Toyota Sienna Service Manual: Installation

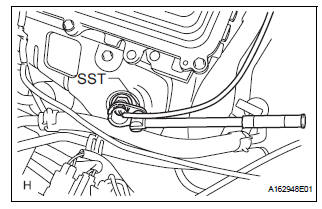

1. INSTALL AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1)

(a) Using SST, install the sensor to the exhaust manifold LH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use with SST 44 N*m (449 kgf*cm, 32 ft.*lbf) for use without SST

HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that SST and wrench are connected in a straight line.

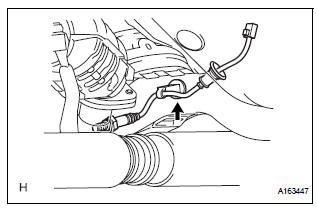

(b) Connect the sensor connector.

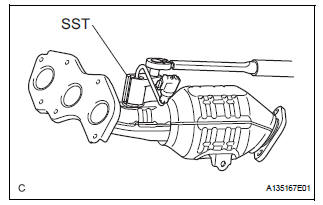

2. INSTALL AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1)

(a) Using SST, install the sensor to the exhaust manifold RH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use with SST 44 N*m (449 kgf*cm, 32 ft.*lbf) for use without SST

HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that SST and wrench are connected in a straight line.

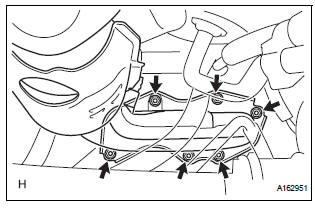

3. INSTALL EXHAUST MANIFOLD RH

(a) Install the exhaust manifold RH with a new gasket and 6 nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

4. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Check compression springs.

(1) Check the compression springs using vernier calipers.

Specified length: 38.86 mm (1.5299 in.)

HINT:

If the result is not as specified, replace the compression spring.

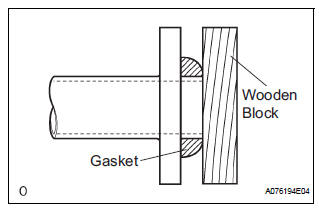

(b) Install the gasket.

(1) Install a new gasket by hand onto the front exhaust pipe assembly.

(2) Using a plastic hammer and wooden block, tap in the new gasket until its surface is flush with the front exhaust pipe.

NOTICE:

|

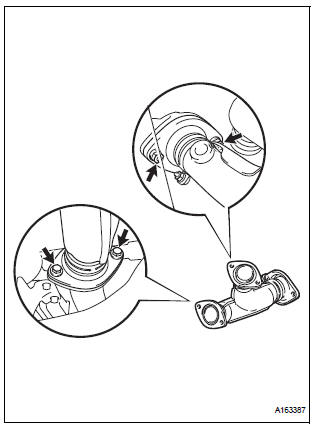

(c) Install 2 new gaskets to the front exhaust pipe assembly.

(d) Install the front exhaust pipe assembly with the 2 nuts and 2 bolts.

Torque: Bolt 43 N*m (440 kgf*cm, 32 ft.*lbf) Nut 62 N*m (632 kgf*cm, 46 ft.*lbf)

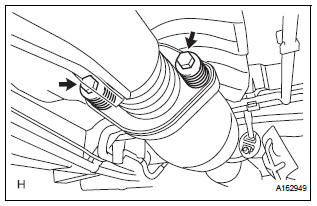

(e) Install the center exhaust pipe assembly with the 2 compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Attach the clip.

(g) Connect the heated oxygen sensor (for Bank 1 Sensor 2) connector.

5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL 6. INSPECT FOR EXHAUST GAS LEAK

Inspection

Inspection

1. Inspect air fuel ratio sensor

(A) measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

...

Heated oxygen sensor (for 2wd)

Heated oxygen sensor (for 2wd)

Components

Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the nagative (-) battery terminal to

...

Other materials:

Hood

Release the lock from the inside of the vehicle to open the hood.

Pull the hood lock release lever.

The hood will pop up slightly.

Pull up the auxiliary catch lever

and lift the hood.

Hold the hood open by inserting

the supporting rod into the slot

WARNING ...

Touch screen gestures

Operations are performed by touching the screen directly with your

finger.

Operation method

Outline

Main use

Touch

Quickly touch and

release once.

Changing and selecting

various settings.

Drag*

Touch the screen

with your ...

Lubrication system

On-vehicle inspection

1. CHECK ENGINE OIL LEVEL

(a) Warm up the engine, stop it and wait 5 minutes. The

oil level should be between the dipstick's low level

mark and full level mark.

If the engine oil level is low, check for leakage and

add oil up to the full level mark.

NOTICE:

D ...