Toyota Sienna Service Manual: Terminals of ECU

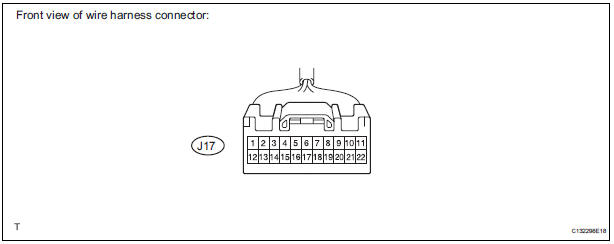

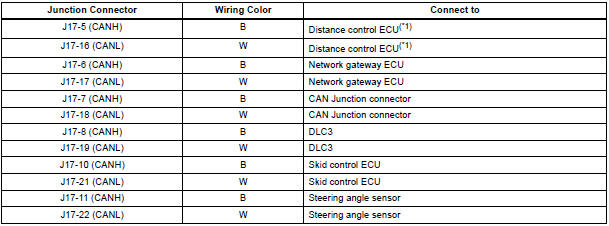

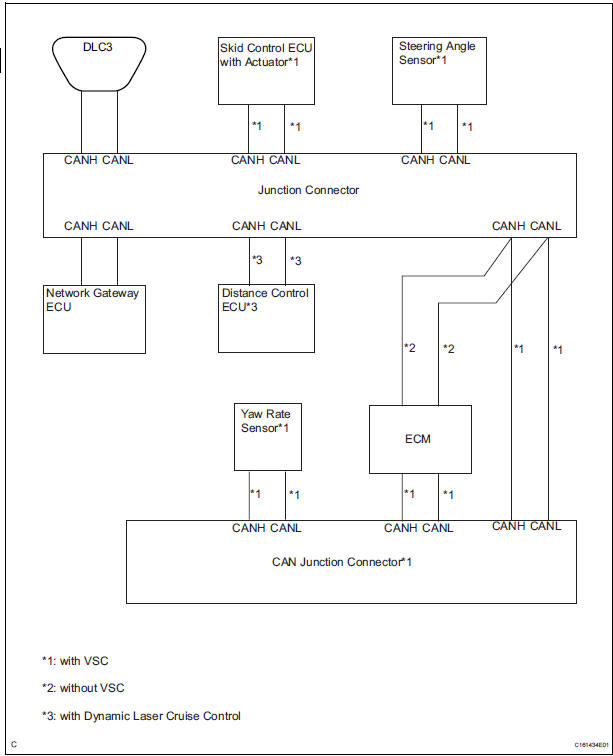

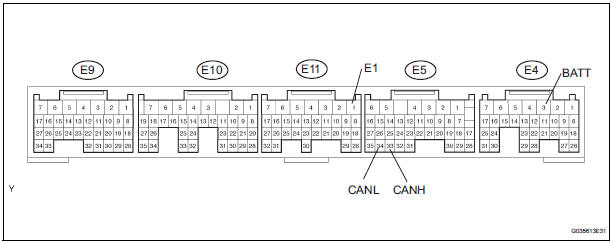

1. JUNCTION CONNECTOR

- Junction connector

with VSC

HINT: *1: with Dynamic laser cruise control

without VSC

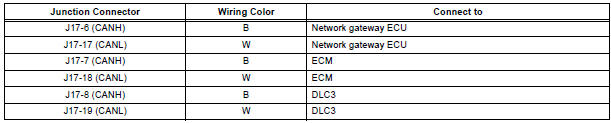

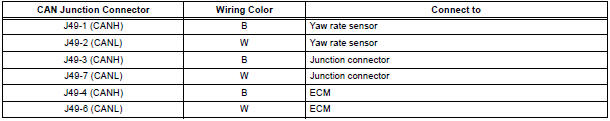

- CAN junction connector (with VSC)

with VSC

- The connection diagram of the components which are connected to the CAN junction connector.

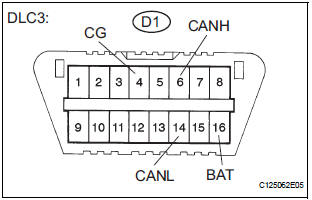

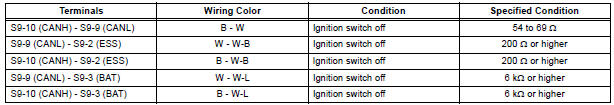

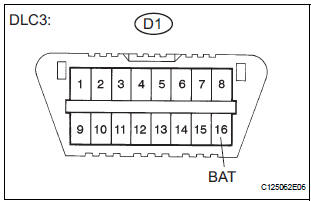

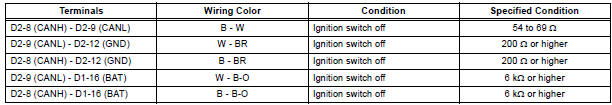

2. DLC3

- Measure the resistance according to the value(s) in the table below.

Standard resistance

3. ECM

- Disconnect the connector from the ECM.

- Measure the resistance according to the value(s) in the table below

Standard resistance

4. NETWORK GATEWAY ECU

- Disconnect the connector from the netwark gateway ECU.

