Toyota Sienna Service Manual: Inspection

1. Inspect pack clearance of reverse clutch

(A) install the intermediate shaft and needle roller bearing onto the transaxle rear cover.

(B) using a dial indicator, measure the reverse clutch pack clearance while applying and releasing compressed air (392 kpa, 4.0 Kgf/cm2, 57 psi).

Pack clearance: 0.60 To 0.82 Mm (0.02362 To 0.03228 In.)V

If the pack clearance is not as specified, inspect the discs, plates and flange.

2. Inspect pack clearance of direct clutch and overdrive clutch

(a) Using a dial indicator, measure the direct clutch and overdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

Pack clearance: 0.61 to 0.83 mm (0.02401 to 0.03268 in.)

If the pack clearance is not as specified, inspect the discs, plates and flange.

3. INSPECT DIRECT MULTIPLE DISC CLUTCH DISC

(a) Check if the sliding surfaces of the disc, plate and flange are worn or burnt.

If necessary, replace them.

HINT:

- If the lining of the disc comes off or discolors, or if a part of the groove is worn, replace all discs.

- Before installing new discs, immerse them in ATF for at least 15 minutes.

4. INSPECT OVERDRIVE DIRECT CLUTCH DISC

(a) Check if the sliding surface of the disc, plate and flange are worn or burnt.

If necessary, replace them.

HINT:

- If the lining of the disc comes off or discolors, or if a part of the groove is worn, replace all discs

- Before installing new discs, immerse them in ATF for at least 15 minutes.

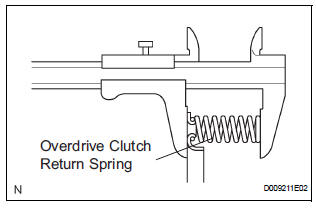

5. INSPECT OVERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Using vernier calipers, measure the free length of the spring together with the spring seat.

Standard free length: 25.91 mm (1.0201 in.)

6. INSPECT PACK CLEARANCE OF REVERSE CLUTCH

(a) Install the intermediate shaft onto the transaxle rear cover.

(b) Using a dial indicator, measure the direct clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

Clearance: 0.60 to 0.82 mm (0.02362 to 0.03228 in.)

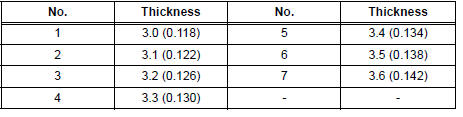

If the pack clearance is less than the minimum, parts may have been assembled incorrectly, so check and reassemble again. If the clearance is not as specified, select another flange.

HINT: There are 7 flanges of different thickness.

Flange thickness: mm (in.)

7. INSPECT PACK CLEARANCE OF DIRECT CLUTCH AND OVERDRIVE CLUTCH

(a) Using a dial indicator, measure the direct clutch & overdrive clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

psi).

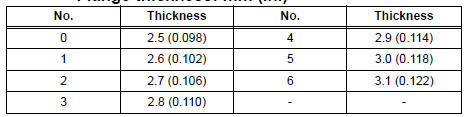

Clearance: 0.61 to 0.83 mm (0.02401 to 0.03268 in.)

If the pack clearance is less than the minimum, parts may have been assembled incorrectly, so check and reassemble again. If the clearance is not as specified, select another flange.

HINT: There are 7different thicknesses of flanges available

Flange thickness: mm (in.)

(b) Check that the disc rotates when rotating the disc after inserting the rear planetary sun gear.

NOTICE: Do not place the rear planetary sun gear in a vise.

Disassembly

Disassembly

1. INSPECT PACK CLEARANCE OF REVERSE CLUTCH

HINT:

(See page AX-249)

2. INSPECT PACK CLEARANCE OF DIRECT CLUTCH

AND OVERDRIVE CLUTCH

HINT:

(See page AX-249)

3. REMOVE DIRECT MULTIPLE DISC CLUTCH ...

Reassembly

Reassembly

1. INSTALL OVERDRIVE DIRECT CLUTCH O-RING

(a) Coat an O-ring with ATF, and install it to the direct

clutch drum.

NOTICE:

Make sure that the O-ring is not twisted or

pinched when it is install ...

Other materials:

Engine unit

COMPONENTS

...

Window glass antenna wire

INSPECTION

1. INSPECT WINDOW GLASS ANTENNA WIRE

Inspect the wind glass antenna wire.

NOTICE:

When cleaning the glass, use a soft, dry cloth,

and wipe the glass in the direction of the wire.

Take care not to damage the wires. Do not use

detergents or glass cleaners with abrasiv ...

Throttle / Pedal Position Sensor / Switch "D"

Circuit Range / Performance

DTC P2121 Throttle / Pedal Position Sensor / Switch "D"

Circuit Range / Performance

HINT:

This DTC relates to the Accelerator Pedal Position (APP) sensor.

DESCRIPTION

Refer to DTC P2120

MONITOR DESCRIPTION

The accelerator pedal position sensor is mounted on the accelerator pedal ...