Toyota Sienna Service Manual: Engine coolant temperature sensor

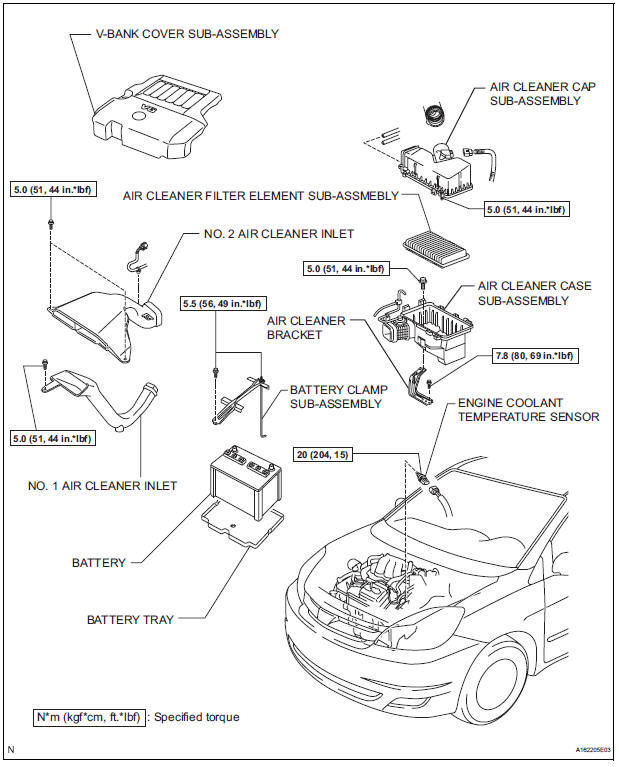

COMPONENTS

REMOVAL

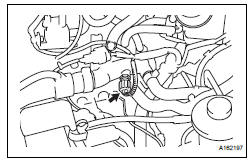

1. DRAIN ENGINE COOLANT (See page CO-6) 2. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28) 3. REMOVE NO. 2 AIR CLEANER INLET (See page EM- 28) 4. REMOVE NO. 1 AIR CLEANER INLET (See page EM- 28) 5. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page ES-493) 6. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See page EM-28) 7. REMOVE ENGINE COOLANT TEMPERATURE SENSOR

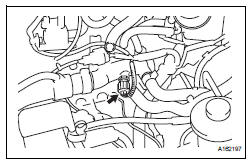

(a) Remove the engine coolant temperature sensor connector.

(b) Remove the engine coolant temperature sensor.

INSPECTION

1. INSPECT ENGINE COOLANT TEMPERATURE SENSOR

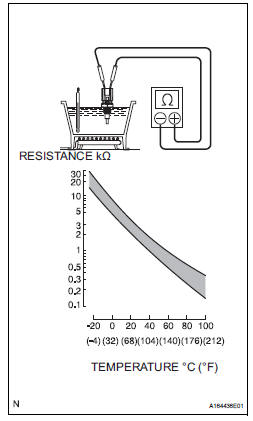

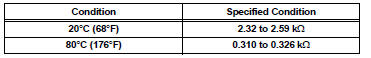

(a) Using an ohmmeter, measure the resistance between the terminals.

Standard resistance

- If the result is as specified, do not replace the engine coolant temperature sensor

- If the result is not as specified, replace the engine coolant temperature sensor.

| NOTICE: In case of checking the engine coolant temperature sensor in water, do not allow water to go into the terminals. After checking, dry the engine coolant temperature sensor. |

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

(a) Install the engine coolant temperature sensor.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf) (b) Connect the engine coolant temperature sensor connector.

2. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See page EM-59) 3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See page ES-496) 4. INSTALL NO. 1 AIR CLEANER INLET (See page EM- 59) 5. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60) 6. ADD ENGINE COOLANT (See page CO-7) 7. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1) 8. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63)

Crankshaft position sensor

Crankshaft position sensor

Components

Removal

1. Remove compressor and magnetic clutch

HINT:

(See page AC-227 )

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor

connector.

(b) R ...

Knock sensor

Knock sensor

COMPONENTS

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIE ...

Other materials:

Noise Occurs from Generator while Engine is Running

INSPECTION PROCEDURE

1 CHECK LOOSENESS OF V-RIBBED BELT

(a) Check the tension of the belt by pushing it down with a

finger.

OK:

The tension of the belt is enough.

2 CHECK V-RIBBED BELT FOR WEAR

(a) Check the V-ribbed belt for wear.

OK:

The V-ribbed belt is not worn.

3 CHECK CLUTC ...

Inspection

1. INSPECT STEERING PAD SWITCH LH (w/o

Navigation System)

Measure the resistance according to the values in

the table below.

Standard resistan

If the result is not as specified, replace the steering

pad switch LH.

2. INSPECT STEERING PAD SWITCH RH (w/ Navigation

System)

...

Selecting, fast-forwarding and reversing tracks/files/songs

Selecting a track/file/song

Press the ‚Äú‚ÄĚ or ‚Äú‚ÄĚ button on ‚ÄúSEEK‚ÄĘTRACK‚ÄĚ or turn the

‚ÄúTUNE‚ÄĘSCROLL‚ÄĚ knob to select the desired track/file/song number.

To fast-forward or reverse, press and hold the ‚Äú‚ÄĚ or ‚Äú‚ÄĚ button on

‚ÄúSEEK‚ÄĘTRACK‚ÄĚ.

...