Toyota Sienna Service Manual: Disassembly

1. INSPECT OIL PUMP ASSEMBLY

HINT: (See page AX-234)

2. REMOVE CLUTCH DRUM OIL SEAL RING

(a) Remove the 2 clutch drum oil seal rings.

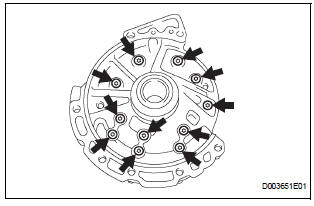

3. REMOVE STATOR SHAFT ASSEMBLY

(a) Using a "torx" socket (T30), remove the 11 bolts and stator shaft.

4. INSPECT CLEARANCE OF OIL PUMP ASSEMBLY

HINT: (See page AX-234)

5. REMOVE FRONT OIL PUMP DRIVE GEAR

(a) Remove the front oil pump drive gear.

6. REMOVE FRONT OIL PUMP DRIVEN GEAR

(a) Remove the front oil pump driven gear.

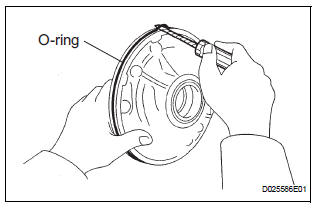

7. REMOVE FRONT OIL PUMP BODY O-RING

(a) Using a screwdriver, remove the O-ring.

HINT: Tape the screwdriver before use.

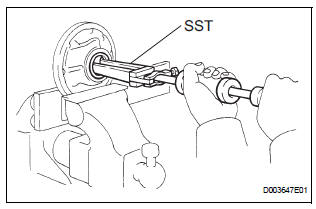

8. REMOVE FRONT OIL PUMP OIL SEAL

(a) Mount the oil pump in a soft jaw vise.

(b) Using SST, remove the oil seal from the oil pump body.

SST 09308-00010

Oil pump

Oil pump

COMPONENTS

...

Inspection

Inspection

1. INSPECT OIL PUMP ASSEMBLY

(a) Turn the drive gear with the 2 screwdrivers and

make sure that it rotates smoothly.

NOTICE:

Be careful not to damage the oil seal lip.

2. INSPEC ...

Other materials:

Removal

1. REMOVE BACK DOOR CENTER GARNISH (See page

ET-18)

2. REMOVE POWER BACK DOOR ROD (See page ED-

220)

3. REMOVE BACK DOOR LH SIDE GARNISH

4. REMOVE BACK DOOR RH SIDE GARNISH

5. REMOVE BACK DOOR PULL STRAP (See page ED-

221)

6. REMOVE BACK DOOR TRIM BOARD ASSEMBLY

7. REMOVE LH BACK-UP LIGH ...

Scratched / Reversed Disc

DTC 62-46 Scratched / Reversed Disc

DTC 63-46 Scratched / Reversed Disc

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

62-46

Scratches or dirt is found on CD surface or CD is set

upside down.

CD

Radio receiver

...

Precaution

1. GENERAL PRECAUTION

When using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

PARTS LOCATION

SYSTEM DIAGRAM

1. SIGNAL COMMUNICATION TABLE

Driver Side Power Seat (w ...