- Measure the resistance according to the value(s) in the table below

Standard resistance

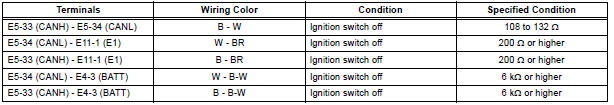

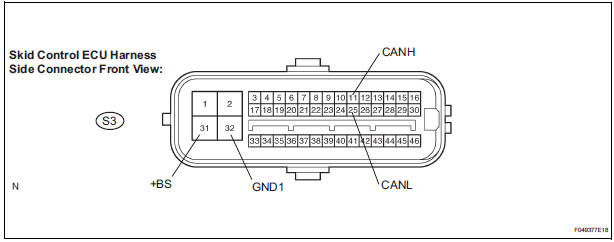

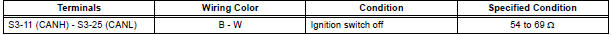

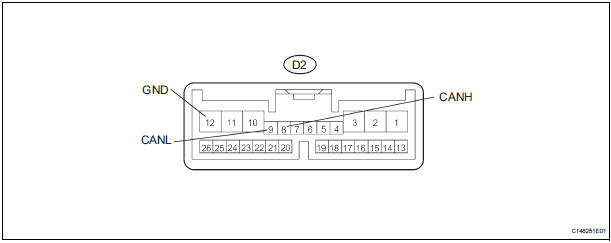

5. SKID CONTROL ECU WITH ACTUATOR

- Disconnect the connector from the skid control ECU with actuator.

- Measure the resistance according to the value(s) in the table below

Standard resistance

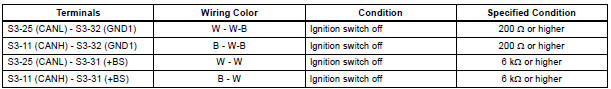

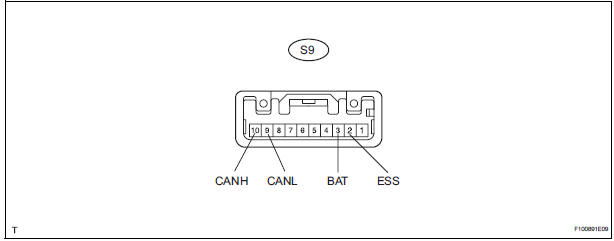

6. STEERING ANGLE SENSOR

- Disconnect the connector from the steering angle sensor.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

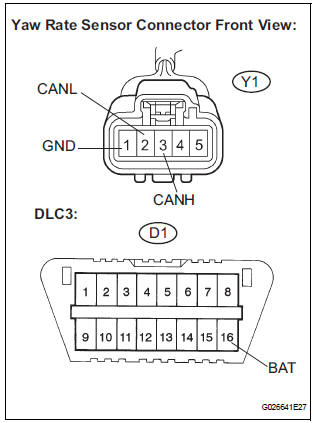

7. YAW RATE SENSOR

- Disconnect the connector from the yaw rate sensor.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

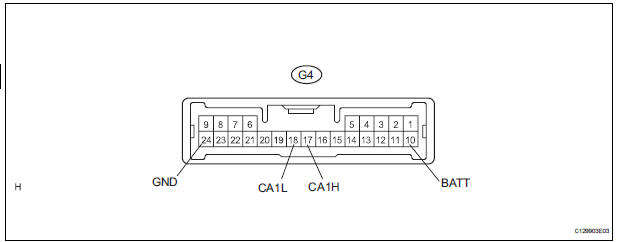

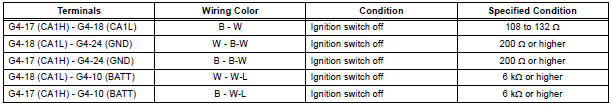

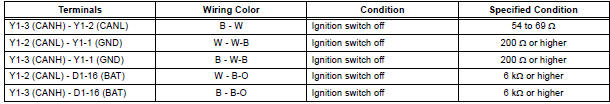

8. DISTANCE CONTROL ECU

- Disconnect the connector from the distance control ECU.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Problem symptoms table

Problem symptoms table

RESULT LIST OF CHECK CAN BUS LINE

Symptom

Suspected Area

All ECUs and sensors connected to the CAN

communication system are not displayed on intelligent

tester

CAN ...

Diagnosis system

Diagnosis system

1. BUS CHECK

Select "BUS CHECK" from the "OBD/MOBD

MENU" screen.

HINT:

The ECUs and sensors that are properly connected

to the CAN communication system can be displaye ...

Other materials:

Air fuel ratio sensor relay

INSPECTION

1. INSPECT AIR FUEL RATIO SENSOR RELAY

Using an ohmmeter, measure the resistance

according to the value(s) in the table below.

Standard resistance

If the result is not as specified, replace the relay. ...

Power steering

Sst

Recommended tools

EQUIPMENT

LUBRICANT

SSM

...

Installation

1. INSTALL REAR SEAT 3 POINT TYPE BELT

ASSEMBLY (for 8-Passenger)

HINT: Refer to the instructions for reassembly of the rear

No. 1 seat assembly (for center seat).

Install the rear seat 3 point type belt assembly with

the bolt.

Torque: 42 N*m (430 kgf*cm, 31 ft.*lbf)

2. INSTALL ...