Toyota Sienna Service Manual: Removal

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT: See page EM-26

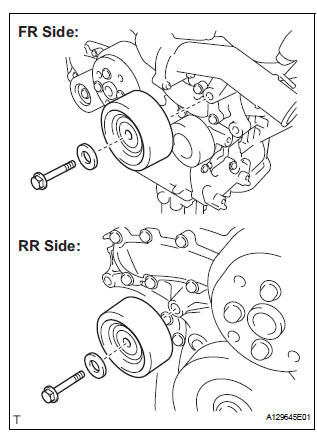

2. SECURE ENGINE (See page EM-37) 3. REMOVE GENERATOR ASSEMBLY (See page CH-17) 4. REMOVE COMPRESSOR AND MAGNETIC CLUTCH (See page AC-227) 5. REMOVE NO. 1 ENGINE FRONT MOUNTING BRACKET LH (See page EM-42) 6. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

(a) Remove the 2 bolts, 2 idler pulley cover plates and 2 idler pulley sub-assemblies.

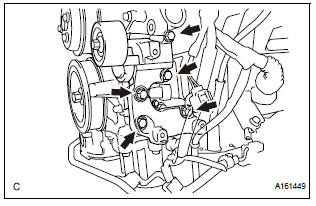

7. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(a) Remove the 5 bolts and V-ribbed belt tensioner assembly.

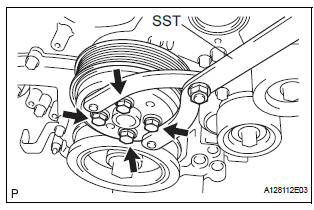

8. REMOVE WATER PUMP PULLEY

(a) Using SST, hold the water pump pulley.

SST 09960-10010 (09962-01000, 09963-00700) (b) Remove the 4 bolts and water pump pulley.

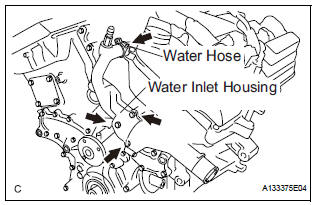

9. REMOVE WATER INLET HOUSING

(a) Disconnect the water hose.

(b) Remove the 2 bolts, nut and water inlet housing.

(c) Remove the water inlet housing gasket and water outlet pipe O-ring.

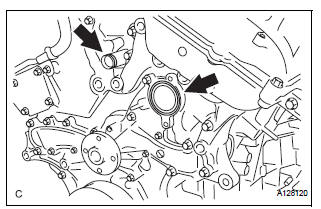

10. REMOVE WATER PUMP ASSEMBLY

(a) Remove the 16 bolts, water pump assembly and water pump gasket.

Water pump

Water pump

COMPONENTS

...

Inspection

Inspection

1. Inspect water pump assembly

(a) Visually check the drain hole and air hole for coolant

leakage.

(b) Turn the pulley, and check that the water pump

bearing moves smoothly and noiselessly.

...

Other materials:

If your vehicle overheats

The following may indicate that your vehicle is overheating.

The needle of the engine coolant temperature gauge

enters the red zone or a loss of engine power is experienced. (For

example, the vehicle speed does not increase.)

The warning message indicating overheats is shown on the

mult ...

Inspection

1. INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister for cracks or

damage.

If cracks or damage are found, replace the charcoal

canister assembly.

(b) Check charcoal canister operation.

(1) With the purge port closed, blow 1.67 kPa (17.0

gf/cm2, 0.24 psi) ...

Absence of Registration Unit/ No Response for Connection Check/ Last Mode

Error/ No Response Against ON / OFF Command/ Mode Status Error/ Slave Reset

DTC 01-D5 Absence of Registration Unit

DTC 01-D8 No Response for Connection Check

DTC 01-D9 Last Mode Error

DTC 01-DA No Response Against ON / OFF Command

DTC 01-DB Mode Status Error

DTC 01-DE Slave Reset

DESCRIPTION

HINT:

*1: Even if no fault is present, this trouble code may b ...