Toyota Sienna Service Manual: Installation

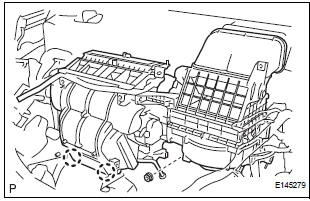

1. TEMPORARILY TIGHTEN AIR CONDITIONING UNIT ASSEMBLY

(a) Engage the 2 claws.

(b) Temporarily tighten the air conditioning unit assembly with the nut.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

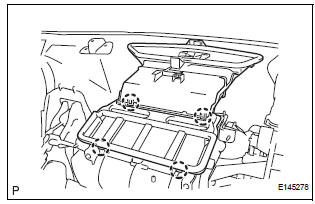

2. INSTALL LOWER DEFROSTER NOZZLE ASSEMBLY

(a) Engage the 4 claws and install the lower defroster nozzle assembly.

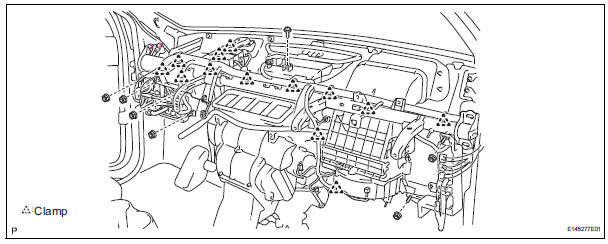

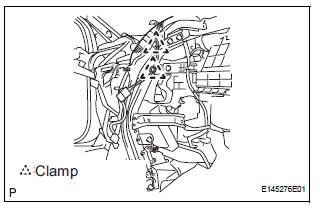

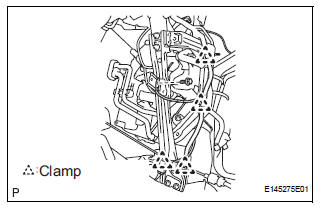

3. INSTALL INSTRUMENT PANEL REINFORCEMENT

(a) Install the instrument panel reinforcement with the 10 bolts.

(b) Install the 13 clamps.

(c) Connect the connectors.

(d) Install the screw.

(e) Install the 6 nuts.

Torque: 7.3 N*m (74 kgf*cm, 65 in.*lbf)

4. INSTALL AIR CONDITIONING UNIT ASSEMBLY

(a) Install the air conditioner unit assembly with the 3 bolts and 2 nuts.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

5. INSTALL FRONT FENDER GARNISH RH

6. INSTALL ECM (See page ES-499)

7. INSTALL STEREO COMPONENT AMPLIFIER ASSEMBLY (w/ Stereo Component Amplifier) (See page AV-173)

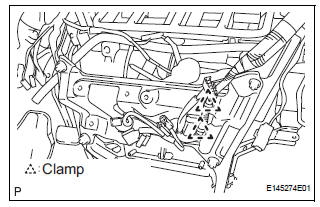

8. INSTALL NO. 2 INSTRUMENT PANEL BRACE SUBASSEMBLY

(a) Install the No. 2 instrument panel brace subassembly with the 3 bolts and 2 nuts.

(b) Engage the 2 clamps.

(c) Connect the connector.

9. INSTALL NO. 1 INSTRUMENT PANEL BRACE SUBASSEMBLY

(a) Install the No. 1 instrument panel brace subassembly with the 3 bolts and 2 nuts.

(b) Engage the 4 clamps.

(c) Install the bolt.

(d) Connect the connector.

10. INSTALL NO. 5 INSTRUMENT PANEL BRACKET

(a) Install the No. 5 instrument panel bracket with the 4 nuts.

(b) Engage the 2 clamps.

(c) Connect the connector.

11. INSTALL SHIFT LEVER ASSEMBLY

HINT: (See page AX-150 for U151E, AX-150 for U151F)

12. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

HINT: (See page AX-156 for U151E, AX-156 for U151F)

13. INSTALL STEERING COLUMN ASSEMBLY (See page SR-10)

14. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY (See page SR-10)

15. INSTALL NO. 1 HEATER TO FOOT DUCT

(a) Install the No. 1 heater to foot duct with the clip.

