Toyota Sienna Service Manual: Throttle / Pedal Position Sensor

HINT:

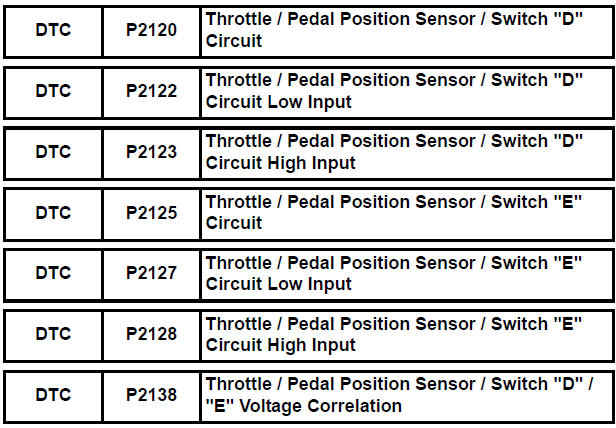

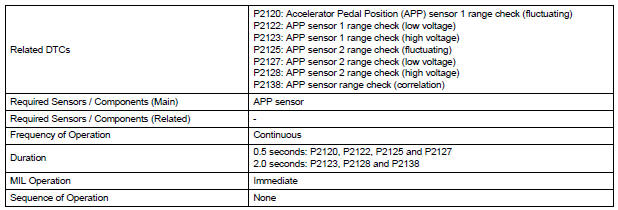

These DTCs relate to the Accelerator Pedal Position (APP) sensor.

DESCRIPTION

HINT:

This ETCS (Electronic Throttle Control System) does not use a throttle cable.

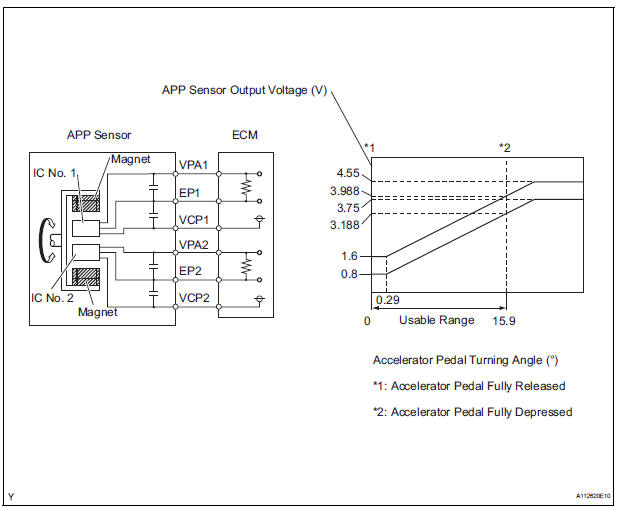

The Accelerator Pedal Position (APP) sensor is integrated with the accelerator pedal bracket and has 2 sensor circuits: VPA (main) and VPA2 (sub). This sensor is a non-contact type, and uses Hall-effect elements, in order to yield accurate signals, even in extreme driving conditions, such as at high speeds as well as very low speeds. The voltage, which is applied to terminals VPA and VPA2 of the ECM, varies between 0 V and 5 V in proportion to the operating angle of the accelerator pedal (throttle valve). A signal from VPA indicates the actual accelerator pedal opening angle (throttle valve opening angle) and is used for engine control. A signal from VPA2 conveys the status of the VPA circuit and is used to check the APP sensor itself.

The ECM monitors the actual accelerator pedal opening angle (throttle valve opening angle) through the signals from VPA and VPA2, and controls the throttle actuator according to these signals.

HINT:

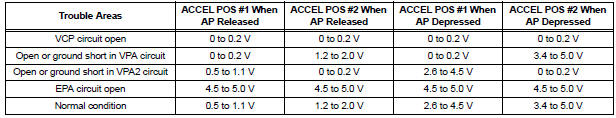

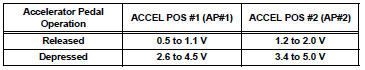

When any of these DTCs are set, check the APP sensor voltage by selecting the following menu items on the intelligent tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / ACCEL POS #1 and ACCEL POS #2.

