Toyota Sienna Service Manual: Headlight dimmer switch

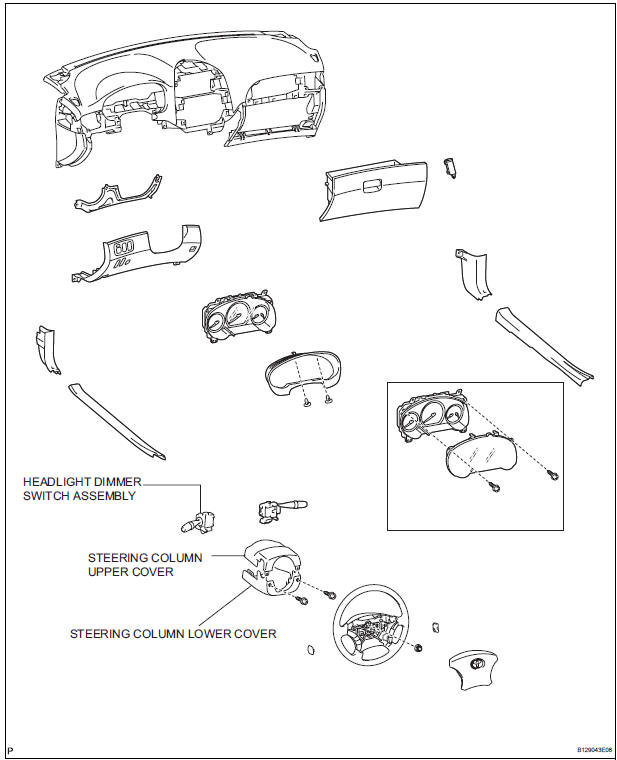

COMPONENTS

REMOVAL

1. REMOVE STEERING COLUMN LOWER COVER

2. REMOVE STEERING COLUMN UPPER COVER

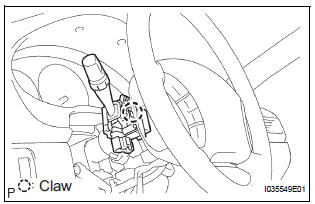

3. REMOVE HEADLIGHT DIMMER SWITCH ASSEMBLY

- Disconnect the connector.

- Release the claw fitting and remove the headlight dimmer switch assembly.

INSPECTION

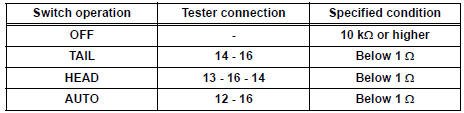

1. HEADLIGHT DIMMER SWITCH ASSEMBLY

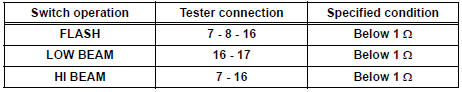

- Inspect light control switch resistance.

- Check that there is resistance between the terminals at each switch position as shown in the chart.

Resistance

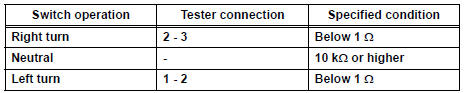

- Inspect light control switch resistance.

- Check that there is resistance between the terminals at each switch position as shown in the chart.

Resistance

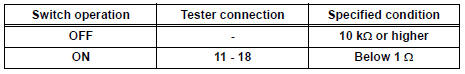

- Inspect light control switch resistance.

- Check that there is resistance between the terminals at each switch position as shown in the chart.

Resistance

- Inspect light control switch resistance.

- Check that there is resistance between the terminals at each switch position as shown in the chart.

Resistance

INSTALLATION

1. INSTALL HEADLIGHT DIMMER SWITCH ASSEMBLY

2. INSTALL STEERING COLUMN UPPER COVER

3. INSTALL STEERING COLUMN LOWER COVER

Vanity light

Vanity light

ON-VEHICLE INSPECTION

1. LH VISOR ASSEMBLY

Inspect vanity light resistance.

check that the resistance exists between the

terminal 1 and the terminal 2 when the light is

oper ...

Turn signal light switch

Turn signal light switch

ON-VEHICLE INSPECTION

1. INSPECT TURN SIGNAL FLASHER CIRCUIT

Measure voltage between the terminals as shown in

the chart below.

Voltage

Connect the connector to turn the si ...

Other materials:

Data list / active test

HINT:

By accessing the DATA LIST displayed on the intelligent

tester, you can perform such functions as reading the values

of switches and sensors without removing any parts. Reading

the DATA LIST as the first step in troubleshooting is one

method to shorten labor time.

1. DATA LIST FOR CENTER ...

Inspection

1. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR

(a) Using a dial gauge , check the runout of the ring

gear.

Maximum runout:

0.07 mm (0.0028 in.)

If the runout is greater than the maximum, replace

the ring gear with a new one.

2. INSPECT DIFFERENTIAL RING GEAR BACKLASH

(a) Using a dial gauge, ...

Circuit opening relay

Inspection

1. INSPECT CIRCUIT OPENING RELAY

Using an ohmmeter, measure the resistance

according to the value(s) in the table below.

Standard resistance

If the result is not as specified, replace the relay. ...