Toyota Sienna Service Manual: Open in CAN Main Bus Line

DESCRIPTION

There may be an open circuit in the CAN main bus wire and/or the DLC3 branch wire when the resistance between terminals 6 (CANH) and 14 (CANL) of the DLC3 is 69 Ω or higher.

|

Symptom |

Trouble Area |

| Resistance between terminals 6 (CANH) and 14 (CANL) of the DLC3 is 69 Ω or higher. |

|

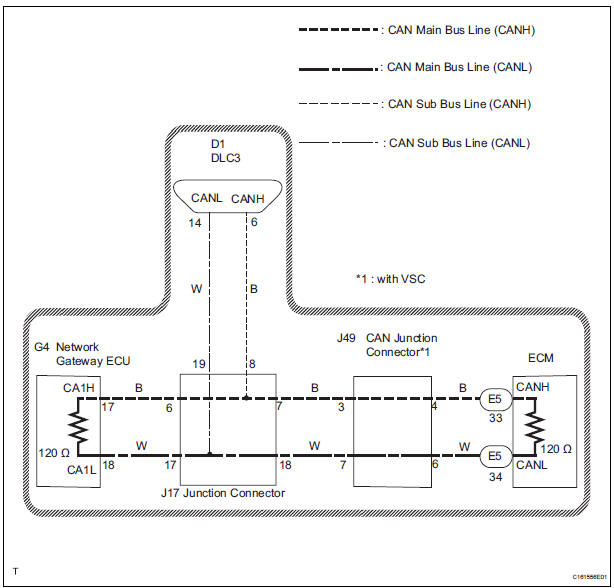

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

- Turn the ignition switch off before measuring the resistances of CAN bus main wires and CAN bus branch wires

- After the ignition switch is turned off, check that the key reminder warning system and light reminder warning system are not in operation.

- Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches, or the doors. If any doors need to be opened in order to check connectors, open the doors and leave them open.

HINT: Operating the ignition switch, any switches, or any doors triggers related ECU and sensor communication with the CAN. This communication will cause the resistance value to change

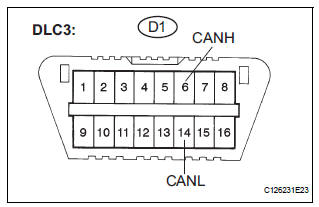

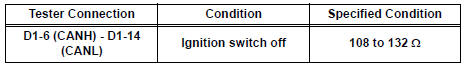

1 CHECK DLC3

- Turn the ignition switch off.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Result

NOTICE: When the measured value is 133 Ω or more and a CAN communication system diagnostic trouble code is output, there may be a fault besides disconnection of the DLC3 branch wire. For that reason, troubleshooting should be performed again from "HOW TO PROCEED WITH TROUBLESHOOTING" (See page CA-7 ) after repairing the trouble area.

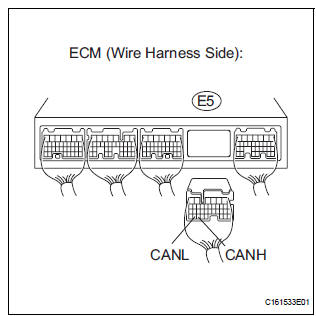

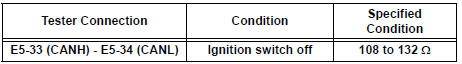

2 CHECK FOR OPEN IN CAN BUS MAIN WIRE (ECM CAN MAIN BUS WIRE)

- Turn the ignition switch off.

- Disconnect the ECM connector.

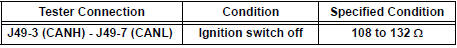

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE ECM

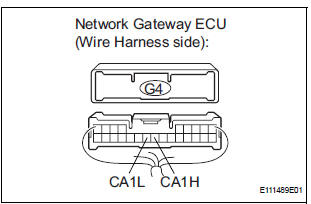

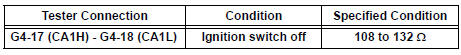

3 CHECK FOR OPEN IN CAN BUS MAIN WIRE (NETWORK GATEWAY ECU CAN MAIN BUS WIRE)

- Reconnect the ECM connector.

