Toyota Sienna Service Manual: Disassembly

1. Remove repair service starter kit

(a) Remove the nut and disconnect the lead wire from the repair service starter kit.

(b) Remove the 2 screws which are used to secure the repair service starter kit to the repair service starter kit.

(c) Remove the repair service starter kit.

(d) Remove the return spring and the plunger from the repair service starter kit.

2. REMOVE STARTER YOKE ASSEMBLY

(a) Remove the 2 through bolts and pull out the starter yoke together with the starter commutator end frame.

(b) Remove the starter yoke from the starter commutator end frame.

3. REMOVE STARTER ARMATURE PLATE

(a) Remove the starter armature plate from the starter yoke.

4. REMOVE DRIVE HOUSING STARTER BEARING COVER

(a) Using a screwdriver, remove the drive housing starter bearing cover.

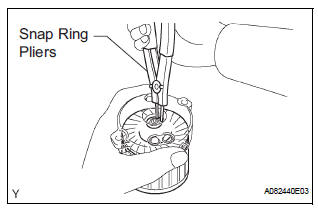

5. REMOVE STARTER ARMATURE ASSEMBLY

(a) Using snap ring pliers, remove the snap ring and plate washer.

(b) Remove the starter armature from the commutator end frame.

6. REMOVE PLANETARY GEAR

(a) Remove the 3 planetary gears from the repair service starter kit.

Removal

Removal

1. REMOVE BATTERY (See page EM-26)

2. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

3. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page FU-13)

4. REMOVE AIR CLEANER FILTER ELEMENT (See page

EM-2 ...

Inspection

Inspection

1. Inspect starter assembly

NOTICE:

These tests must be performed within 3 to 5 seconds

to avoid burning out the coil.

(a) Perform the pull-in test.

(1) Disconnect the lead ...

Other materials:

Inspection

1. INSPECT VENTILATION VALVE

(a) Install a clean hose to the ventilation valve.

(b) Check the ventilation valve operation.

(1) Blow air into the cylinder head side, and check

that air passes through easily.

NOTICE:

Do not suck air through the valve.

Petroleum substances i ...

Short in Side Squib LH Circuit

DTC B0115/47 Short in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0115/47 is recorded when a short ci ...

Problem symptoms table

HINT:

Use the table below to help determine the cause of the

problem symptom. The likely causes of the problem are

indicated in descending order. Check each suspected area

in order. Repair or replace faulty parts or perform

adjustments as necessary.

Inspect the fuse and rel ...