Toyota Sienna Service Manual: Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL 2. DRAIN ENGINE COOLANT 3. REMOVE FRONT WIPER ARM HEAD CAP (See page WW-4) 4. REMOVE FRONT WIPER ARM RH (See page WW-4) 5. REMOVE FRONT WIPER ARM LH (See page WW-4) 6. REMOVE COWL TOP VENTILATOR LOUVER SUBASSEMBLY (See page WW-4) 7. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (See page WW-4) 8. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER (See page FU-13) 9. REMOVE COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT (See page FU-13) 10. REMOVE NO. 1 ENGINE UNDER COVER 11. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28) 12. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page FU-13) 13. REMOVE INTAKE AIR SURGE TANK ASSEMBLY (See page FU-14) 14. REMOVE NO. 1 SURGE TANK STAY

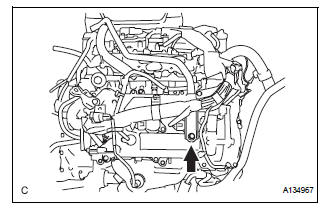

(a) Remove the 2 bolts and nut and disconnect the 2 harness clamps.

(b) Remove the bolt and No. 1 surge tank stay.

15. REMOVE IGNITION COIL ASSEMBLY

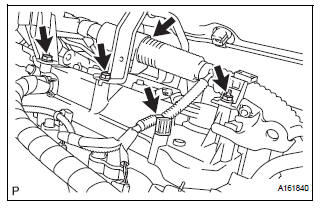

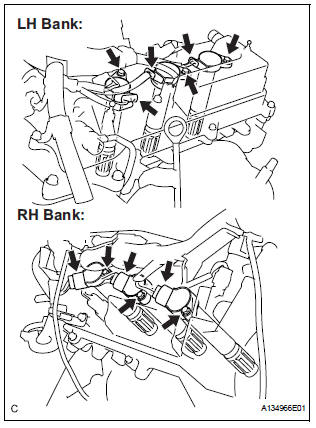

(a) Disconnect the 6 ignition coil connectors.

(b) Remove the 6 bolts and 6 ignition coils.

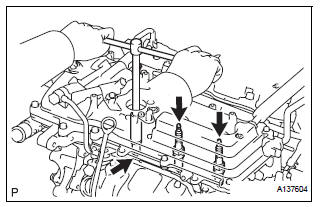

16. REMOVE SPARK PLUG

(a) Remove the 6 spark plugs.

On-vehicle inspection

On-vehicle inspection

NOTICE:

In this section, the terms "cold" and "hot" refer to the

temperature of the coils. "Cold" means approximately -

10°C (14°F) to 50°C (122°F). & ...

Installation

Installation

1. INSTALL SPARK PLUG

(a) Install the 6 spark plugs.

Torque: 18 N*m (183 kgf*cm, 13 ft.*lbf)

2. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coils with the 6 bolts.

Torqu ...

Other materials:

Front passenger side power

window switch

Inspection

1. INSPECT POWER WINDOW REGULATOR SWITCH ASSEMBLY

Check the resistance between the switch terminals

when the switch is operated.

Standard

If the result is not as specified, replace the switch

assembly. ...

Room light assembly

ON-VEHICLE INSPECTION

1. ROOM LIGHT ASSEMBLY NO.2

Check that the resistance exists between the

terminals.

Resistance:

Below 1 Ω

2. INTERIOR DOME LIGHT SWITCH ASSEMBLY

Check that there is resistance between the

terminals at each switch position as shown in the

cha ...

Installation

HINT:

Install the RH side by the same procedure as the LH side.

1. INSTALL REAR SPEED SENSOR

(a) Clean the contacting surface of the axle hub and a

new skid control sensor.

NOTICE:

Keep the sensor rotor clean.

(b) Place the speed sensor on the axle hub so that the

connector is positioned ...