Toyota Sienna Service Manual: Evaporative Emission System Reference Orifice

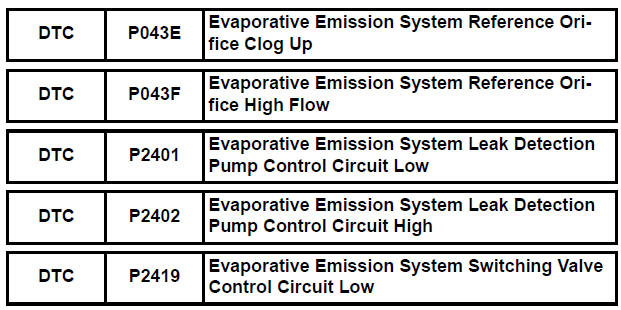

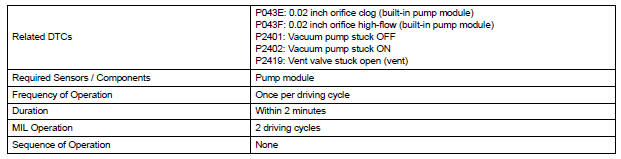

DTC SUMMARY

HINT:

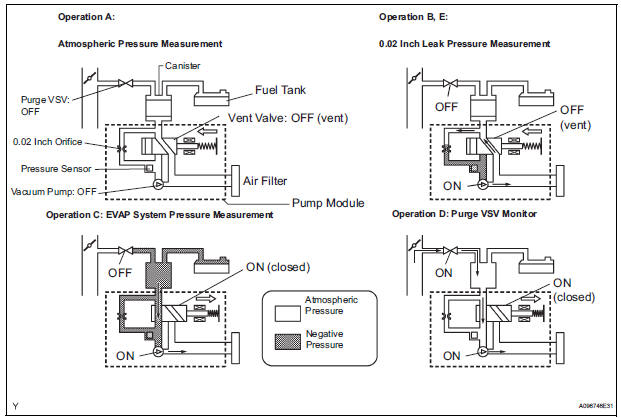

The 0.02 inch orifice is located inside the pump module.

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

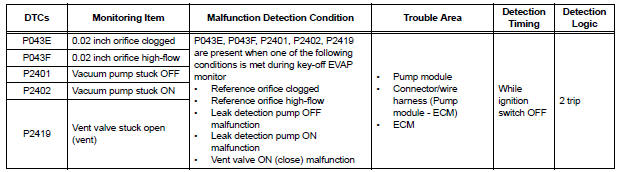

MONITOR DESCRIPTION

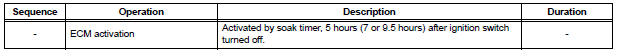

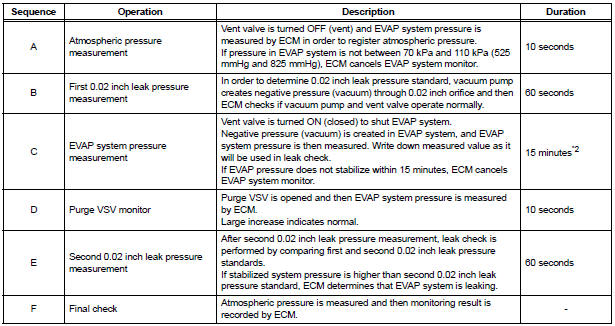

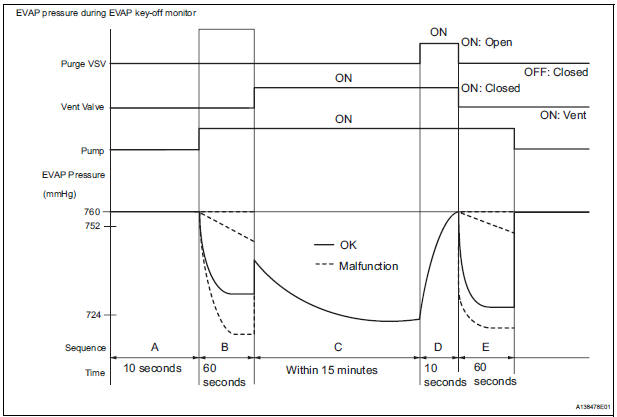

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT:

*1: If the engine coolant temperature is not below 35°C (95°F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°C (95°F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If there is only a small amount of fuel in the fuel tank, stabilizing the EVAP pressure takes longer than usual.

