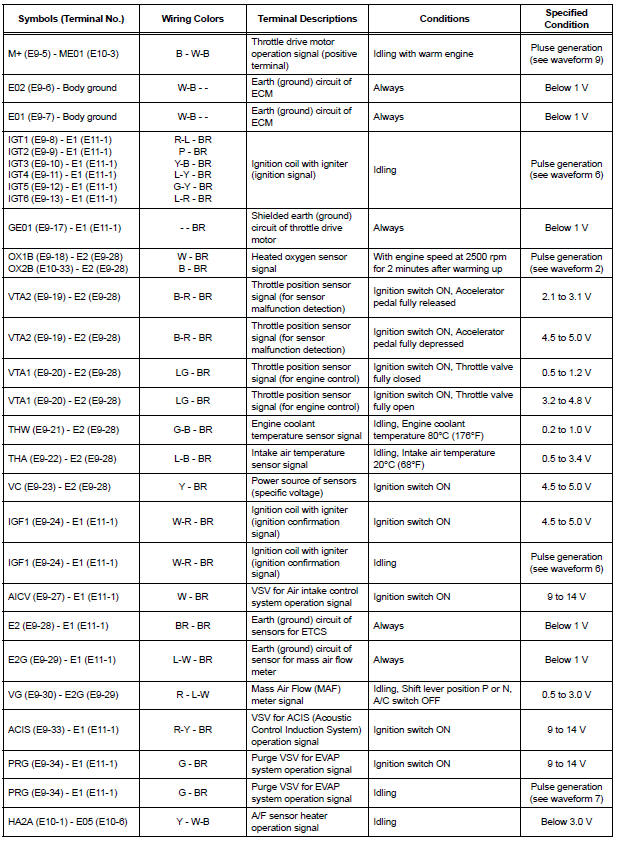

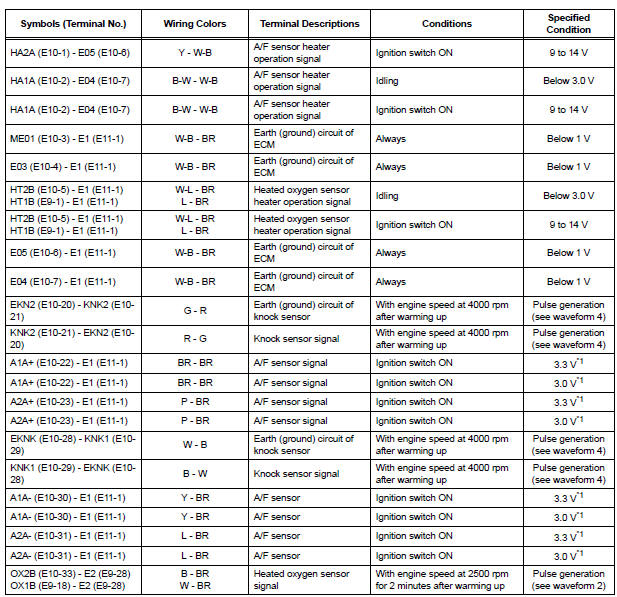

Toyota Sienna Service Manual: Terminals of ecm

Sfi system

Hint:

