Toyota Sienna Service Manual: Installation

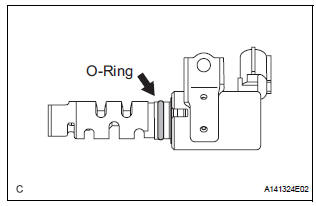

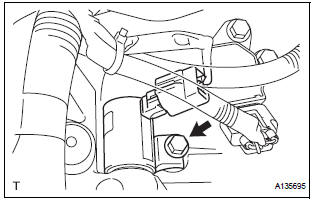

1. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 2 Exhaust Side)

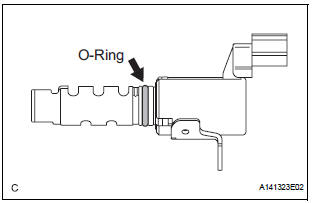

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

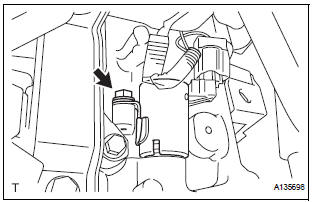

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

- Connect the camshaft timing oil control valve assembly connector

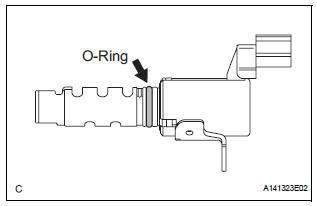

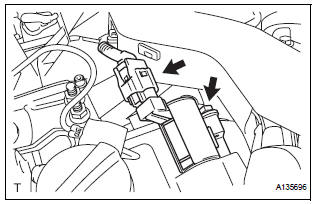

2. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 2 Intake Side)

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) Connect the camshaft timing oil control valve assembly connector

3. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 1 Exhaust Side)

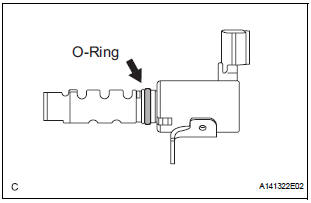

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

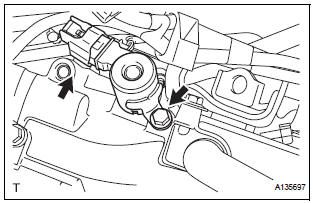

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

- Connect the camshaft timing oil control valve assembly connector

4. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Bank 1 Intake Side)

- Apply a light coat of engine oil to the new O-ring and install it to the camshaft timing oil control valve.

- Install the camshaft timing oil control valve

assembly with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

- Connect the camshaft timing oil control valve assembly connector.

5. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

6. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

7. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

8. INSTALL NO. 1 AIR CLEANER INLET

9. INSTALL NO. 2 AIR CLEANER INLET

10. ADD ENGINE COOLANT

11. INSPECT FOR ENGINE COOLANT LEAK

12. INSPECT FOR ENGINE OIL LEAK

13. INSTALL V-BANK COVER SUB-ASSEMBLY

14. INSTALL FRONT OUTER COWL TOP PANEL SUBASSEMBLY

15. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

Inspection

Inspection

1. INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

Resistance inspection

Using an ohmmeter, measure the resistance

between the terminals.

Resistance:

6.9 to 7.9 ] ...

Throttle body

Throttle body

...

Other materials:

Vehicle Speed Sensor Malfunction

DTC P0500 Vehicle Speed Sensor Malfunction

DTC P0503 Vehicle Speed Sensor "A" Intermittent / Erratic /

High

DESCRIPTION

The cruise control system uses the same vehicle speed signal that is sent to the

ECM for the SFI system.

If DTC P0500 is detected, perform the diagnosis using th ...

Display Panel does not Open, Tilt or Tilts Improperly

INSPECTION PROCEDURE

1 CHECK RADIO AND NAVIGATION ASSEMBLY

Check for foreign matter or obstructions caught in the

moving parts of the panel.

OK:

No obstruction or foreign matter found.

2 CHECK OPERATION

Check if the navigation and audio systems function

properly.

OK:

Naviga ...

Actuator Supply Voltage Circuit / Open

DESCRIPTION

The ECM monitors the output voltage to the throttle actuator. This self-check

ensures that the ECM is

functioning properly. The output voltage is usually 0 V when the ignition switch

is turned off. If the output

voltage is higher than 7 volts when the ignition switch is turned ...