The leak detection pump creates negative pressure through the reference orifice. When the system is normal, the EVAP pressure is in 724 to 752 mmHg* and saturated within a minute.

If not, the ECM interprets this as a malfunction. The ECM will illuminate the MIL and set DTC if this malfunction is detected in consecutive drive cycle.

*: Typical valve

MONITOR STRATEGY

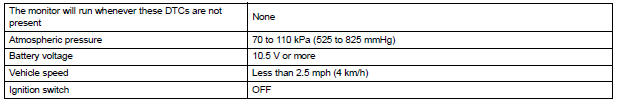

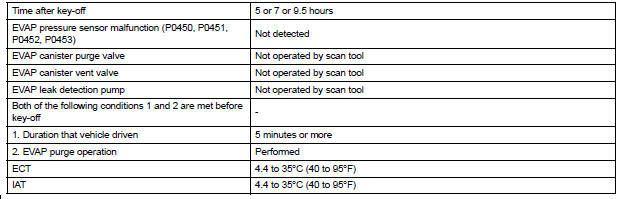

TYPICAL ENABLING CONDITIONS

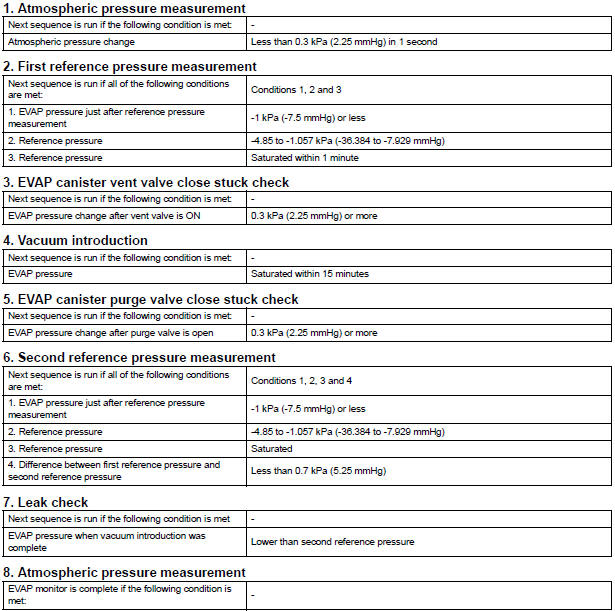

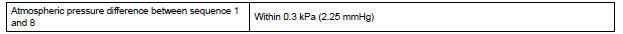

Key-off monitor sequence 1 to 8

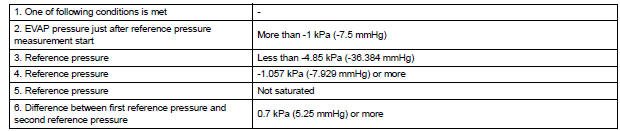

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

Catalyst System Efficiency Below Threshold

Catalyst System Efficiency Below Threshold

MONITOR DESCRIPTION

The ECM uses the sensors mounted in front of and behind the three-way

catalyst (TWC) to monitor its

efficiency. The first sensor, an Air Fuel ratio (A/F) sensor, sends pre- ...

Evaporative Emission Control System Incorrect Purge Flow

Evaporative Emission Control System Incorrect Purge Flow

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission)

System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MO ...

Other materials:

A/F sensor and ho2s monitors

(a) Preconditions

The monitor will not run unless:

2 minutes or more have elapsed since the engine

was started.

The Engine Coolant Temperature (ECT) is 75°C

(167°F) or more.

Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

Air-fuel ratio fe ...

Operation check

1. NOTICE WHEN CHECKING THE FOLLOWING

Power door lock/unlock function:

The wireless door lock control function operates

only when the following 3 conditions are met:

No key is inserted in the ignition key cylinder.

All the doors are closed.

The power door lock sys ...

Diagnosis system

1. CHECK DLC3

The vehicle's ECU uses ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

ope ...