Toyota Sienna Service Manual: Installation

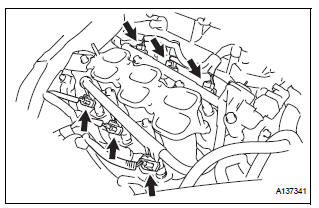

1. INSTALL FUEL INJECTOR ASSEMBLY

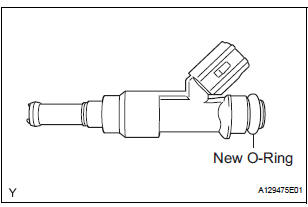

(a) Apply a light coat of spindle oil or gasoline to new Orings, and install them to each injector.

(b) Apply a light coat of spindle oil or gasoline where the fuel delivery pipe contacts the O-ring.

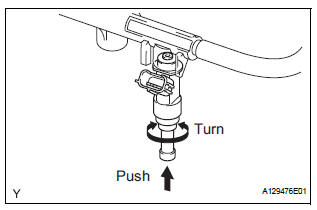

(c) Push the fuel injector while turning it to install the injector in the fuel delivery pipe.

(d) Position the fuel injector connector outward.

NOTICE:

|

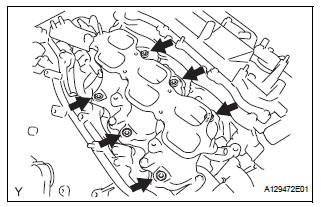

(e) Install 6 new insulators to the intake manifold.

(f) Place the fuel delivery pipe which has the 6 fuel injectors installed to it in position on the intake manifold.

| NOTICE: Be careful not to drop the fuel injectors when installing the fuel delivery pipe. |

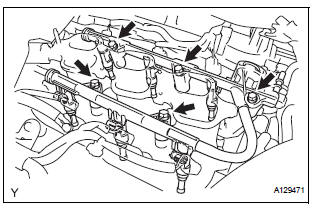

(g) Temporarily install the 5 bolts which are used to hold the fuel delivery pipe to the intake manifold.

| NOTICE: After installing the fuel injectors, check that they turn smoothly. If not, reinstall the injectors with new O-rings. |

(h) Tighten the 5 bolts which are used to hold the fuel delivery pipe to the intake manifold.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(i) Connect the 6 fuel injector connectors.

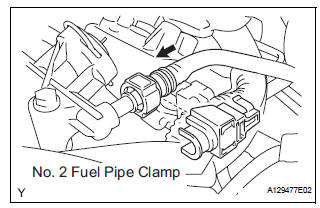

2. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the tube connector onto the pipe until the tube connector makes a "click" sound.

NOTICE:

|

(b) Install the No. 2 fuel pipe clamp.

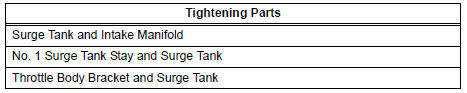

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

|

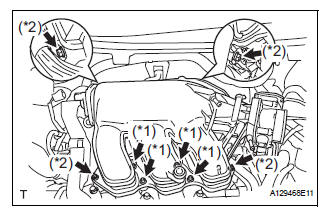

(a) Install a new gasket to the intake air surge tank assembly.

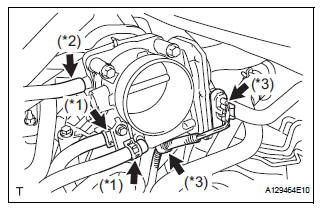

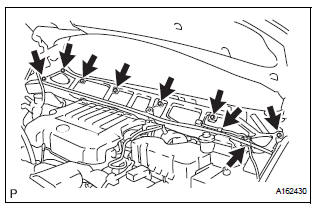

(b) Using a 5 mm hexagon socket wrench, install the 4 bolts. (*1) Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf) (c) Install the intake air surge tank assembly with the 2 nuts and 2 bolts. (*2)

Torque: Nut 16 N*m (163 kgf*cm, 12 ft.*lbf) Bolt 21 N*m (214 kgf*cm, 15 ft.*lbf)

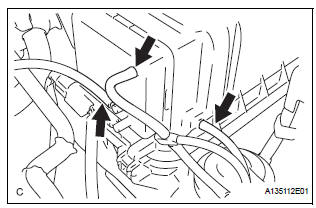

(d) Connect the connector.

(e) Connect the union to check valve hose. (*1) (f) Connect the No. 1 ventilation hose. (*2)

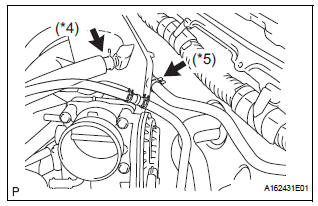

(g) Install the clamp and connect the throttle with motor body assembly connector. (*3) (h) Connect the vapor feed hose assembly. (*4) (i) Connect the 2 water by-pass hoses to the throttle with motor body assembly. (*5)

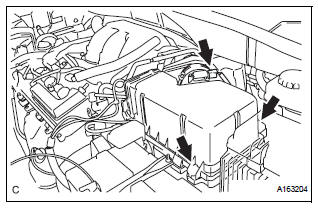

4. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the 2 bolts and air cleaner cap sub-assembly.

(b) Connect the No. 2 ventilation hose and air cleaner hose band.

(c) Connect the vacuum hose (EVAP) to the air cleaner hose.

(d) Connect the 3 vacuum hoses.

5. ADD ENGINE COOLANT (See page CO-7)

6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL 7. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1) 8. INSTALL NO. 1 ENGINE UNDER COVER 9. INSPECT FOR FUEL LEAK (See page FU-7)

10. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63) 11. INSTALL COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT

(a) Install the 7 bolts and the cowl top panel subassembly outer front.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf) (b) Connect the fuel pump resistor connector.

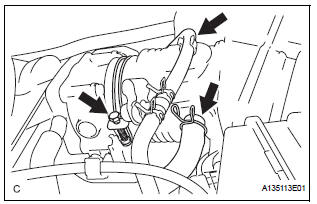

(c) Connect the wire harness clamp.

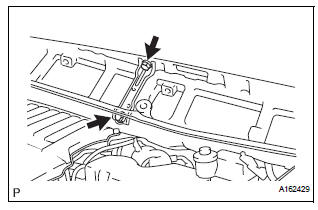

12. INSTALL NO. 1 COWL TOP TO COWL BRACE INNER

(a) Install the 2 bolts and the No.1 cowl top to cowl brace inner.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

13. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (See page WW-6) 14. INSTALL FRONT WIPER ARM LH (See page WW-6) 15. INSTALL FRONT WIPER ARM RH (See page WW-7)

Inspection

Inspection

1. INSPECT FUEL INJECTOR ASSEMBLYV

(A) inspect the injector resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

If the resistance is not a ...

Other materials:

Installation

1. INSTALL BACK DOOR GLASS

Clean and shape the contact surface of the vehicle

body.

Using a knife, cut away any rough adhesive on

the contact surface of the body to ensure the

appropriate surface shape.

HINT:

Leave as much adhesive on the body as

possible.

& ...

Fuel tank

Components

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-1)

2. REMOVE CHARCOAL CANISTER PROTECTOR (See

page FU-30)

3. REMOVE REAR FLOOR NO. 2 CROSSMEMBER BRACE LH

(a) Remove the 2 bolts and the rear floor No. 2

crossmember brace LH.

4. REMOVE FUEL TANK FILLER HOSE COVER ...

Removal

HINT:

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1. PRECAUTION

CAUTION: Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

NOTICE:

Wait for 90 seconds ...