Toyota Sienna Service Manual: Pressure Control Solenoid "A" Electrical (Shift Solenoid Valve SL1)

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift

solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.) (See page AX-30).

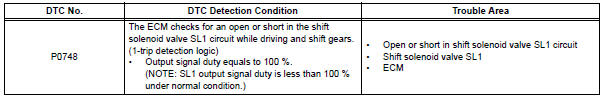

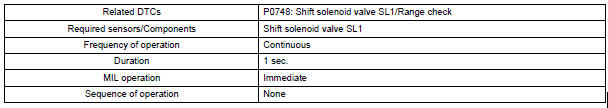

MONITOR STRATEGY

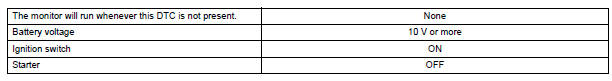

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

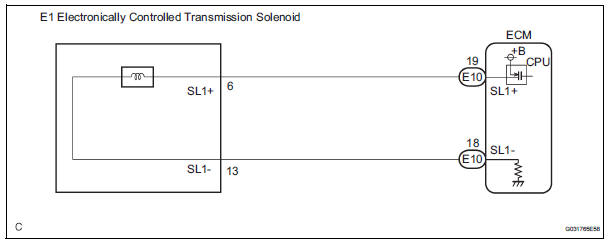

WIRING DIAGRAM

INSPECTION PROCEDURE

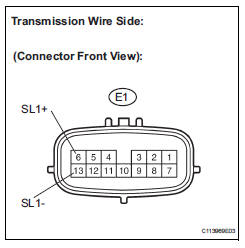

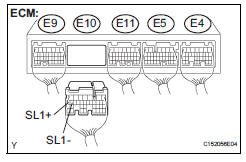

1 INSPECT TRANSMISSION WIRE (SL1)

(a) Disconnect the transmission wire connector from the transaxle.

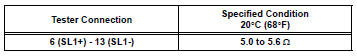

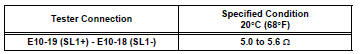

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

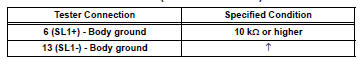

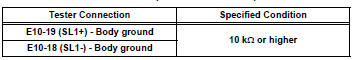

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector to the transaxle.

(b) Disconnect the connector from the ECM.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

REPLACE ECM

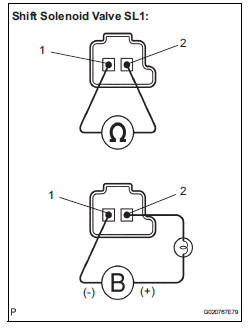

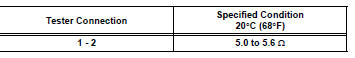

INSPECT SHIFT SOLENOID VALVE SL1

(a) Remove the shift solenoid valve SL1.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

OK: The solenoid makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Pressure Control Solenoid "A" Performance (Shift Solenoid

Valve SL1)

Pressure Control Solenoid "A" Performance (Shift Solenoid

Valve SL1)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to

detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Other materials:

Removal

1. Disconnect cable from negative battery

terminal

2. REMOVE STEERING COLUMN COVER LOWER

(A) insert the key into the ignition key cylinder and

release the steering lock.

(B) turn the steering wheel clockwise to gain access to

the screw and remove the screw.

(c) Turn the steering whe ...

Rear Door ECU RH Communication Stop

DTC B1216 Rear Door ECU RH Communication Stop

DESCRIPTION

DTC B1216 is output when communication between the power slide door ECU RH

and the multiplex

network gateway ECU stops for more than 10 seconds.

DTC No.

DTC Detection Condition

Trouble Area

B1216

...

If you have a flat tire

(vehicles with a compact

spare tire)

Your vehicle is equipped with a spare tire. The flat tire can be

replaced with the spare tire.

For details about tires:

WARNINGIf you have a flat tire

Do not continue driving with a flat tire.

Driving even a short distance with a flat tire can damage the tire and

the

wheel ...