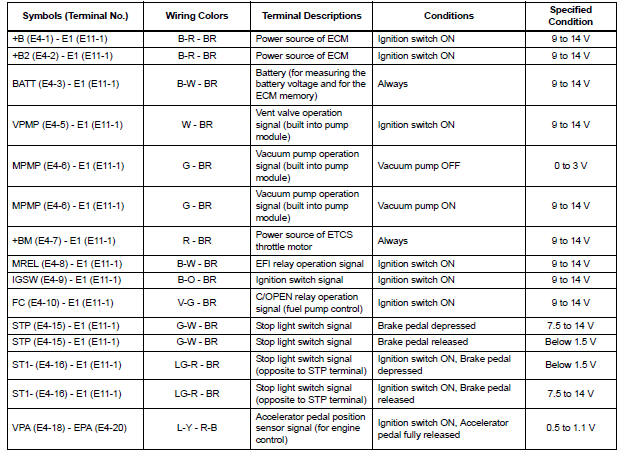

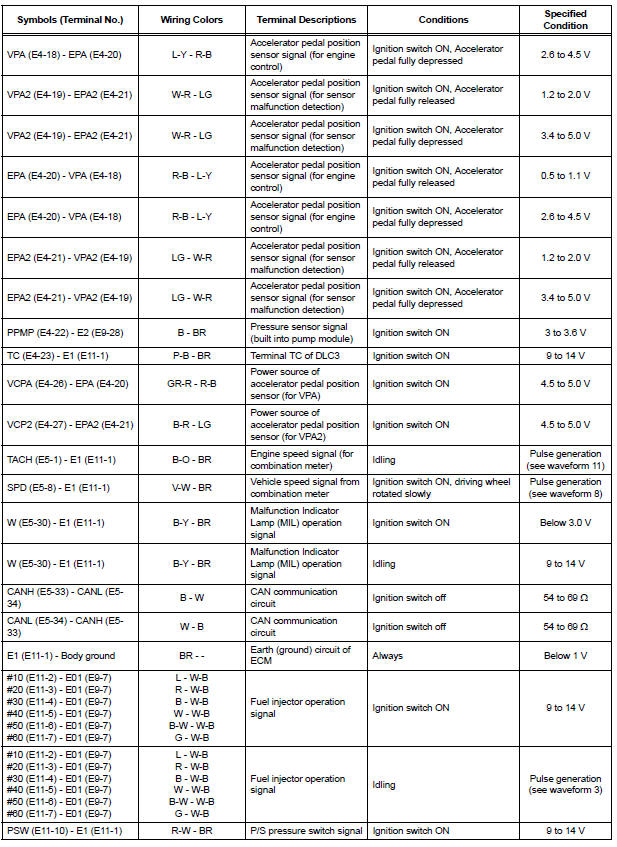

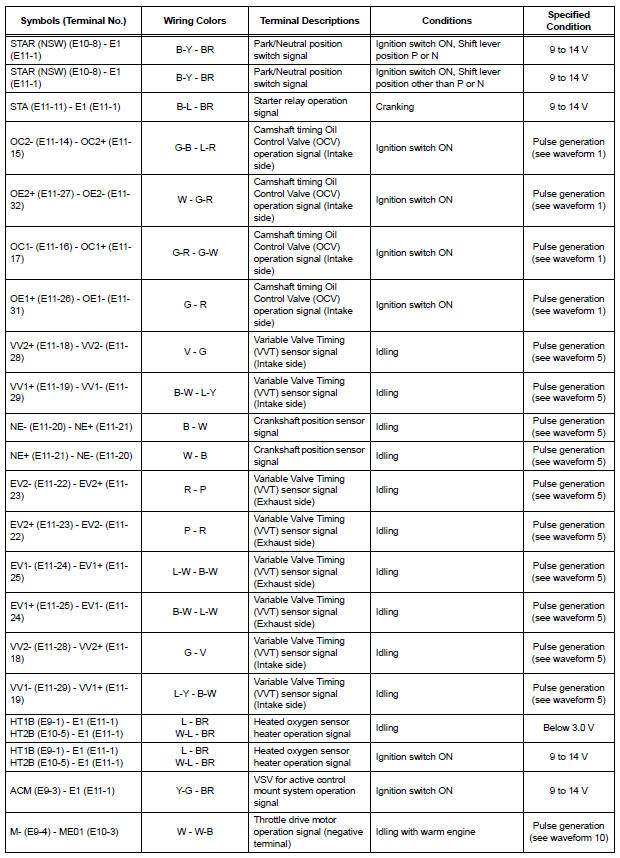

The standard normal voltage between each pair of the ECM terminals is shown in the table below. The appropriate conditions for checking each pair of the terminals are also indicated.

The check results should be compared with the standard normal voltage for that pair of terminals, listed in the "Specified Condition" column.

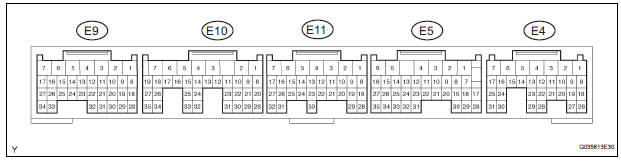

The illustration above can be used as a reference to identify the ECM terminal locations.

*1: The ECM terminal voltage is constant regardless of the output voltage from the sensor.

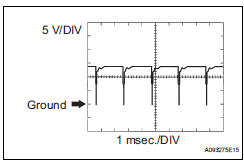

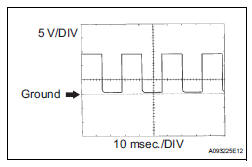

(a) WAVEFORM 1

(1) Camshaft Timing Oil Control Valve (OCV)

operation signal

HINT:

The wavelength becomes shorter as the engine rpm increases.

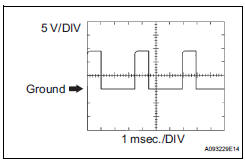

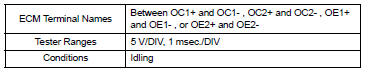

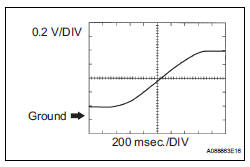

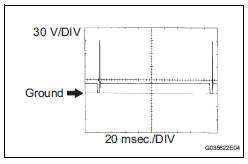

(b) WAVEFORM 2

(1) Heated oxygen sensor signal

HINT:

In the DATA LIST, item O2S B1S2 shows the ECM input values from the heated oxygen sensor.

