Toyota Sienna Service Manual: Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL 2. DRAIN ENGINE COOLANT 3. REMOVE FRONT WIPER ARM HEAD CAP (See page WW-4) 4. REMOVE FRONT WIPER ARM RH (See page WW-4) 5. REMOVE FRONT WIPER ARM LH (See page WW-4) 6. REMOVE COWL TOP VENTILATOR LOUVER SUBASSEMBLY (See page WW-4) 7. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (See page WW-4) 8. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER (See page FU-13) 9. REMOVE COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT (See page FU-13) 10. REMOVE NO. 1 ENGINE UNDER COVER 11. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28) 12. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page FU-13) 13. REMOVE INTAKE AIR SURGE TANK ASSEMBLY (See page FU-14) 14. REMOVE NO. 1 SURGE TANK STAY

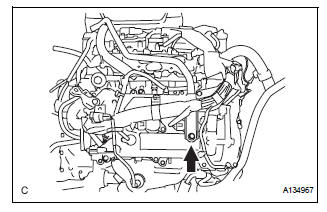

(a) Remove the 2 bolts and nut and disconnect the 2 harness clamps.

(b) Remove the bolt and No. 1 surge tank stay.

15. REMOVE IGNITION COIL ASSEMBLY

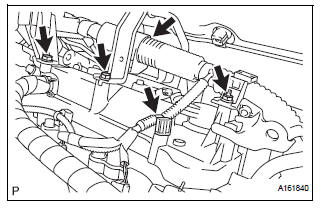

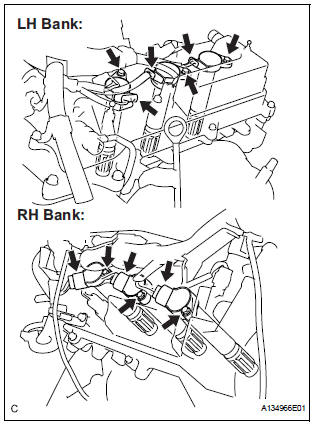

(a) Disconnect the 6 ignition coil connectors.

(b) Remove the 6 bolts and 6 ignition coils.

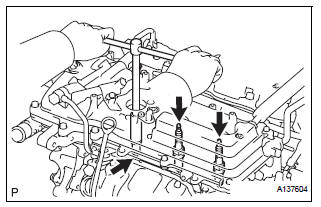

16. REMOVE SPARK PLUG

(a) Remove the 6 spark plugs.

On-vehicle inspection

On-vehicle inspection

NOTICE:

In this section, the terms "cold" and "hot" refer to the

temperature of the coils. "Cold" means approximately -

10°C (14°F) to 50°C (122°F). & ...

Installation

Installation

1. INSTALL SPARK PLUG

(a) Install the 6 spark plugs.

Torque: 18 N*m (183 kgf*cm, 13 ft.*lbf)

2. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coils with the 6 bolts.

Torqu ...

Other materials:

Navigation Voice Circuit

DESCRIPTION

This circuit is used when the voice guidance in the navigation system is on.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK HARNESS AND CONNECTOR (RADIO AND NAVIGATION ASSEMBLY - STEREO

COMPONENT AMPLIFIER)

Disconnect the radio and navigation assembly connector

R13 and s ...

Identification of noise source

1. Radio Description

Radio frequency band

Radio broadcasts use the radio frequency bands

shown in the table below

Service area

The service areas of AM and FM broadcasts are

vastly different. Sometimes an AM broadcast

can be received very clearly but an FM st ...

Short to B+ in Door System Communication

Bus Malfunction/ Short to GND in Door System Communication

Bus Malfunction

DTC B1214 Short to B+ in Door System Communication

Bus Malfunction

DTC B1215 Short to GND in Door System Communication

Bus Malfunction

DESCRIPTION

DTCs B1214 and B1215 are output when a short to +B or the body ground occurs

on the communication

bus. Detecting this condition disables all the ...