Toyota Sienna Service Manual: Perform signal check

HINT:

- When entering signal check mode, the tire pressure

warning ECU sets all the signal check DTCs first.

After completing signal check for each inspection item, the DTCs for systems that are determined to be normal by the tire pressure warning ECU will be erased.

The DTCs for other inspection items may not be erased when only a certain signal is inspected.

- When signal check returns to normal mode, all the signal check DTCs will be erased.

(a) Make sure that the ignition switch is off.

(b) Connect the intelligent tester to DLC3.

(c) Turn the ignition switch to the ON position.

(d) Select the SIGNAL CHECK on the intelligent tester.

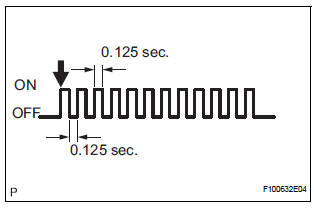

HINT: Every time the test mode DTC clear conditions are satisfied, the tire pressure warning light comes on for 1 second. Then, the tire pressure warning light blinks at 0.125-second intervals.

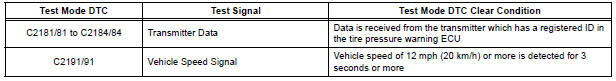

(e) Drive the vehicle at 12 mph (20 km/h) or more for 10 seconds or more to check the vehicle speed signal (C2191/91).

(f) Loosen the valve core and rapidly reduce the pressure (at least 40 kPa (0.41 kg/cm2, 5.8 psi) within 30 seconds or more) to check the transmitter data (C2181/81 to C2184/84).

HINT: The transmitter ID can be transmitted by rapidly reducing the tire pressure.

(g) Check that the tire pressure warning system test

mode DTCs are erased.

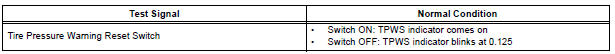

(h) Check the tire pressure warning reset switch.

(1) Press the tire pressure warning reset switch.

(2) Check the tire pressure warning indicator light.

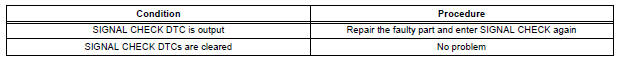

(i) Result

HINT:

After the signal check is completed, check for a

signal check DTC to confirm the system status

(j) End of SIGNAL CHECK

After completing the test mode (SIGNAL CHECK), turn the ignition switch off and disconnect the tester.

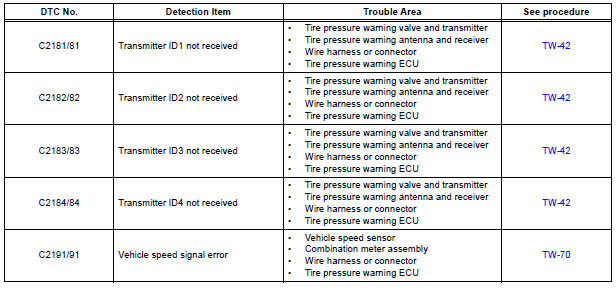

DTC of SIGNAL CHECK (TEST DIAGNOSIS)

function:

If a trouble code is displayed during the test mode

DTC check, check the circuit listed for that code. For

details of each code, refer to the relevant page listed

under respective "DTC No." in the chart.

Enter test mode

Enter test mode

HINT:

Operation of the tire pressure warning reset switch

can be checked in TEST MODE.

During TEST MODE, the system is not initialized by

pushing the tire pressure warning reset switch. The

...

Problem symptoms table

Problem symptoms table

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected Area"

column ...

Other materials:

Problem symptoms table

HINT:

Proceed to troubleshooting of each circuit in the table below.

1. HEADLIGHT AND TAIL LIGHT SYSTEM

2. AUTOMATIC LIGHT CONTROL SYSTEM

3. LIGHT AUTO TURN OFF SYSTEM

4. FOG LIGHT SYSTEM

5. TURN SIGNAL AND HAZARD WARNING SYSTEM

6. ILLUMINATED ENTRY SYSTEM

7. OTHE ...

Right Rear Wheel Speed Sensor Signal

DESCRIPTION

Refer to DTCs C0200/31, C0205/32, C1235/35 and C1236/36 (See page BC-92).

HINT:

DTC C0210/33 and C1238/38 are for the right rear speed sensor.

DTC C0215/34 and C1239/39 are for the left rear speed sensor.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 READ VALUE ON INTELL ...

Removal

HINT:

Replace the RH side using the same procedures as for the

LH side.

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE HUB LH NUT (See page DS-

5)

3. SEPARATE SPEED SENSOR FRONT LH (See page

DS-5)

4. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY LH

(a) Remove the 2 bolts and separate the front ...