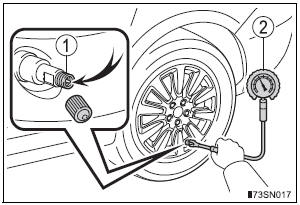

Toyota Sienna 2010-2024 Owners Manual: Inspection and adjustment procedure

- Tire valve

- Tire pressure gauge

- Remove the tire valve cap.

- Press the tip of the tire pressure gauge onto the tire valve.

- Read the pressure using the gauge gradations.

- If the tire inflation pressure is not at the recommended level, adjust

the pressure.

If you add too much air, press the center of the valve to deflate.

- After completing the tire inflation pressure measurement and adjustment, apply soapy water to the valve and check for leakage.

- Put the tire valve cap back on.

Tire inflation pressure check interval

You should check tire inflation pressure every two weeks, or at least once a month.

Do not forget to check the spare.

Effects of incorrect tire inflation pressure

Driving with incorrect tire inflation pressure may result in the following:

- Reduced fuel economy

- Reduced driving comfort and poor handling

- Reduced tire life due to wear

- Reduced safety

- Damage to the drive train

If a tire needs frequent inflating, have it checked by your Toyota dealer.

Instructions for checking tire inflation pressure

When checking tire inflation pressure, observe the following:

- Check only when the tires are cold.

If your vehicle has been parked for at least 3 hours or has not been driven for more than 1 mile or 1.5 km, you will get an accurate cold tire inflation pressure reading.

- Always use a tire pressure gauge.

It is difficult to judge if a tire is properly inflated based only on its appearance.

- It is normal for the tire inflation pressure to be higher after driving as heat is generated in the tire. Do not reduce tire inflation pressure after driving.

- Never exceed the vehicle capacity weight.

Passengers and luggage weight should be placed so that the vehicle is balanced.

| WARNING Proper inflation is critical to save tire performance Keep your tires properly inflated. If the tires are not properly inflated, the following conditions may occur which could lead to an accident resulting in death or serious injury:

|

| NOTICE When inspecting and adjusting tire inflation pressure Be sure to put the tire valve caps back on. If a valve cap is not installed, dirt or moisture may get into the valve and cause an air leak, resulting in decreased tire inflation pressure. |

Tire inflation pressure

Tire inflation pressure

The recommended cold tire inflation pressure and tire size are displayed on

the tire and loading information label. ...

Wheels

Wheels

If a wheel is bent, cracked or heavily corroded, it should be

replaced.

Otherwise, the tire may separate from the wheel or cause a loss

of handling control. ...

Other materials:

Making a call

Once a Bluetooth® phone is registered, you can make a call

using the following procedure:

Dialing

Display the phone screen.

Select the “Dial Pad” tab and enter a phone number.

To delete the input phone number, select

.

For the first digit, you can enter “+” by selecting “&# ...

Zero Point Calibration of Yaw Rate Sensor Undone

DESCRIPTION

The skid control ECU receives signals from the yaw rate sensor via CAN

communication system.

Yaw rate sensor has the built-in deceleration sensor.

If there is trouble in the bus lines between the yaw rate and deceleration

sensor and CAN communication

system, the DTC U0123 ...

Mass or Volume Air Flow Circuit/ Mass or Volume Air Flow Circuit Low Input/

Mass or Volume Air Flow Circuit High Input

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air

flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and to

provide appropriate airfuel

ratio. Inside the MAF meter, there is a heated platinum wire which is ...