Toyota Sienna Service Manual: Reassembly

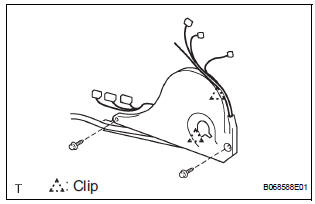

1. INSTALL REAR DOOR WIRE SUB-ASSEMBLY LH

- Install the wire.

NOTICE: When installing the wire, push the areas where the clips are installed in order to prevent damage and deformation.

- Install the 2 screws.

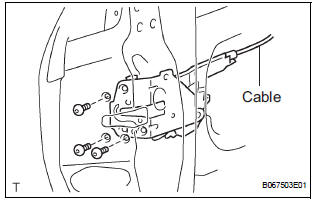

2. INSTALL REAR DOOR LOCK ASSEMBLY LH

- Apply MP grease to the sliding and rotating areas of the lock.

- Apply adhesive to the threads of the screws.

Adhesive: Part No. 08833-00070, THREE BOND 1324 or equivalent

- Install the lock to the door panel with the 3 screws.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

- Connect the cable.

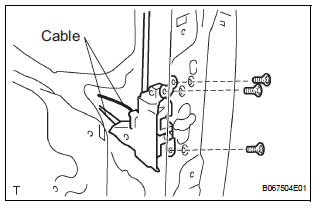

3. INSTALL SLIDE DOOR LOCK ASSEMBLY FRONT LH

- Apply MP grease to the sliding and rotating areas of the lock.

- Apply adhesive to the threads of the screws.

Adhesive: Part No. 08833-00070, THREE BOND 1324 or equivalent

- Install the lock front to the door panel with the 3

screws.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

- Connect the 2 cables.

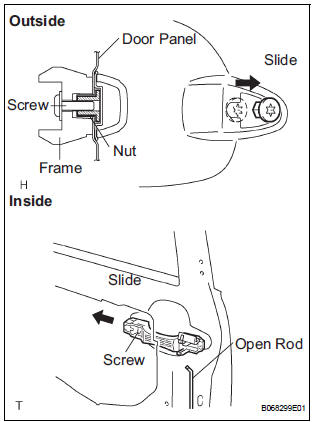

4. INSTALL REAR DOOR OUTSIDE HANDLE FRAME SUB-ASSEMBLY LH

- Apply MP grease to the sliding and rotating parts of the outside handle frame.

- Slide the outside handle frame in the direction indicated by the arrow mark in the illustration.

- Using a torx socket wrench (T30), install the outside

handle frame with the screw.

Torque: 7.0 N*m (71 kgf*cm, 62 in.*lbf) NOTICE: Insert a cover between the nut and the door panel.

- Install the open rod.

Adjustment

Adjustment

HINT:

On the RH side, use the same procedures as on the LH side.

1. INSPECT SLIDE DOOR PANEL SUB-ASSEMBLY LH

Check that the clearance is within the standard

range.

Standard

2. ADJU ...

Reassembly

Reassembly

1. INSTALL REAR DOOR WIRE SUB-ASSEMBLY LH

Install the wire.

NOTICE:

When installing the wire, push the areas where

the clips are installed in order to prevent

damage and deformation.

...

Other materials:

Installation

1. INSTALL FRONT DOOR WINDOW FRAME MOULDING

Remove the tape from the front door window frame

moulding.

Clean the contact surface of the vehicle body with

white gasoline.

Clean the outer circumference of the front door

window frame moulding with white gasoline.

Apply new double-si ...

Manual Up / Down and Auto Down Function does not Operate on

Driver Side

DESCRIPTION

If the manual UP/DOWN function does not operate, no power may be supplied to

the power window

master switch or the power window motor. The power window master switch itself

or the wire harness may

be malfunctioning.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT FUSE (P/W)

...

Inspection

1. INSPECT REAR DRIVE SHAFT ASSEMBLY LH

(a) Check that there is no remarkable play in the radial

direction of the outboard joint.

(b) Check that the inboard joint slides smoothly in the

thrust direction.

(c) Check that there is no remarkable play in the radial

direction of the inboard ...