- Disconnect the network gateway ECU connector.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE NETWORK GATEWAY ECU

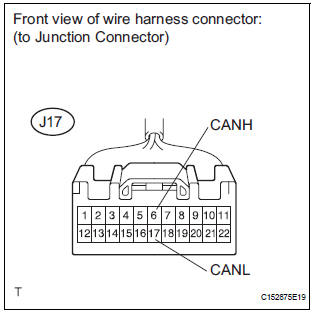

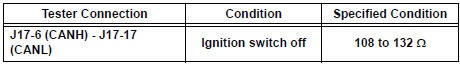

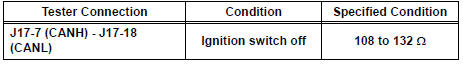

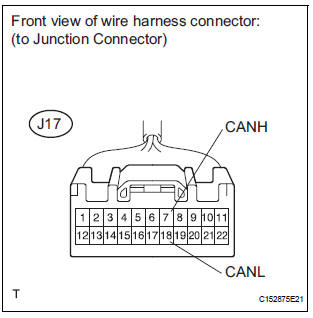

4 CHECK FOR OPEN IN CAN BUS MAIN WIRE (JUNCTION CONNECTOR - NETWORK GATEWAY ECU)

- Reconnect the network gateway ECU connector.

- Disconnect the junction connector (J17).

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Result

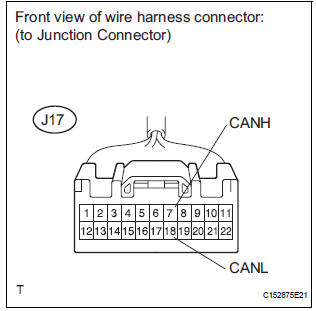

5 CHECK CHECK FOR OPEN IN CANBUS MAIN WIRE (JUNCTION CONNECTOR - ECM)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE WIRING HARNESS CONNECTOR (JUNCTION CONNECTOR)

6 CHECK FOR OPEN IN CAN BUS MAIN WIRE (JUNCTION CONNECTOR -Å@CAN JUNCTION CONNECTOR)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE WIRING HARNESS CONNECTOR (JUNCTION CONNECTOR)

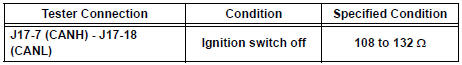

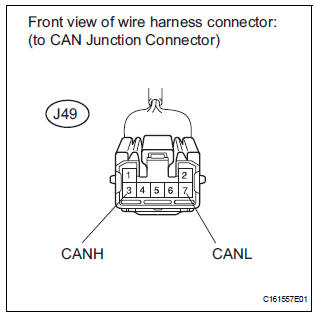

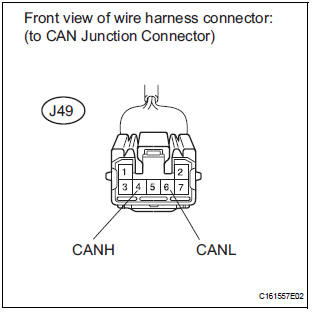

7 CHECK FOR OPEN IN CAN BUS MAIN WIRE (CAN JUNCTION CONNECTOR - JUNCTION CONNECTOR)

- Reconnect the junction connector (J17).

- Disconnect the CAN junction connector (J49).

- Measure the resistance according to the value(s) in the table below.

Standard resistance

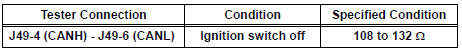

8 CHECK FOR OPEN IN CAN BUS MAIN WIRE (CAN JUNCTION CONNECTOR - ECM)

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE WIRING HARNESS CONNECTOR (CAN JUNCTION CONNECTOR)

CAN Bus Line

CAN Bus Line

DESCRIPTION

When any DTC for the CAN communication system is output, first measure the

resistance between the

terminals of the DLC3 to specify the trouble area, and check that there is no

short ...

Short in CAN Bus Lines

Short in CAN Bus Lines

DESCRIPTION

The CAN bus wires are considered to be shorted when the resistance between

terminals 6 (CANH) and

14 (CANL) of the DLC3 is below 54 Ω.

Symptom

Trouble Area

...

Other materials:

Do-it-yourself service

precautions

If you perform maintenance yourself, be sure to follow the correct

procedure as given in these sections.

Items

Parts and tools

Battery condition

Warm water

Baking soda

Grease

Conventional wrench (for terminal clamp bolts)

Brake ...

Disassembly

1. FIX FRONT SHOCK ABSORBER WITH COIL SPRING

(a) Install 2 nuts and a bolt to the bracket at the lower

side of the front shock absorber with coil spring and

secure it in a vise.

2. REMOVE FRONT SUSPENSION SUPPORT SUBASSEMBLY LH

(a) Using SST, compress the front coil spring LH

SST 09727-300 ...

Inspection

1. INSPECT CRANKSHAFT POSITION SENSOR

Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

NOTICE:

"Cold" and "Hot" mean the temperature of the

coils themselves.

"Cold" is from -10C (14F) to 50C (122F ...