Toyota Sienna Service Manual: Evaporative Emission System

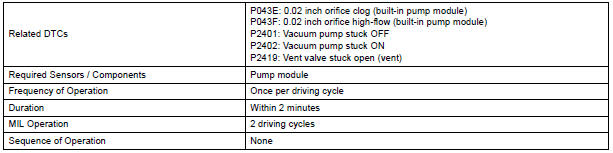

DTC P043E Evaporative Emission System Reference Orifice Clog Up

DTC P043F Evaporative Emission System Reference Orifice High Flow

DTC P2401 Evaporative Emission System Leak Detection Pump Control Circuit Low

DTC P2402 Evaporative Emission System Leak Detection Pump Control Circuit High

DTC P2419 Evaporative Emission System Switching Valve Control Circuit Low

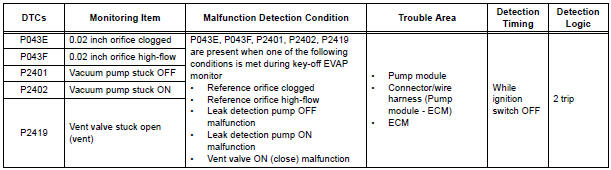

DTC SUMMARY

HINT: The 0.02 inch orifice is located inside the pump module.

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System.

INSPECTION PROCEDURE

Refer to the EVAP System.

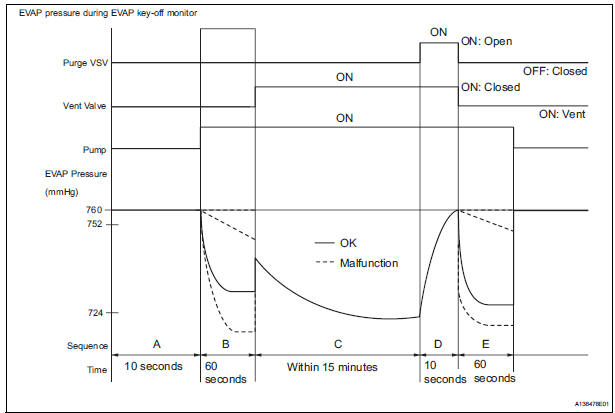

MONITOR DESCRIPTION

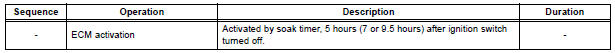

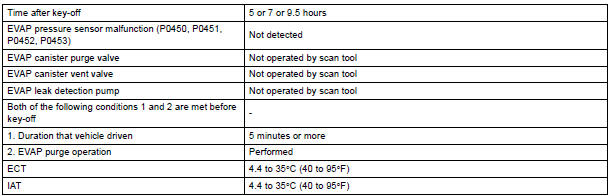

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT: *1: If the engine coolant temperature is not below 35C (95F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35C (95F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

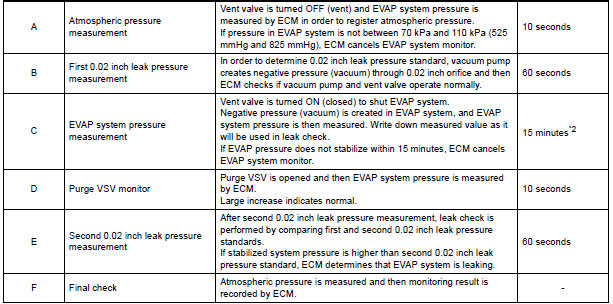

*2: If there is only a small amount of fuel in the fuel tank, stabilizing the EVAP pressure takes longer than usual.

The leak detection pump creates negative pressure through the reference orifice. When the system is normal, the EVAP pressure is in 724 to 752 mmHg* and saturated within a minute.

If not, the ECM interprets this as a malfunction. The ECM will illuminate the MIL and set DTC if this malfunction is detected in consecutive drive cycle.

