Toyota Sienna Service Manual: Inspection

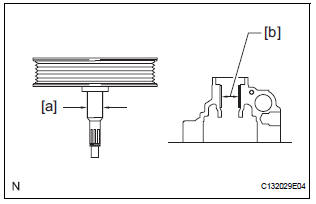

1. INSPECT VANE PUMP SHAFT AND BUSHING IN VANE PUMP FRONT HOUSING

(a) Using a micrometer, measure the outer diameter [a] of the vane pump shaft with pulley.

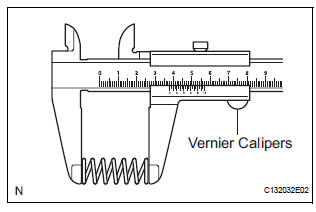

(b) Using vernier calipers, measure the inner diameter [b] of the vane pump front housing bushing.

(c) Calculate the oil clearance.

Oil clearance = Inner diameter of the bushing [b] - Outer diameter of the shaft [a]

Maximum oil clearance: 0.07 mm (0.0028 in.)

If the oil clearance exceeds the maximum, replace the vane pump assembly.

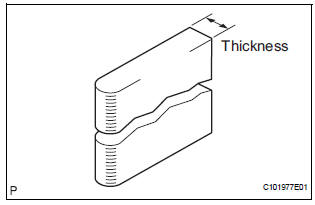

2. INSPECT VANE PUMP ROTOR AND VANE PUMP PLATE CLEARANCE

(a) Using a micrometer, measure the thickness of the vane pump plates.

Standard thickness: 1.405 to 1.411 mm (0.05531 to 0.05555 in.) If the thickness is not within the specified range, replace the vane pump assembly.

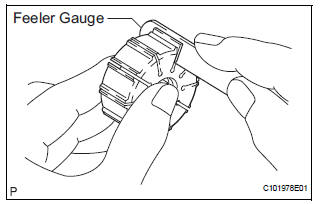

(b) Using a feeler gauge, measure the clearance between the side face of the vane pump rotor groove and the vane pump plates.

Maximum clearance: 0.03 mm (0.0012 in.) If the clearance exceeds the maximum, replace the vane pump assembly.

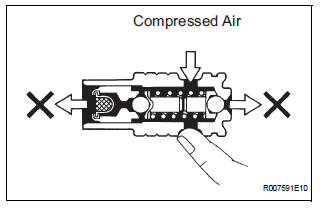

3. INSPECT FLOW CONTROL VALVE ASSEMBLY

(a) Coat the flow control valve assembly with power steering fluid and check that it falls smoothly into the flow control valve due to its own weight.

If the control valve does not fall into the hole smoothly, replace the vane pump assembly.

(b) Check the flow control valve assembly for leaks.

Close one of the holes and apply compressed air, 392 to 490 kPa (4 to 5 kgf/cm2, 57 to 71 psi), into the opposite side hole, and confirm that air does not come out from the holes in the ends of the flow control valve assembly.

If air leaks, replace the vane pump assembly.

4. INSPECT FLOW CONTROL VALVE COMPRESSION SPRING

(a) Using vernier calipers, measure the free length of the flow control valve compression spring.

Minimum free length: 29.2 mm (1.150 in.) If the length is less than the minimum, replace the vane pump assembly

5. INSPECT PRESSURE PORT UNION

If the union seat in the pressure port union is severely damaged, replace the vane pump assembly.

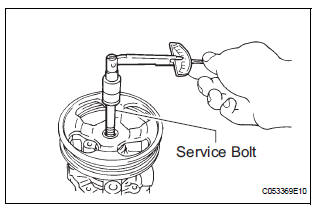

6. INSPECT TOTAL PRELOAD

(a) Check that the pump rotates smoothly without abnormal noise.

(b) Temporarily install the service bolt.

Recommended service bolt: Thread diameter: 10 mm (0.39 in.) Thread pitch: 1.25 mm (0.0492 in.) Bolt length: 50 mm (1.97 in.)

(c) Using a torque wrench, check the pump rotating torque.

Rotating torque: 0.27 N*m (2.8 kgf*cm, 2.4 in.*lbf) or less

If the rotating torque is not as specified, check the vane pump housing oil seal.

Disassembly

Disassembly

1. HOLD VANE PUMP ASSEMBLY

(a) Using SST, hold the vane pump assembly in a vise.

SST 09630-00014 (09631-00132)

2. REMOVE POWER STEERING SUCTION PORT UNION

(a) Remove the bolt and the pow ...

Reassembly

Reassembly

NOTICE:

Before installation, coat the parts indicated by arrows

with power steering fluid (See page PS-7).

1. INSTALL VANE PUMP HOUSING OIL SEAL

(a) Coat a new vane pump housing oil seal lip with

...

Other materials:

Short to B+ in Rear Curtain Shield Squib LH

Circuit

DTC B1638/86 Short to B+ in Rear Curtain Shield Squib LH

Circuit

DESCRIPTION

The rear curtain shield squib LH circuit consists of the center airbag sensor

assembly and the curtain

shield airbag assembly LH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B ...

All Doors cannot be Locked / Unlocked at Once

DESCRIPTION

The body ECU receives a switch signal from the master switch, the door

control switch, the driver door

key cylinder and the passenger door key cylinder and then drives the door lock

motor.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT FUSE (ECU-B)

Remove ECU-B fuse f ...

Inspection

1. INSPECT STEERING PAD SWITCH LH (w/o

Navigation System)

Measure the resistance according to the values in

the table below.

Standard resistan

If the result is not as specified, replace the steering

pad switch LH.

2. INSPECT STEERING PAD SWITCH RH (w/ Navigation

System)

...