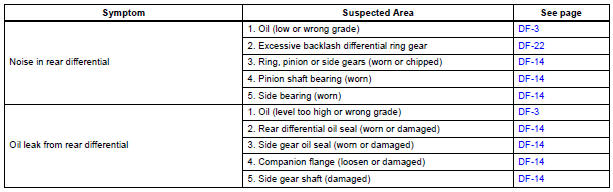

PROBLEM SYMPTOMS TABLE

HINT: Use the table below to help you find the cause of the problem.

The numbers indicate the priority of the likely cause of the problem. Check each part in order. If necessary, replace these parts.

DIFFERENTIAL SYSTEM:

Differential

Differential

...

Differential oil

Differential oil

Adjustment

1. INSPECT DIFFERENTIAL OIL

(a) Stop the vehicle on the level place.

(b) Remove the differential filler plug and gasket.

(c) Check that the oil surface is within 5 mm (0.20 in.) ...

Other materials:

Parking Brake Switch Circuit

DESCRIPTION

The Multiplex network body ECU receives parking brake switch signal.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 READ VALUE OF INTELLIGENT TESTER

Connect the intelligent tester to DLC3.

Turn the ignition switch ON and push the intelligent

tester main switch ON.

Se ...

Door Courtesy Switch Circuit

DESCRIPTION

The Multiplex network body ECU detects the condition of the door courtesy

switch assembly.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 READ VALUE OF INTELLIGENT TESTER

Connect the intelligent tester to DLC3.

Turn the ignition switch to ON and push the intelligent

tester ...

Open in Front Pretensioner Squib LH Circuit

DTC B0136/74 Open in Front Pretensioner Squib LH Circuit

DESCRIPTION

The front pretensioner squib LH circuit consists of the center airbag sensor

assembly and the front seat

outer belt assembly LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0136/74 i ...