(c) WAVEFORM 3

(1) Fuel injector operation signal

HINT:

The wavelength becomes shorter as the engine rpm increases.

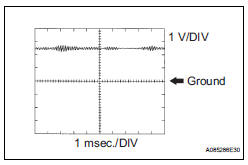

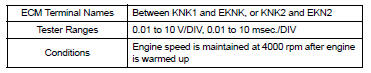

(d) WAVEFORM 4

(1) Knock sensor signal

HINT:

- The wavelength becomes shorter as the engine rpm increases.

- The waveforms and amplitudes displayed differ slightly depending on the vehicle.

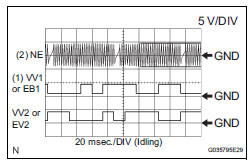

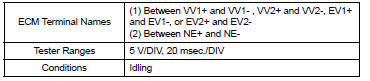

(e) WAVEFORM 5

(1) Variable Valve Timing (VVT) sensor signal (1)

(2) Crankshaft position sensor signal (2)

HINT:

The wavelength becomes shorter as the engine rpm increases.

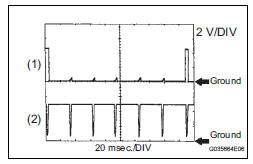

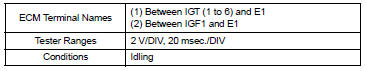

(f) WAVEFORM 6

(1) Igniter IGT signal (from ECM to igniter) (1)

(2) Igniter IGF signal (from igniter to ECM) (2)

HINT:

The wavelength becomes shorter as the engine rpm increases.

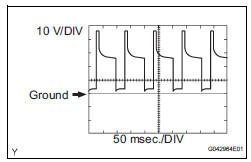

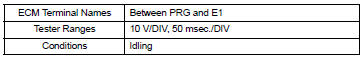

(g) WAVEFORM 7

(1) Purge VSV for EVAP system operation signal

HINT:

If the waveform is not similar to that shown in the illustration, check the waveform again after idling for 10 minutes or more.

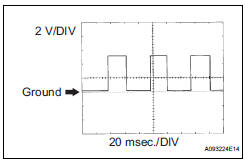

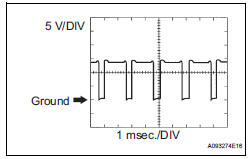

(h) WAVEFORM 8

(1) Vehicle speed signal

HINT:

- The wavelength becomes shorter as the vehicle speed increases.

- Depending on the vehicle, the output waveform voltage may rise to 12 V if influenced by optionally installed systems.

(i) WAVEFORM 9

(1) Throttle drive motor operation signal (positive

terminal)

HINT:

The duty ratio varies depending on the throttle actuator operation.

(j) WAVEFORM 10

(1) Throttle drive motor operation signal (negative

terminal)

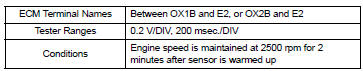

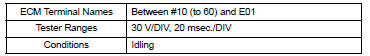

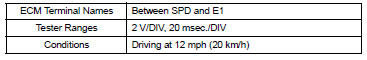

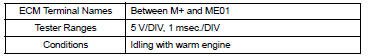

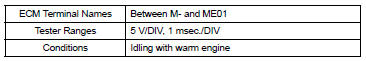

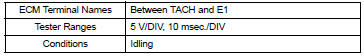

(k) WAVEFORM 11

1) Engine speed signal

HINT:

The wavelength becomes shorter as the engine rpm increases.

Problem symptoms table

Problem symptoms table

HINT:

When a malfunction is not confirmed by a DTC (Diagnostic

Trouble Code) check and the cause of problem cannot be

identified through a basic inspection, troubleshoot according

to the priority ...

Diagnosis system

Diagnosis system

DESCRIPTION

(a) When troubleshooting OBD II (On-Board

Diagnostics) vehicles, an intelligent tester

(complying with SAE J1987) must be connected to

the DLC3 (Data Link Connector 3) of the vehicle.

...

Other materials:

Speed sensor check (when using sst check wire)

(a) Check the speed sensor signal.

(1) Drive the vehicle straight forward. Drive the

vehicle at a speed of 45 km/h (28 mph) or higher

for several seconds and check that the ABS

warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun or the stee ...

Precaution

Keep in mind the following points when inspecting the

dynamic laser cruise control system.

As there is a limitation on the vehicle-to-vehicle distance

controlling capability, do not overly rely on the dynamic

laser cruise control system.

Do not neglect to pay constant attentio ...

DTC check / clear

NOTICE:

All the stored DTCs and freeze frame data are erased if:

the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned from ON

to ACC or off while in check mode.

Before changing modes, always check and make a note

of any DTCs and fr ...