Toyota Sienna Service Manual: Installation

1. Install heated oxygen sensor (for bank 2 sensor 2) (see page ec-34)

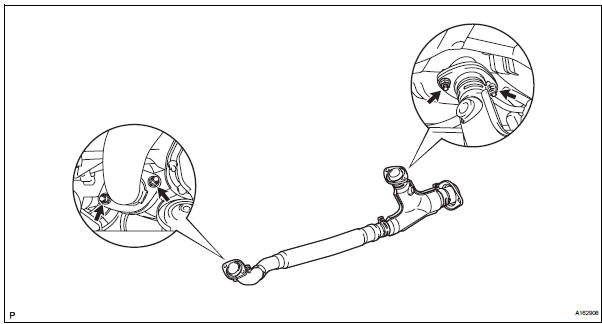

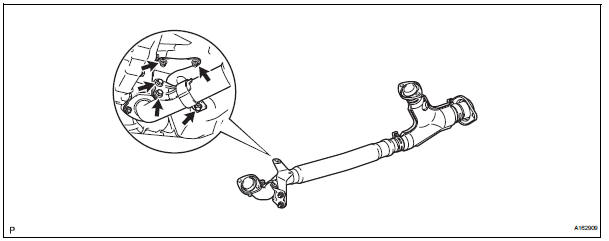

2. Install front exhaust pipe assembly

(a) Install 2 new gaskets to the front exhaust pipe assembly.

(b) Install the front exhaust pipe assembly with the 4 nuts.

Torque: 62 n*m (632 kgf*cm, 46 ft.*Lbf)

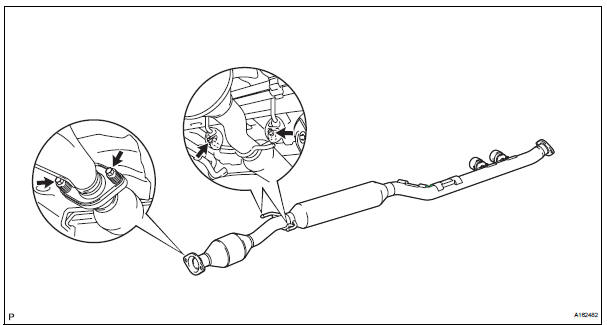

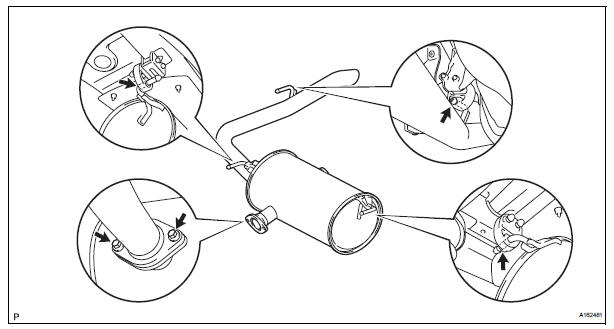

3. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Using a vernier caliper, measure the free length of the compression spring.

Minimum length: 38.86 mm (1.5299 in.)

If the length is less than the minimum, replace the compression spring.

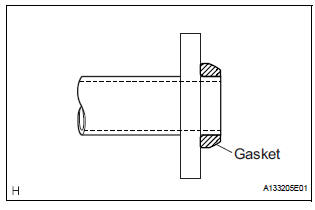

(b) Install a new gasket by hand so that its surface is flush with the front exhaust pipe assembly.

NOTICE:

|

(c) Connect the 2 exhaust pipe supports, and install the center exhaust pipe assembly.

(d) Install the 2 compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(e) Connect the heated oxygen sensor (for bank 2 sensor 2) connector.

4. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET

(a) Install the No. 1 exhaust pipe support bracket to oil pan sub-assembly with 2 new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (b) Loosen the No. 1 exhaust pipe support bracket bolts.

(c) Install the clamp to No. 1 exhaust pipe support bracket.

(d) Retighten the No. 1 exhaust pipe support bracket bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (e) Install the clamp with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

5. INSTALL TAIL EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

(b) Connect the 3 exhaust pipe supports, and install the tail exhaust pipe assembly.

(c) Install 2 new bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

6. INSTALL HEATED OXYGEN SENSOR (for Bank 1 Sensor 2) (See page EC-36) 7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

8. INSPECT FOR EXHAUST GAS LEAK

If exhaust gas is leaking, repair the leak. Replace damaged parts as necessary.

Removal

Removal

1. Disconnect cable from negative battery

terminal

2. REMOVE HEATED OXYGEN SENSOR (for Bank 1

Sensor 2) (See page EC-32)

3. REMOVE TAIL EXHAUST PIPE ASSEMBLY

(a) Remove the 2 bolts.

(b) Discon ...

Exhaust pipe (for 4wd)

Exhaust pipe (for 4wd)

Components

...

Other materials:

Precaution

1. Before operating the power rear no. 2 seat with

stowing function, make sure that there is nothing in

the path of the seat.

CAUTION:

If someone or something is caught between the seat

and other parts, injury or damage may result.

If the system detects that the folding motor is locke ...

Installation

1. INSTALL SIDE REAR WINDOW WEATHERSTRIP LH

2. INSTALL QUARTER WINDOW LOCK ASSEMBLY LH

3. INSTALL POWER VENT WINDOW MOTOR

ASSEMBLY LH

4. INSTALL SIDE WINDOW ASSEMBLY REAR LH

5. INSTALL RR WINDOW SIDE GARNISH ASSEMBLY

LH

6. INSTALL RR WINDOW SIDE GARNISH ASSEMBLY

NO.2 LH

7. REMOVE QUARTER TR ...

Disposal

HINT:

When scrapping a vehicle equipped with the SRS or

disposing of the steering pad, be sure to deploy the airbag

first in accordance with the procedure described below. If any

abnormality occurs with airbag deployment, contact the

SERVICE DEPT. of TOYOTA MOTOR SALES, U.S.A., INC.

CAUTION:

...