Toyota Sienna Service Manual: Disassembly

1. REMOVE PROPELLER SHAFT ASSEMBLY

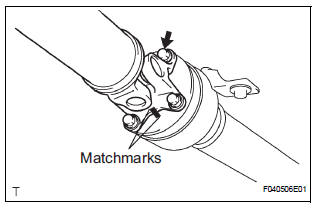

(a) Put matchmarks on both the flanges.

(b) Remove the 4 nuts, bolts and washers.

2. REMOVE INTERMEDIATE SHAFT

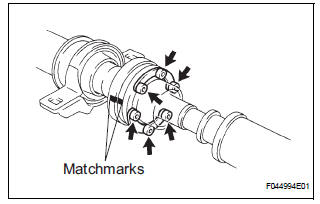

(a) Put matchmarks on the propeller shaft subassembly and universal joint flange.

NOTICE: Do not use a punch for the marks.

(b) Using a hexagon wrench (6 mm), remove the 6 bolts and 2 washers and separate the intermediate shaft from the propeller shaft assembly rear.

3. REMOVE CENTER SUPPORT BEARING ASSEMBLY NO.1

(a) Using a chisel and a hammer, loosen the staked part of the nut.

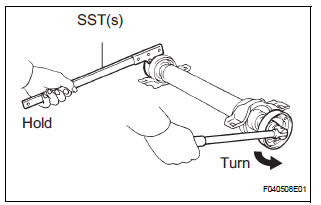

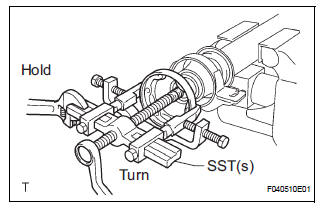

(b) Using SST(s) to hold the front flange, remove the nut and plate washer.

SST 09330-00021

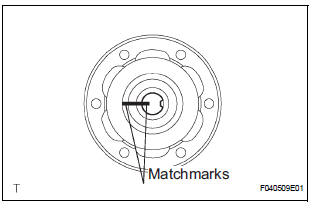

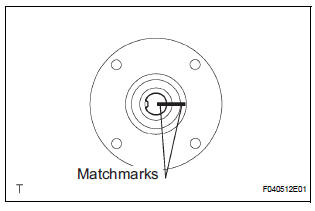

(c) Put matchmarks on the rear flange and shaft.

(d) Hold the intermediate shaft in a vise between aluminium plates.

NOTICE: Do not overtighten the vise

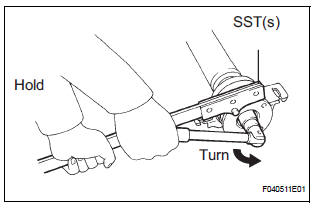

(e) Using SST(s), remove the rear flange.

SST 09950-40011 (09951-04020, 09952-04010, 09953-04030, 09954-04010, 09955-04061, 09957-04010, 09958-04011)

NOTICE: Be careful not to damage the universal joint flange.

(f) Remove the center support bearing assembly No. 1 (rear) and washer.

4. REMOVE CENTER SUPPORT BEARING ASSEMBLY NO.1

(a) Using a chisel and a hammer, loosen the staked part of the nut.

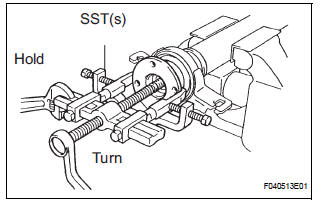

(b) Using SST(s) to hold the front flange, remove the nut and plate washer.

SST 09330-00021

(c) Put matchmarks on the front flange and shaft.

(d) Hold the intermediate shaft in a vise between aluminium plates.

NOTICE: Do not overtighten the vise.

(e) Using SST(s), remove the front flange.

SST 09950-40011 (09951-04020, 09952-04010, 09953-04030, 09954-04010, 09955-04061, 09957-04010, 09958-04011)

NOTICE: Be careful not to damage the universal joint flange.

(f) Remove the center support bearing assembly No. 1 (front) and washer.

Removal

Removal

1. REMOVE EXHAUST PIPE ASSEMBLY

(a) Remove exhaust pipe assembly (See page EX-8).

2. REMOVE PROPELLER W/CENTER BEARING SHAFT ASSEMBLY

(a) Depress the brake pedal and hold it down.

(b) Using ...

Inspection

Inspection

1. INSPECT SPIDER BEARING

(a) Check that the spider bearing moves smoothly by

turning the flange.

(b) Check for the looseness around the joint by strongly

moving the flange in the axial and ...

Other materials:

MIL Circuit

DESCRIPTION

The MIL (Malfunction Indicator Lamp) is used to indicate vehicle malfunctions

detected by the ECM.

When the ignition switch is turned to the ON position, power is supplied to the

MIL circuit, and the ECM

provides the circuit ground which illuminates the MIL.

The MIL operation ...

DTC check / clear

1. CHECK DTC

Connect the intelligent tester to the DLC3.

Connect the intelligent tester to the Controller

Area Network Vehicle Interface Module (CAN

VIM). Then connect the CAN VIM to the Data

Link Connector 3 (DLC3).

Turn the ignition switch to the ON posi ...

Adjustment

HINT:

If the malfunction does not disappear by following the

procedure in ADJUSTMENT and the rear No. 2 seat

assembly needs to be replaced, do not disassemble the rear

No. 2 seat assembly.

1. ADJUST FRONT LEG

HINT:

Perform the following procedure if the inner leg does not

lock.

P ...