HINT:

- Accelerator pedal positions are expressed as voltages.

- AP denotes Accelerator Pedal.

MONITOR DESCRIPTION

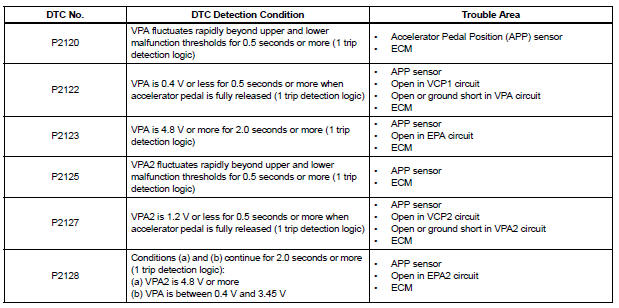

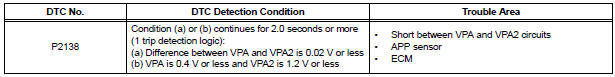

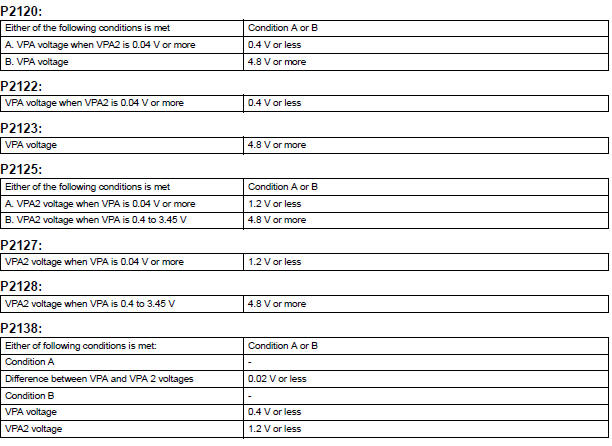

When either of the voltage outputs of VPA or VPA2 deviates from the standard range, or the difference between the voltage outputs of the 2 sensor circuits is less than the threshold, the ECM determines that there is a malfunction in the APP sensor. The ECM then illuminates the MIL and sets a DTC.

Example: When the voltage output of VPA drops below 0.4 V for more than 0.5 seconds when the accelerator pedal is fully depressed, DTC P2122 is set.

If the malfunction is not repaired successfully, a DTC is set 2 seconds after the engine is next started.

MONITOR STRATEGY

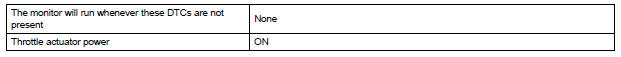

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

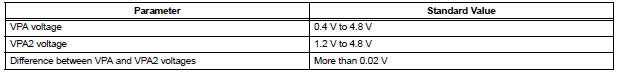

COMPONENT OPERATING RANGE

FAIL-SAFE

When any of DTCs P2120, P2121, P2122, P2123, P2125, P2127, P2128 and P2138 are set, the ECM enters fail-safe mode. If either of the 2 sensor circuits malfunctions, the ECM uses the remaining circuit to calculate the accelerator pedal position to allow the vehicle to continue driving. If both of the circuits malfunction, the ECM regards the accelerator pedal as being released. As a result, the throttle valve is closed and the engine idles.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is turned off.

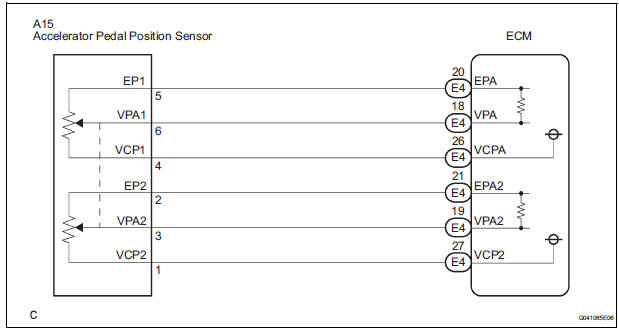

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

1 READ VALUE OF INTELLIGENT TESTER (ACCEL POS #1 AND ACCEL POS #2)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL / ACCEL POS #1 and ACCEL POS #2.

