Toyota Sienna Service Manual: Installation

1. Install generator assembly

(a) Install the bracket with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

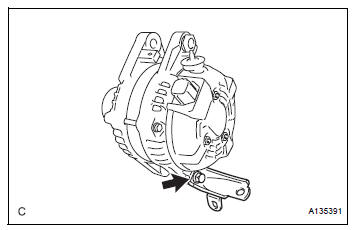

(b) Install the wire harness clamp stay.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

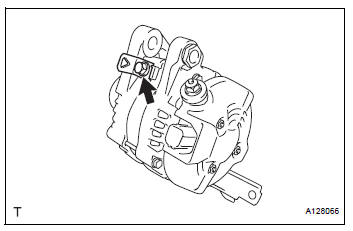

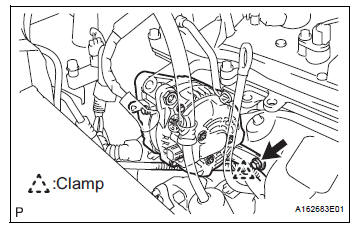

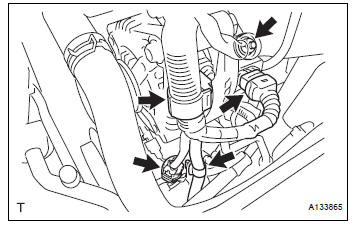

(c) Connect the wire harness clamp.

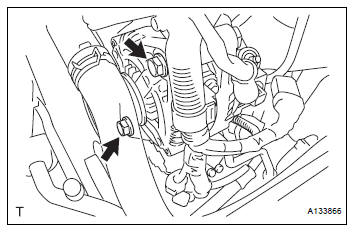

(d) Install the generator assembly to the cylinder block with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(e) Install the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

Connect the generator connector to the generator assembly.

(g) Install the generator wire with the nut.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf) (h) Install the terminal cap.

(i) Connect the 2 wire harness clamps.

(j) Connect the magnetic clutch connector to the compressor and magnetic clutch.

2. INSTALL V-RIBBED BELT (See page EM-7) 3. INSTALL RADIATOR ASSEMBLY WITH FAN SHROUD AND FAN MOTOR (See page CO-40) 4. INSTALL NO. 1 RADIATOR SUPPORT (See page CO- 40) 5. INSTALL RADIATOR SUPPORT CUSHION (See page CO-41) 6. REMOVE PRESSURE FEED TUBE ASSEMBLY (See page CO-41) 7. INSTALL HEADLIGHT BRACKET RH (See page CO- 41) 8. INSTALL RADIATOR SIDE DEFLECTOR RH (See page CO-41) 9. INSTALL HEADLIGHT ASSEMBLY RH (See page LI- 78) 10. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUBASSEMBLY (See page CO-41) 11. INSTALL RADIATOR UPPER SUPPORT SUBASSEMBLY (See page CO-42) 12. CONNECT COOLING FAN ECU CONNECTOR (See page CO-42) 13. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY (See page CO-43) 14. INSTALL HOOD LOCK ASSEMBLY (See page CO-43) 15. INSTALL HOOD LOCK RELEASE LEVER PROTECTOR (See page CO-44) 16. CONNECT NO. 2 RADIATOR HOSE (See page CO-44) 17. CONNECT NO. 1 RADIATOR HOSE (See page CO-44)

18. CONNECT RADIATOR RESERVE TANK HOSE OR PIPE (See page CO-44) 19. INSTALL NO. 1 AIR CLEANER INLET (See page EM- 59) 20. INSTALL FRONT BUMPER ENERGY ABSORBER 21. INSTALL FRONT BUMPER ASSEMBLY (See page ET- 9) 22. INSTALL BATTERY (See page EM-59) 23. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60) 24. ADD ENGINE COOLANT (See page CO-7) 25. INSPECT FOR COOLANT LEAK (See page CO-1) 26. ADD AUTOMATIC TRANSAXLE FLUID 27. CHECK AUTOMATIC TRANSAXLE FLUID (See page AX-123) 28. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62) 29. INSTALL NO. 1 ENGINE UNDER COVER (See page EM-63) 30. INSTALL FRONT WHEEL RH Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf) 31. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63) 32. VEHICLE PREPARATION FOR HEADLIGHT AIM ADJUSTMENT (See page LI-71) 33. PREPARATION FOR HEADLIGHT AIMING (Using a tester) (See page LI-71) 34. PREPARATION FOR HEADLIGHT AIMING (Using a Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74) 36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75) 37. VEHICLE PREPARATION FOR FOG LIGHT AIM ADJUSTMENT (w/ Fog Light) (See page LI-82) 38. PREPARATION FOR FOG LIGHT AIMING (Using a Screen) (w/ Fog Light) (See page LI-83) 39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See page LI-74) 40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light) (See page LI-85)

Reassembly

Reassembly

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

(b) Install the generator rotor assembly to the drive end

frame.

(c) Place a new generator washer ...

Other materials:

Cooling system

On-vehicle inspection

1. INSPECT FOR COOLANT LEAK

CAUTION:

Do not remove the radiator cap while the engine and

radiator are still hot. Pressurized, hot engine coolant

and steam may be released and cause serious

burns.

NOTICE:

Before performing each inspection, turn the A/ ...

Vehicle Speed Signal Circuit between Stereo Component Amplifier and

Combination Meter

DESCRIPTION

This circuit is necessary for the ASL (Auto Sound Leveliser) built into the

stereo component amplifier.

Speed signals are received from the combination meter and used for the ASL.

The ASL function automatically adjusts the sound data in order to enable hearing

the clear audio ...

Reassembly

1. INSTALL REAR DOOR WIRE SUB-ASSEMBLY LH

Install the wire.

NOTICE:

When installing the wire, push the areas where

the clips are installed in order to prevent

damage and deformation.

Install the 2 screws

2. INSTALL REAR DOOR LOCK ASSEMBLY LH

Apply MP grease to the slidin ...