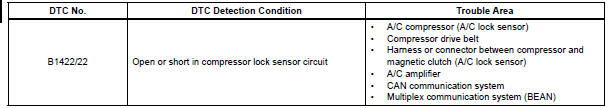

Toyota Sienna Service Manual: Compressor Lock Sensor Circuit

DTC B1422/22 Compressor Lock Sensor Circuit

SYSTEM DESCRIPTION

The ECM sends an engine speed signal to the A/C amplifier via CAN communication and BEAN communication.

The A/C amplifier reads the difference between compressor speed and engine

speed. When the

difference becomes too large, the A/C amplifier determines that the compressor

locks, and turns the

magnetic clutch off.

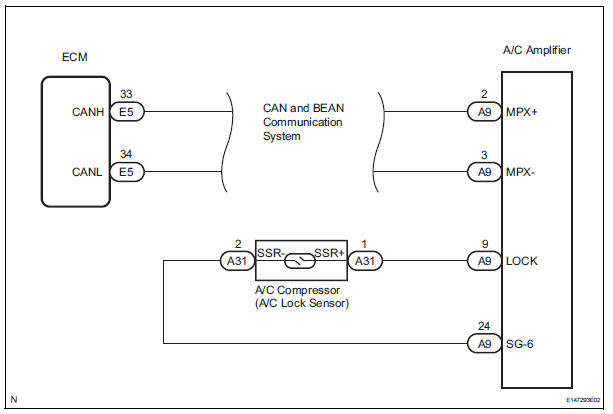

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK CAN COMMUNICATION SYSTEM

(a) Use the intelligent tester to check if the CAN communication system is functioning normally.

Result

2 CHECK MULTIPLEX COMMUNICATION SYSTEM

(a) Use the intelligent tester to check if the multiplex communication system (BEAN) is functioning normally.

Result

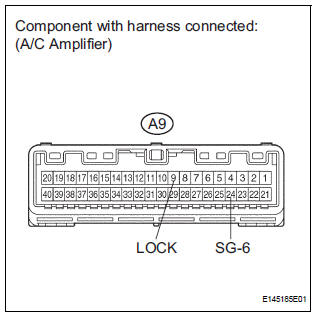

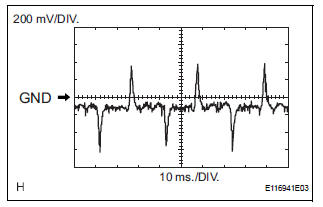

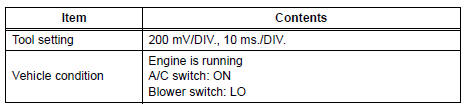

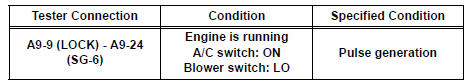

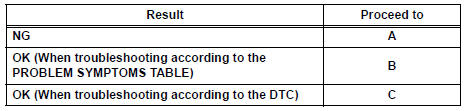

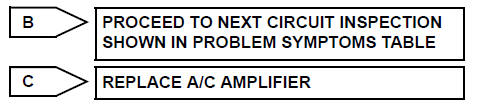

3 INSPECT A/C AMPLIFIER

(a) Remove the A/C amplifier with the connectors still connected.

(b) Measure the waveform of the connector.

Standard

Result

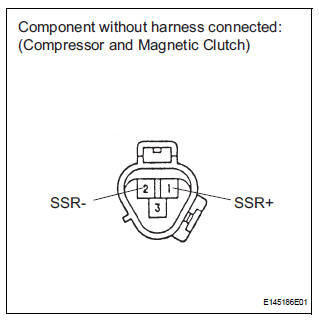

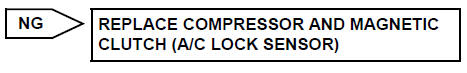

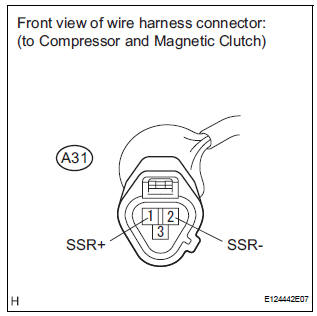

4 INSPECT COMPRESSOR AND MAGNETIC CLUTCH (A/C LOCK SENSOR)

(a) Disconnect the connector from the A/C compressor.

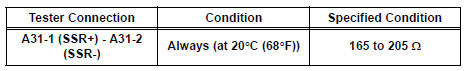

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

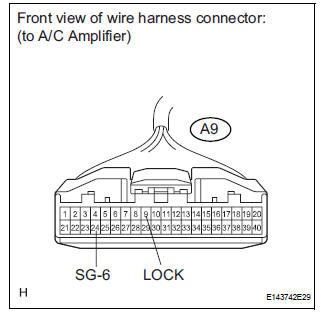

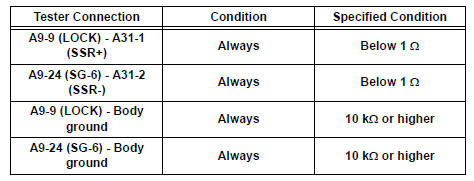

5 CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - A/C LOCK SENSOR)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE A/C AMPLIFIER

Solar Sensor Circuit (Passenger Side)

Solar Sensor Circuit (Passenger Side)

DTC B1421/21 Solar Sensor Circuit (Passenger Side)

DESCRIPTION

The solar sensor, which is installed on the upper side of the instrument

panel, detects sunlight and

controls the air conditioni ...

Pressure Sensor Circuit

Pressure Sensor Circuit

DTC B1423/23 Pressure Sensor Circuit

DESCRIPTION

This DTC is output when refrigerant pressure on the high pressure side is

extremely low (0.19 MPa (2.0

kgf/cm2, 28 psi) or less) or extremely high ...

Other materials:

Noise Occurs from Generator while Engine is Running

INSPECTION PROCEDURE

1 CHECK LOOSENESS OF V-RIBBED BELT

(a) Check the tension of the belt by pushing it down with a

finger.

OK:

The tension of the belt is enough.

2 CHECK V-RIBBED BELT FOR WEAR

(a) Check the V-ribbed belt for wear.

OK:

The V-ribbed belt is not worn.

3 CHECK CLUTC ...

Enter test mode

HINT:

Operation of the tire pressure warning reset switch

can be checked in TEST MODE.

During TEST MODE, the system is not initialized by

pushing the tire pressure warning reset switch. The

circuit of the tire pressure warning reset switch can be

inspected during this mode.

(a) Make ...

Initialization

1. RESET SLIDING ROOF MOTOR

If the AUTO operation function does not operate,

reset the sliding roof motor using any of the

following methods.

Press the sliding roof switch on the TILT UP side

and hold it until the sliding roof motor stops.

Then release the switch and leave it untou ...