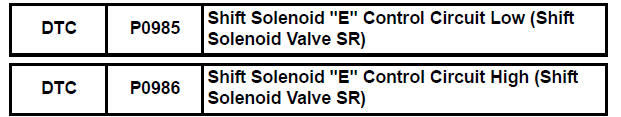

Toyota Sienna Service Manual: Shift Solenoid "E" Control Circuit

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift

solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

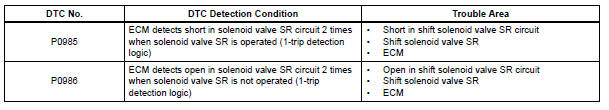

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.) (See page AX-30).

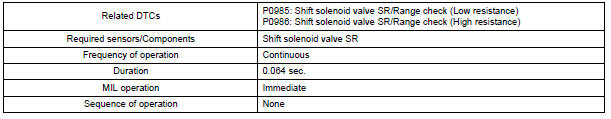

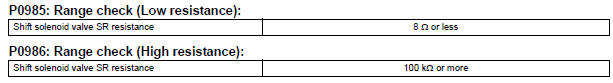

MONITOR STRATEGY

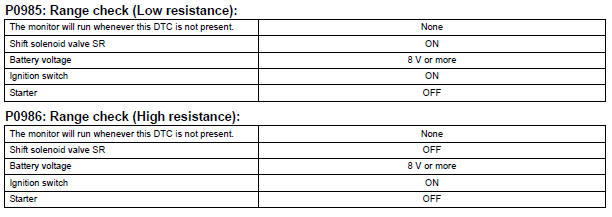

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

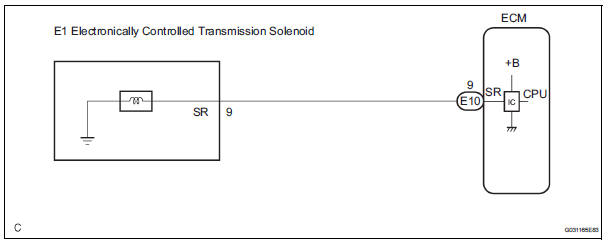

WIRING DIAGRAM

INSPECTION PROCEDURE

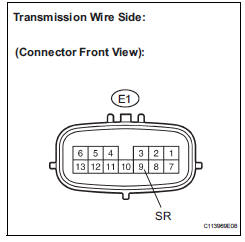

1 INSPECT TRANSMISSION WIRE (SR)

(a) Disconnect the transmission wire connector from the transaxle.

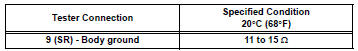

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

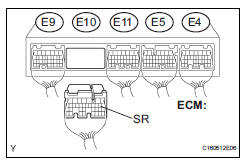

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector to the transaxle.

(b) Disconnect the connector from the ECM.

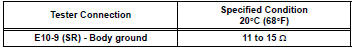

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE ECM

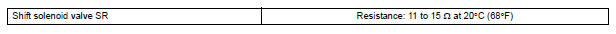

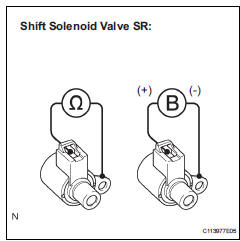

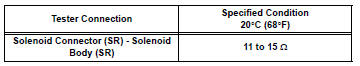

3 INSPECT SHIFT SOLENOID VALVE SR

(a) Remove the shift solenoid valve SR.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead to the terminal of the solenoid connector, and the negative (-) lead to the solenoid body.

OK: The solenoid makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Shift Solenoid "D" Control Circuit

Shift Solenoid "D" Control Circuit

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by ...

Pressure Control Solenoid "D" Performance (Shift

Solenoid Valve SLT)

Pressure Control Solenoid "D" Performance (Shift

Solenoid Valve SLT)

SYSTEM DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for

smooth transmission operation

based on signals from the throttle position sensor and the vehicle spee ...

Other materials:

Removal

1. DISCONNECT BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

HINT:

(See page IP-6)

3. REMOVE FRONT DOOR SCUFF PLATE RH

HINT:

(See page IP-6)

4. REMOVE COWL SIDE TRIM BOARD LH

HINT:

(See page IP-6)

5. REMOVE COWL SIDE TRIM BOARD RH

HINT:

(See page IP-6)

6. REMOVE INSTRUMEN ...

Throttle Actuator Control System

DTC P2111 Throttle Actuator Control System - Stuck Open

DTC P2112 Throttle Actuator Control System - Stuck

Closed

DESCRIPTION

The throttle actuator is operated by the ECM, and opens and closes the

throttle valve using the gears.

The opening angle of the throttle valve is detected by the Thr ...

Installation

1. INSTALL NO. 2 REAR SEAT OUTER BELT ASSEMBLY

NOTICE:

Do not disassemble the retractor.

Check the degree of tilt when the No. 2 rear seat

outer belt assembly begins to lock the ELR.

Check that the belt does not lock within 15 of

tilt in all directions but that the be ...