Toyota Sienna Service Manual: Internal Control Module Random Access Memory (RAM) Error

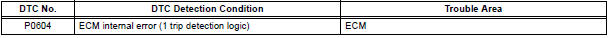

DTC P0604 Internal Control Module Random Access Memory (RAM) Error

DESCRIPTION

The ECM continuously monitors its own internal memory status, internal circuits, and output signals transmitted to the throttle actuator. This self-check ensures that the ECM is functioning properly. If any malfunction is detected, the ECM sets the appropriate DTC and illuminates the MIL.

The ECM memory status is diagnosed by internal mirroring of the main CPU and the sub CPU to detect Random Access Memory (RAM) errors. The two CPUs also perform continuous mutual monitoring. The ECM illuminates the MIL and sets a DTC if: 1) outputs from the two CPUs are different or deviate from the standards, 2) the signals sent to the throttle actuator deviate from the standards, 3) a malfunction is found in the throttle actuator supply voltage, and 4) any other ECM malfunction is found.

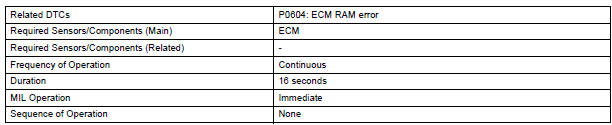

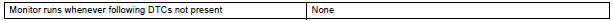

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

ECM RAM errors:

INSPECTION PROCEDURE

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

1 CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0604)

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester on.

- Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

- Read DTCs.

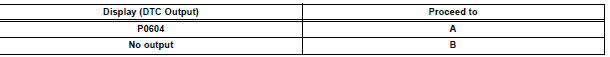

Result

REPLACE ECM

System Voltage

System Voltage

DTC P0560 System Voltage

MONITOR DESCRIPTION

The battery supplies electricity to the ECM even when the ignition switch is

off. This power allows the

ECM to store data such as DTC history, freeze ...

ECM / PCM Processor

ECM / PCM Processor

DTC P0606 ECM / PCM Processor

DESCRIPTION

The ECM continuously monitors its internal processors (CPUs), A/F sensor

transistors and heated oxygen

sensor (HO2S) transistors. This self-check ensures ...

Other materials:

Cruise Main Indicator Light Circuit

DESCRIPTION

When the cruise control main switch is on, the CRUISE main indicator light

and READY indicator light

come on. This indicates the control condition (presence or absence of a vehicle

in front, vehicle-to-vehicle

distance, and set vehicle speed) and fail-safe state through the multip ...

Rear wiper motor and bracket

COMPONENTS

REMOVAL

1. REMOVE REAR WIPER ARM

Remove the rear wiper arm head cap from the rear

wiper arm.

Remove the nut and the rear wiper arm.

2. REMOVE BACK DOOR GARNISH CENTER

3. REMOVE BACK DOOR SIDE GARNISH LH

4. REMOVE POWER BACK DOOR ROD

5. REMOVE BACK DOOR ...

Removal

1. PRECAUTION

CAUTION:

Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE INSTRUMENT PANEL FINISH PANEL SUBASSEMBLY LOWER L ...