Toyota Sienna Service Manual: On-vehicle inspection

1. INSPECT FUEL CUT RPM

(a) Increase the engine speed to at least 3500 rpm.

(b) Use a sound scope to check for injector operating sounds.

(c) Check that when the throttle lever is released, injector operating sounds stop momentarily (at 2500 rpm) and then resume (at 1400 rpm).

Standard

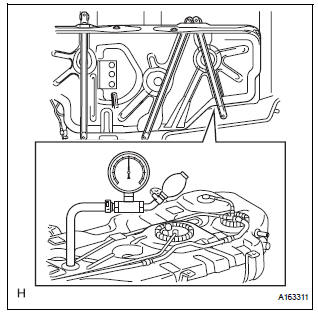

2. CHECK AIR TIGHTNESS IN FUEL TANK AND FILLER PIPE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Apply pressure to the fuel tank to create an internal pressure of 4 kPa (41 gf/cm2, 0.58 psi).

(d) Check that the internal pressure of the fuel tank is maintained for 1 minute.

(e) Check the connected portions of each hose and pipe.

(f) Check the installed parts on the fuel tank.

If any malfunctions, damage or other problems are found, replace the fuel tank and filler pipe.

(g) Reconnect the vent line hose to the fuel tank.

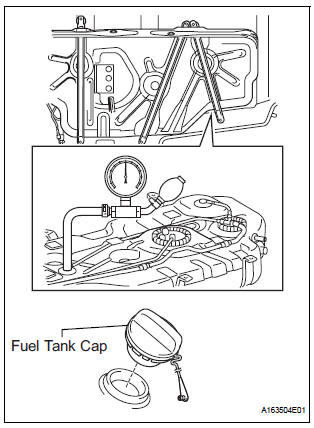

3. INSPECT FUEL CUT OFF VALVE AND FUEL CHECK VALVE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Fill the fuel tank with fuel.

(d) Apply pressure of 4 kPa (41 gf/cm2, 0.58 psi) to the vent port of the fuel tank.

HINT: Check the amount of fuel in the fuel tank. When the fuel tank is full, the float valve of the fill check valve is closed and no air can pass through.

(e) Remove the fuel tank cap, and check that the pressure drops.

If the pressure does not drop, replace the fuel tank assembly.

(f) Reconnect the vent line hose to the fuel tank.

4. CHECK AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or replace it.

(c) Reconnect the air inlet line hose to the charcoal canister.

5. VISUALLY INSPECT HOSES, CONNECTORS AND GASKETS

(a) Check for cracks, leaks or damage.

HINT:

Removal or problems with the engine oil dipstick, oil filler cap, PCV hose and other components may cause the engine to run improperly. Disconnection, looseness or cracks in the parts of the air induction system between the throttle body and cylinder head will allow air suction and cause the engine to run improperly.

If necessary, replace any damaged parts.

Parts location

Parts location

System diagram

...

Canister

Canister

Components

...

Other materials:

Enter test mode

HINT:

Operation of the tire pressure warning reset switch

can be checked in TEST MODE.

During TEST MODE, the system is not initialized by

pushing the tire pressure warning reset switch. The

circuit of the tire pressure warning reset switch can be

inspected during this mode.

(a) Make ...

Power Slide Door Warning Buzzer LH does not Sound

DESCRIPTION

The power slide door system uses warning buzzers built into LH

slide doors respectively. Each buzzer

has 2 ways of sounding that are used differently according to the

situations.

When all the following conditions are met, the warning buzzer sounds at

a cycle of ...

Replacement

1. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM

SST 07110-58060 (07117-58080, 07117-58090,

07117-78050, 07117-88060, 07117-88070,

07117-88080)

(a) Turn the A/C switch to ON.

(b) Operating the cooler compressor at the engine rpm

of approx. 1,000 for 5 to 6 minutes, circulate the

refriger ...