Toyota Sienna Service Manual: Drive belt

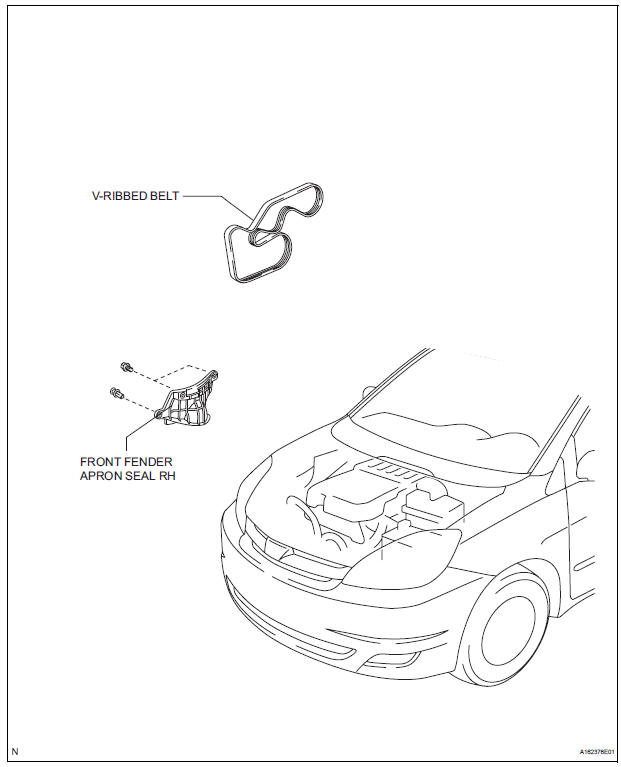

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See page EM-26)

3. REMOVE V-RIBBED BELT

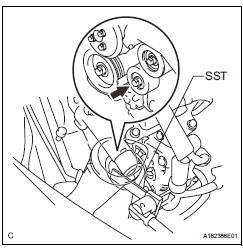

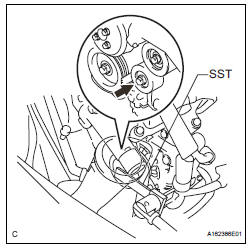

(a) Using SST, release the belt tension by turning the belt tensioner counterclockwise, and remove the Vribbed belt from the belt tensioner.

SST 09249-63010

(b) While turning the belt tensioner counterclockwise, align with its holes, and then insert the 5 mm bihexagon wrench into the holes to fix the V-ribbed belt tensioner.

INSPECTION

1. INSPECT V-RIBBED BELT

(a) Visually check the V-ribbed belt for excessive wear, frayed cords, etc.

If any defect has been found, replace the V-ribbed belt.

HINT:

Cracks on the rib side of a V-ribbed belt are considered acceptable.

If the drive belt has chunks missing from its ribs, it should be replaced.

HINT:

- A "new belt" is a belt which has been used for less than 5 minutes with the engine running.

- A "used belt" is a belt which has been used for 5 minutes or more with the engine running.

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the tensioner by turning it clockwise and counterclockwise.

If a malfunction exitsts, replace the tensioner.

INSTALLATION

1. INSTALL V-RIBBED BELT

(a) Install the V-ribbed belt.

(b) Using SST, turn the belt tensioner counterclockwise and remove the bar.

SST 09249-63010

(c) If it is difficult to install the V-ribbed belt, perform the following procedure:

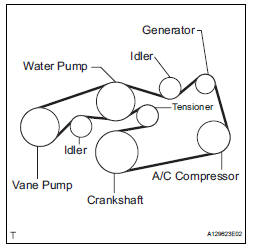

(1) Put the V-ribbed belt on every pulley except the tensioner pulley as shown in the illustration.

(2) While releasing the belt tension by turning the belt tensioner counterclockwise, put the Vribbed belt on the tensioner pulley.

NOTICE:

|

(3) After installing the V-ribbed belt, check that it fits properly in the ribbed grooves. Confirm that the belt has not slipped out of the grooves on the bottom of the crank pulley by hand.

2. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62) 3. INSTALL FRONT WHEEL RH Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

Engine

Engine

ON-VEHICLE INSPECTION

1. INSPECT ENGINE COOLANT

(a) Inspect the engine coolant (See page CO-1).

2. INSPECT ENGINE OIL

(a) Inspect the engine oil (See page LU-1).

3. INSPECT BATTERY

(a) Inspect t ...

Engine front oil seal

Engine front oil seal

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

3. REMOVE V-RIBBED BELT (See page EM-6)

4. REMOVE CRANKSHAFT PULLEY

(a) Using SST, loos ...

Other materials:

Intake Air Temperature Sensor Gradient Too

High

DTC P0111 Intake Air Temperature Sensor Gradient Too

High

DESCRIPTION

The Intake Air Temperature (IAT) sensor, mounted on the Mass Air Flow (MAF)

meter, monitors the IAT.

The IAT sensor has a built-in thermistor with a resistance that varies according

to the temperature of the

intake ...

Short in Side Squib LH Circuit

DTC B0115/47 Short in Side Squib LH Circuit

DESCRIPTION

The side squib LH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0115/47 is recorded when a short ci ...

On-vehicle inspection

1. INSPECT CURTAIN SHIELD AIRBAG ASSEMBLY

(VEHICLE NOT INVOLVED IN COLLISION)

Perform a diagnostic system check.

With the curtain shield airbag assembly installed on

the vehicle, perform a visual check. If there are any

defects as mentioned below, replace the front pillar

...