Toyota Sienna Service Manual: Disassembly

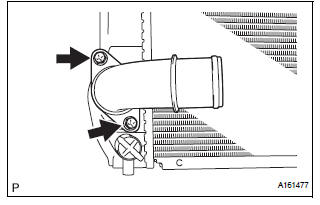

1. REMOVE RADIATOR WATER INLET

(a) Remove the 2 bolts and radiator water inlet.

2. REMOVE DRAIN PLUG

(a) Remove the drain plug and air drain plug.

(b) Remove the 2 O-rings.

3. REMOVE LOWER RADIATOR TANK

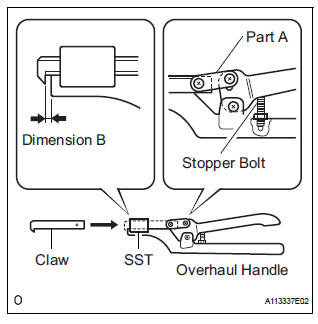

(a) Install the claw to the overhaul handle, inserting it in the hole in Part A as shown in the illustration.

SST 09230-01010 (09231-01010, 09231-01030) (b) While squeezing the handle, adjust the stopper bolt so that dimension B is as specified below.

Dimension B: 0.2 to 0.3 mm (0.008 to 0.012 in.)

| NOTICE: If the stopper bolt is not adjusted, the claw may be damaged. |

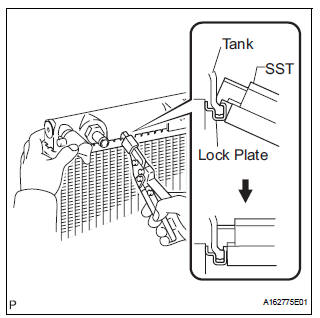

(c) Using SST, uncrimp the lock plate by squeezing the handle until stopped by the stopper bolt.

SST 09230-01010

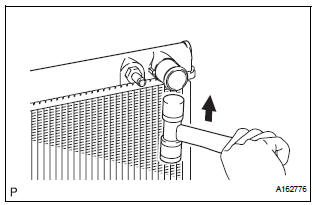

(d) Lightly tap the bracket of the radiator (or radiator hose inlet or outlet) with a soft-faced hammer and remove the tank.

(e) Remove the O-ring.

4. REMOVE UPPER RADIATOR TANK

HINT: The removal procedure for the upper radiator tank is the same as that for the lower radiator tank.

Removal

Removal

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

2 ...

Inspection

Inspection

1. INSPECT LOCK PLATE FOR DAMAGE

(a) Inspect the lock plate for damage.

HINT:

Reassembly of a deformed tank will be

impossible. Therefore, first correct the shape of

the lock plate groov ...

Other materials:

Removal

1. REMOVE FRONT WIPER ARM HEAD CAP

Using a small screwdriver, remove the 2 front wiper

arm covers.

HINT:

Tape up the screwdriver tip before use.

2. REMOVE FR WIPER ARM RH

Operate the wiper, and stop the windshield wiper

motor assembly to the automatic stop position.

...

Open in Pump Motor Circuit

DTC C1251/51 Open in Pump Motor Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ABS MOTOR RELAY)

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine.

(c) Select the ACTIVE TEST mode on the intelligent tester.

...

Installation

1. REMOVE FRONT SEAT INNER BELT ASSEMBLY

HINT:

Refer to the instructions for reassembly of the front

seat assembly (for flat type).

Refer to the instructions for reassembly of the front

seat assembly (for manual seat).

Refer to the instructions for reassembly of the fr ...