16. INSTALL NO. 3 HEATER TO FOOT DUCT

(a) Install the No. 3 heater to foot duct with the clip.

17. INSTALL SPIRAL CABLE (See page RS-434)

18. INSTALL INSTRUMENT PANEL ASSEMBLY WITH PASSENGER AIRBAG ASSEMBLY

HINT: (See page IP-14)

19. INSTALL HEATER WATER INLET HOSE A

20. CONNECT HEATER WATER OUTLET HOSE A (FROM HEATER UNIT)

(a) Using pliers, grip the claws of the clip and slide the clip to connect the heater water outlet hose A (from heater unit).

21. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See page IT-5)

22. INSTALL SUCTION HOSE SUB-ASSEMBLY

(a) Lubricate a new O-ring with compressor oil and install it on the hose.

Compressor oil: ND-OIL 8 or equivalent

(b) Install the suction hose sub-assembly and the piping clamp.

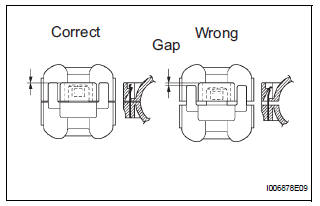

HINT: After the connection, check the claw fitting of the piping clamp.

23. INSTALL COOLER REFRIGERANT LIQUID PIPE E (TO COOLER UNIT)

(a) Lubricate a new O-ring with compressor oil and install it to the pipe.

Compressor oil: ND-OIL 8 or equivalent

(b) Install the cooler refrigerant liquid pipe E and the piping clamp.

HINT: After the connection, check the claw fitting of the piping clamp.

24. INSTALL FRONT COWL TOP OUTER PANEL SUBASSEMBLY (See page SP-18)

25. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (See page WW-6)

26. INSTALL COWL TOP VENTILATOR LOUVER SUBASSEMBLY (See page WW-6)

27. INSTALL FRONT WIPER ARM LH (See page WW-6)

28. INSTALL FRONT WIPER ARM RH (See page WW-7)

29. INSTALL FRONT WIPER ARM HEAD CAP (See page WW-7)

30. ADJUST SHIFT LEVER POSITION

HINT: (See page AX-149 for U151E, AX-149 for U151F)

31. INSPECT SHIFT LEVER POSITION

HINT: (See page AX-152 for U151E, AX-152 for U151F)

32. INSPECT KEY INTERLOCK OPERATION

HINT: (See page AX-152 for U151E, AX-152 for U151F)

33. INSPECT SHIFT LOCK OPERATION

HINT: (See page AX-152 for U151E, AX-152 for U151F)

34. INSPECT SHIFT LOCK RELEASE BUTTON OPERATION

HINT: (See page AX-152 for U151E, AX-152 for U151F)

35. ADD ENGINE COOLANT (See page CO-7)

36. CHARGE WITH REFRIGERANT (See page AC-173)

37. WARM UP ENGINE

38. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1)

39. INSPECT FOR REFRIGERANT LEAK (See page AC- 173)

Reassembly

Reassembly

1. INSTALL NO. 1 COOLER THERMISTOR

(a) Install the No. 1 cooler thermistor as shown in the

illustration.

NOTICE:

Be sure to insert the thermistor only once

because reinserting it will no ...

Blower unit

Blower unit

COMPONENTS

...

Other materials:

Uniform Tire Quality Grading

This information has been prepared in accordance with regulations

issued by the National Highway Traffic Safety Administration of the

U.S. Department of Transportation.

It provides the purchasers and/or prospective purchasers of Toyota

vehicles with information on uniform tire quality grading. ...

Disassembly

1. Remove repair service starter kit

(a) Remove the nut and disconnect the lead wire from

the repair service starter kit.

(b) Remove the 2 screws which are used to secure the

repair service starter kit to the repair service starter

kit.

(c) Remove the repair service starter kit.

( ...

Yaw rate sensor check (when using sst check wire)

(a) Check the zero point voltage of the yaw rate sensor.

(1) Keep the vehicle in a stationary condition on a

level surface for 1 second or more.

(b) Check the output of the yaw rate sensor.

(1) Move the shift lever to the D position, drive the

vehicle at a speed of approximately 3 mph (5

...