*: Typical valve

MONITOR STRATEGY

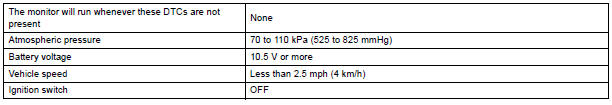

TYPICAL ENABLING CONDITIONS

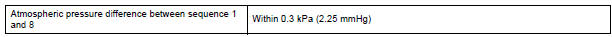

Key-off monitor sequence 1 to 8

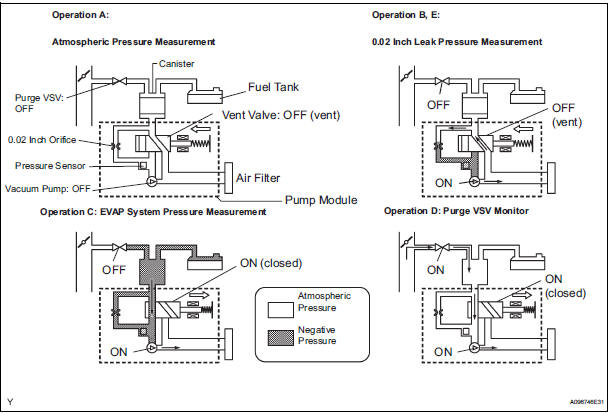

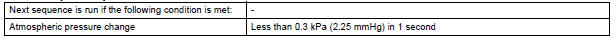

1. Atmospheric pressure measurement

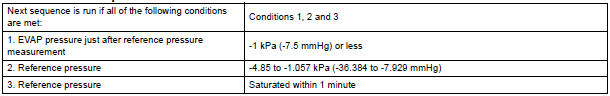

2. First reference pressure measurement

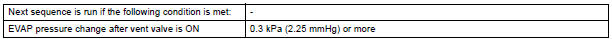

3. EVAP canister vent valve close stuck check

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

7. Leak check

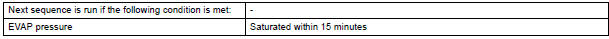

8. Atmospheric pressure measurement

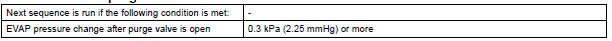

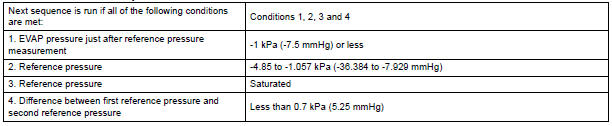

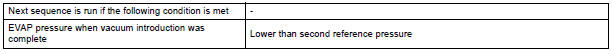

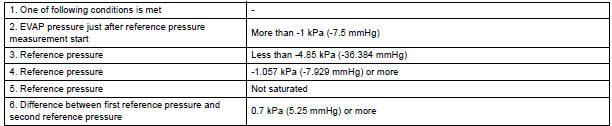

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS

Catalyst System Efficiency Below Threshold

Catalyst System Efficiency Below Threshold

DTC P0420 Catalyst System Efficiency Below Threshold

(Bank 1)

DTC P0430 Catalyst System Efficiency Below Threshold

(Bank 2)

MONITOR DESCRIPTION

The ECM uses the sensors mounted in front of and be ...

Evaporative Emission Control System Incorrect

Purge Flow

Evaporative Emission Control System Incorrect

Purge Flow

DTC P0441 Evaporative Emission Control System Incorrect

Purge Flow

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission)

System.

INSPECTION PROCEDU ...

Other materials:

Disposal

1. DISPOSE OF FRONT SEAT OUTER BELT ASSEMBLY (WHEN INSTALLED IN VEHICLE)

NOTICE:

Never dispose of a front seat outer belt assembly

with an deactivated pretensioner.

The seat belt pretensioner produces an exploding

sound when it activates, so perform the operation

outdoors wh ...

U151f automatic transaxle

Service data

TORQUE SPECIFICATIONS

...

How to proceed with

troubleshooting

HINT:

Use these procedures to troubleshoot the power door lock

control system.

The intelligent tester should be used in steps 3 and 5.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

Interview the customer to confirm the trouble

3 INSPECT COMMUNICATION FUNCTI ...