Toyota Sienna Service Manual: Engine front oil seal

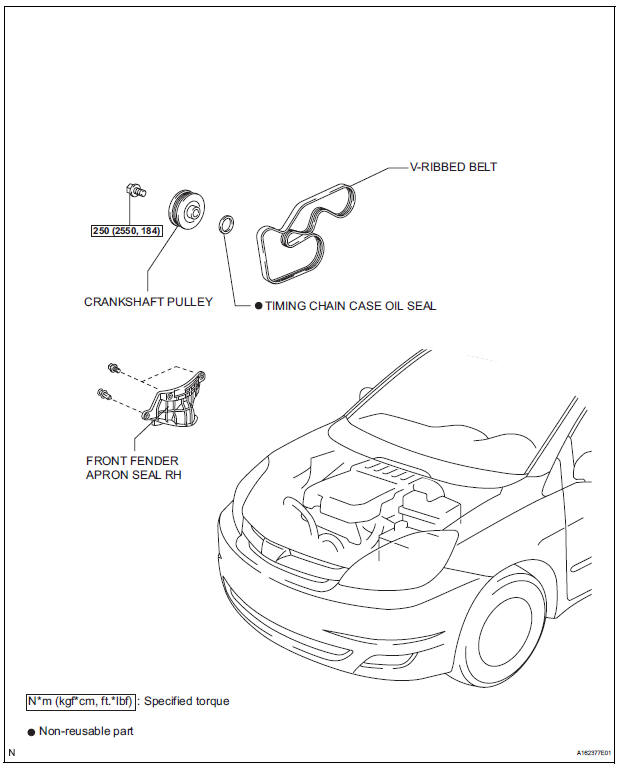

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH 2. REMOVE FRONT FENDER APRON SEAL RH (See page EM-26) 3. REMOVE V-RIBBED BELT (See page EM-6) 4. REMOVE CRANKSHAFT PULLEY

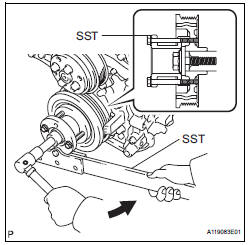

(a) Using SST, loosen the crankshaft pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

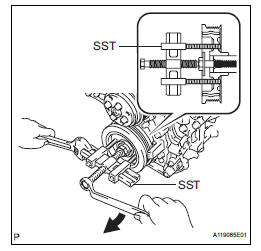

(b) Using SST, remove the crankshaft pulley bolt and crankshaft pulley.

SST 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021)

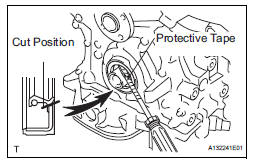

5. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

| NOTICE: After the removal, check the crankshaft for damage. If it is damaged, smooth the surface with 400-grit sandpaper. |

INSTALLATION

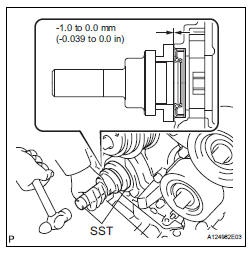

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Apply MP grease to a new oil seal lip.

(b) Using SST and a hammer, tap in the oil seal until its surface is flush with the timing chain cover edge.

SST 09223-22010, 09506-35010

NOTICE:

|

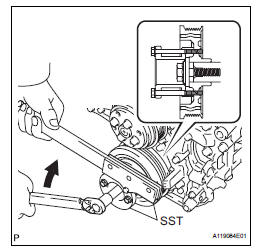

2. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021 Torque: 250 N*m (2550 kgf*cm, 184 ft.*lbf)

3. INSTALL V-RIBBED BELT (See page EM-7) 4. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62) 5. INSTALL FRONT WHEEL RH Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

Drive belt

Drive belt

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

3. REMOVE V-RIBBED BELT

(a) Using SST, release the belt tension by turning the

belt tensi ...

Engine rear oil seal

Engine rear oil seal

Components

Removal

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

2WD)

HINT:

See page AX-163.

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

4WD)

HINT:

See page AX-167.

3. REMOVE DRIVE PLATE A ...

Other materials:

Removal

1. PRECAUTION

CAUTION:

Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE INSTRUMENT PANEL FINISH PANEL SUBASSEMBLY LOWER L ...

Air conditioning controls

Adjusting the temperature setting

Turn the “TEMP” dial clockwise to increase the temperature and

counterclockwise to decrease the temperature.

The “SYNC” button

The air conditioning system switches between individual (indicator(

s) off) and simultaneous (indicators on) modes.

Whe ...

Removal

NOTICE:

Do not adjust the brake booster push rod.

Do not change the combination of the diameter

converting unit and brake.

1. DRAIN BRAKE FLUID

NOTICE:

Wash the brake fluid off immediately if it attaches to

any painted surfaces.

2. SEPARATE BATTERY NEGATIVE TERMINAL

3. REMOVE AIR CLE ...