(d) Read the values displayed on the tester.

Standard voltage

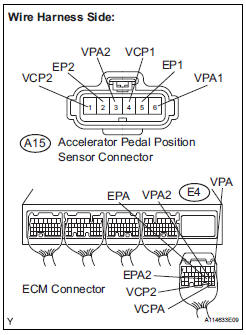

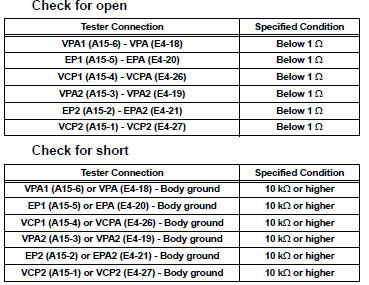

2 CHECK HARNESS AND CONNECTOR (ACCELERATOR PEDAL POSITION SENSOR - ECM)

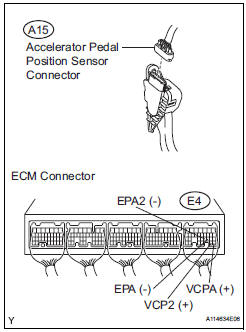

(a) Disconnect the A15 Accelerator Pedal Position (APP) sensor connector.

(b) Disconnect the E4 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance :

(d) Reconnect the APP sensor connector.

(e) Reconnect the ECM connector.

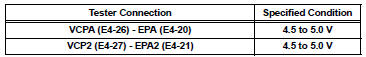

3 INSPECT ECM (VCPA AND VCP2 VOLTAGE)

(a) Disconnect the A15 APP sensor connector.

(b) Turn the ignition switch to the ON position.

(c) Measure the voltage according to the value(s) in the table below.

Standard voltage

(d) Reconnect the APP sensor connector.

4 REPLACE ACCELERATOR PEDAL ROD

(a) Replace the accelerator

pedal rod assembly (See page

ES-502).

(a) Replace the accelerator

pedal rod assembly (See page

ES-502).

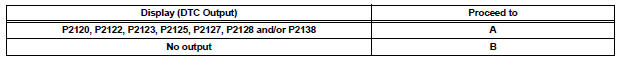

5 CHECK WHETHER DTC OUTPUT RECURS (ACCELERATOR PEDAL POSITION SENSOR DTCS)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the tester on.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine.

(e) Allow the engine to idle for 15 seconds.

(f) Select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

(g) Read the DTCs.

Result

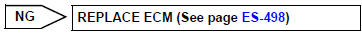

REPLACE ECM (See page ES-498)

Throttle Actuator Control Throttle Body Range / Performance

Throttle Actuator Control Throttle Body Range / Performance

DESCRIPTION

The Electronic Throttle Control System (ETCS) is composed of the throttle

actuator, Throttle Position (TP)

sensor, Accelerator Pedal Position (APP) sensor, and ECM. The ECM operate ...

Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance

Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance

HINT:

This DTC relates to the Accelerator Pedal Position (APP) sensor.

DESCRIPTION

Refer to DTC P2120 (See page ES-343).

MONITOR DESCRIPTION

The accelerator pedal position sensor is mount ...

Other materials:

Precaution

1. Handling precautions on steering system

(a) Care must be taken when replacing parts. Incorrect

replacement could affect the performance of the

steering system and result in a driving hazard.

2. Handling precautions on srs airbag

system

(A) the vehicle is equipped with srs (supplemental

res ...

Precaution

1. INITIALIZATION

NOTICE:

Perform RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM.

Perform REGISTRATION (VIN registration) when

replacing the ECM.

HINT:

Initialization cannot be completed by only removing the

batt ...

Short to B+ in Driver Side Squib 2nd Step Circuit

DTC B1183/22 Short to B+ in Driver Side Squib 2nd Step Circuit

DESCRIPTION

The driver side squib 2nd step circuit consists of the center airbag sensor

assembly, the spiral cable and

the steering pad.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1183/22 ...