Toyota Sienna Service Manual: Installation

1. INSTALL FRONT SHOCK ABSORBER WITH COIL SPRING

(a) Install the front shock absorber with coil spring as shown in the illustration.

(b) Install the 3 nuts to the upper side of the front shock absorber with coil spring.

Torque: 80 N*m (816 kgf*cm, 59 ft.*lbf)

(c) Install the 2 bolts and 2 nuts to the lower side of the front shock absorber with coil spring.

Torque: 210 N*m (2,140 kgf*cm, 155 ft.*lbf)

NOTICE: When installing the bolt, hold the nut not to rotate.

(d) Fully tighten the lock nut.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

(e) Install the front flexible hose No.1 and speed sensor front LH with the bolt.

Torque: 19 N*m (189 kgf*cm, 14 ft.*lbf)

2. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(a) Install the front stabilizer link assembly LH with the nut.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

HINT: If the ball joint turns together with the nut, use a hexagon (6 mm) wrench to hold the stud.

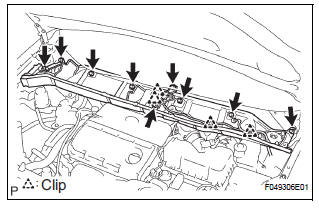

3. INSTALL COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT

(a) Install the cowl top brace and cowl top panel subassembly outer front with the 9 bolts.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf) (b) Connect the wire harness to the cowl top panel subassembly outer front.

4. INSTALL WINDSHIELD WIPER MOTOR & LINK ASSEMBLY

HINT: (See page WW-3)

5. INSTALL FR WIPER ARM LH

HINT: (See page WW-3)

6. INSTALL FR WIPER ARM RH

HINT: (See page WW-3)

7. INSTALL FRONT WHEEL Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

8. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT: (See page SP-4)

Reassembly

Reassembly

1. INSTALL SHOCK ABSORBER ASSEMBLY FRONT LH

2. INSTALL FRONT COIL SPRING INSULATOR LOWER

LH

(a) Install the front coil spring insulator lower LH onto

the shock absorber assembly front LH.

3. INST ...

Disposal

Disposal

1. DISPOSE OF SHOCK ABSORBER ASSEMBLY FRONT LH

HINT:

Dispose the RH side by the same procedures as the LH

side.

(a) Fully extend the shock absorber rod.

(b) Using a drill, make a hole in the cy ...

Other materials:

Jam Protection Function Activates During Power Slide Door RH

Operation

DESCRIPTION

It may be caused by ill-fitting slide door, faulty touch sensor or

faulty pulse sensor.

The power slide door ECU activates the slide motor to open / close

the power slide door, thus

controlling the power slide door operation. For jam and foreign object

detect ...

Open in Front Pretensioner Squib LH Circuit

DTC B0136/74 Open in Front Pretensioner Squib LH Circuit

DESCRIPTION

The front pretensioner squib LH circuit consists of the center airbag sensor

assembly and the front seat

outer belt assembly LH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0136/74 i ...

Inspection

1. INSPECT OIL PUMP ASSEMBLY

(a) Turn the drive gear with the 2 screwdrivers and

make sure that it rotates smoothly.

NOTICE:

Be careful not to damage the oil seal lip.

2. INSPECT CLEARANCE OF OIL PUMP ASSEMBLY

(a) Push the driven gear to one side of the body.

(b) Using ...