Toyota Sienna Service Manual: Transmission Range Sensor Circuit Malfunction (PRNDL Input)

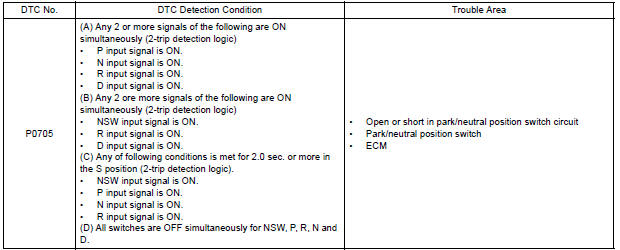

DTC P0705 Transmission Range Sensor Circuit Malfunction (PRNDL Input)

DESCRIPTION

The park/neutral position switch detects the shift lever position and sends signals to the ECM.

HINT: After confirming DTC P0705, use the intelligent tester to confirm the PNP switch signal in the ALL menu (to reach the ALL menu: DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL).

WIRING DIAGRAM

Refer to DTC P0705 for 2WD model or 4WD model.

INSPECTION PROCEDURE

Refer to DTC P0705 for 2WD model or 4WD model.

HINT: Read freeze frame data using the intelligent tester or OBD II scan tool. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was LEAN or RICH, and other data from the time the malfunction occurred.

Actuator Supply Voltage Circuit / Open

Actuator Supply Voltage Circuit / Open

DTC P0657 Actuator Supply Voltage Circuit / Open

DESCRIPTION

The ECM monitors the output voltage to the throttle actuator. This self-check

ensures that the ECM is

functioning properly. The output ...

Throttle Actuator Control Motor Circuit

Throttle Actuator Control Motor Circuit

DTC P2102 Throttle Actuator Control Motor Circuit Low

DTC P2103 Throttle Actuator Control Motor Circuit High

DESCRIPTION

The throttle actuator is operated by the ECM and opens and closes the

thro ...

Other materials:

Automatic Light Control Sensor Circuit

DESCRIPTION

The Multiplex network body ECU receives the signal from the automatic light

control sensor.

HINT:

DTC code is output when malfunction of automatic light control sensor or open or

short of automatic light

control sensor circuit occurs.

WIRING DIAGRAM

INSPECTION PROCEDURE

...

Installation

1. INSTALL ROOF HEADLINING ASSEMBLY

w/ sliding roof:

Install the roof headlining with the 5 clips.

w/o sliding roof:

Install the roof headlining with the 3 clips.

NOTICE:

In order to prevent the roof headlining from

becoming bent, work must be performed by 2 or

more persons when ...

Operation check

1. DETECTION RANGE MEASUREMENT AND INDICATOR CHECK

Turn the IG switch ON.

Move the shift lever to the R position (when the back

sonar and rear clearance sonar is checked).

With front clearance sonar:

Move the shift lever to the N position (when the front

clearance son ...