Toyota Sienna Service Manual: Installation

1. INSTALL TRANSFER EXTENSION HOUSING TYPE T OIL SEAL

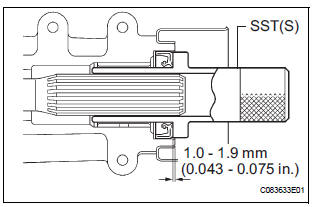

(a) Using SST(s), install anew transfer extension housing type T oil seal to he transfer extension housing sub-assembly at the position show in the illustration.

SST 09325-20010

NOTICE: Do not install the oil seal obliquely.

(b) Apply small amount of MP grease to the oil seal lip.

2. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

HINT: (See page PR-9)

3. FULLY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

HINT: (See page PR-9)

4. INSTALL FRONT EXHAUST PIPE ASSEMBLY

HINT: (See page EX-10)

5. INSTALL TRANSFER DRAIN PLUG

(a) Install the transfer drain plug with anew drain gasket.

Torque: 49 N*m (50 kgf*cm, 36 ft.*lbf)

6. INSTALL TRANSFER CASE NO.1 PLUG

(a) Add oil up to 0 to 5 mm (0 to 0.20 in.) below the lower side of the plug hole.

Oil amount: 0.9 L (0.95 US qts, 0.71 lmp.qts)

NOTICE: When supplying oil, pour do it slowly.

(b) Install the transfer case No. 1 plug with a new gasket No. 1.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

7. CHECK FOR EXHAUST GAS LEAK

Removal

Removal

1. REMOVE TRANSFER CASE NO.1 PLUG (See page

TF-8)

2. REMOVE TRANSFER DRAIN PLUG

(a) Remove the transfer drain plug, drain gasket and

bleed transfer oil.

3. REMOVE EXHAUST PIPE ASSEMBLY

HINT:

(S ...

Propeller shaft

Propeller shaft

...

Other materials:

Installation

1. INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

(a) Install the park/neutral position switch to the manual

valve shaft.

(b) Temporarily install the 2 bolts.

(c) Place a new lock plate and tighten the nut.

Torque: 6.9 N*m (70 kgf*cm, 61 in.*lbf)

(d) Temporarily install the control ...

Auto Up / Down Function does not Operate

DESCRIPTION

If the AUTO UP/DOWN function does not operate, any of the following troubles

may be the cause:

When the PWR fuse or the power window relay (Marking: PWR) is

replaced with new ones, or when

the battery terminal and the connector of the power window master switch are

d ...

Data list / active test

1. DATA LIST

HINT:

Using the intelligent tester to read the DATA LIST allows

the values or states of switches, sensor, actuators and

other items to be read without removing any parts. This

non-intrusive inspection can be very useful because

intermittent conditions or signals may be discovered

...