Toyota Sienna Service Manual: Short in Driver Side Squib Circuit

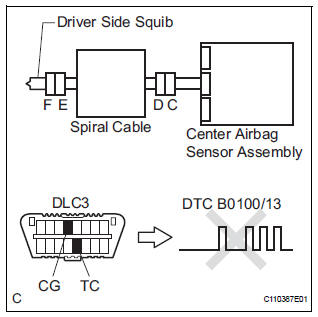

DTC B0100/13 Short in Driver Side Squib Circuit

DESCRIPTION

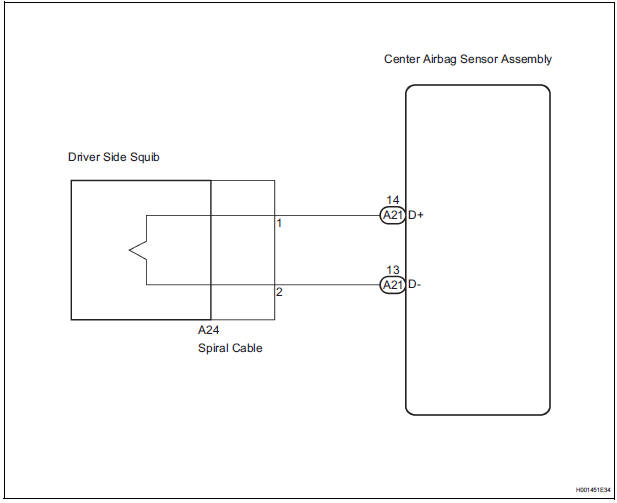

The driver side squib circuit consists of the center airbag sensor assembly, the spiral cable and the steering pad. The circuit instructs the SRS to deploy when deployment conditions are met. DTC B0100/13 is recorded when a short circuit is detected in the driver side squib circuit.

|

DTC No. |

DTC Detecting Condition |

Trouble Area |

|

B0100/13 |

|

|

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

- Perform the simulation method by selecting the "check mode" (signal check) with the intelligent tester

- After selecting the "check mode" (signal check), perform the simulation method by wiggling each connector of the airbag system or driving the vehicle on a city or rough road

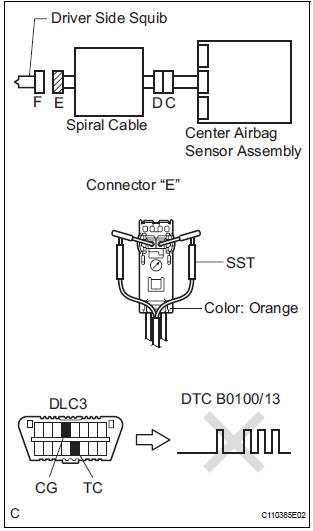

1 CHECK STEERING PAD (DRIVER SIDE SQUIB)

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- ) Disconnect the connectors from the steering pad.

- Connect the white wire side of SST (resistance 2.1 Ω) to the spiral cable.

CAUTION: Never connect a tester to the steering pad (driver side squib) for measurement, as this may lead to a serious injury due to airbag deployment.

NOTICE: Do not forcibly insert the SST into the terminals of the connector when connecting. Insert the SST straight into the terminals of the connector.

SST 09843-18060

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Clear the DTCs stored in memory (5).

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Check the DTCs (5).

OK: DTC B0100/13 is not output.

HINT: Codes other than DTC B0100/13 may be output at this time, but they are not related to this check.

Go to step 2

Go to step 2

REPLACE STEERING PAD

2 CHECK CONNECTORS

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Disconnect the SST (resistance 2.1 Ω) from the spiral cable.

- Check that the spiral cable connectors (on the steering pad side) are not damaged.

OK: The lock button is not disengaged, and the claw of the lock is not deformed or damaged.

REPLACE SPIRAL CABLE

REPLACE SPIRAL CABLE

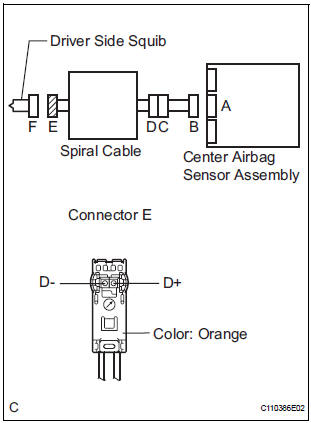

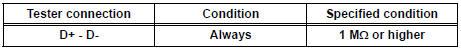

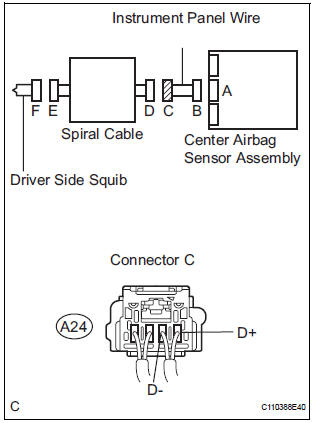

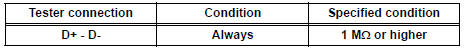

3 CHECK DRIVER SIDE SQUIB CIRCUIT

- Disconnect the connector from the center airbag sensor assembly.

- Release the activation prevention mechanism built into connector "B" (7).

- Measure the resistance according to the value(s) in the table below.

Standard resistance

Go to step 5

Go to step 5

4 CHECK CENTER AIRBAG SENSOR ASSEMBLY

- Connect the connectors to the steering pad and the center airbag sensor assembly.

- Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Clear the DTCs stored in memory (5).

- Turn the ignition switch to the LOCK position.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Check the DTCs (5).

OK: DTC B0100/13 is not output.

HINT: Codes other than code B0100/13 may be output at this time, but they are not related to this check.

REPLACE CENTER AIRBAG SENSOR

ASSEMBLY

REPLACE CENTER AIRBAG SENSOR

ASSEMBLY

USE SIMULATION METHOD TO CHECK

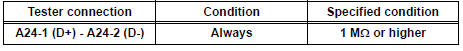

5 CHECK INSTRUMENT PANEL WIRE

- Disconnect the instrument panel wire connector from the

spiral cable.

HINT: The activation prevention mechanism of connector "B" has already been released.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPAIR OR REPLACE INSTRUMENT

PANEL

WIRE

REPAIR OR REPLACE INSTRUMENT

PANEL

WIRE

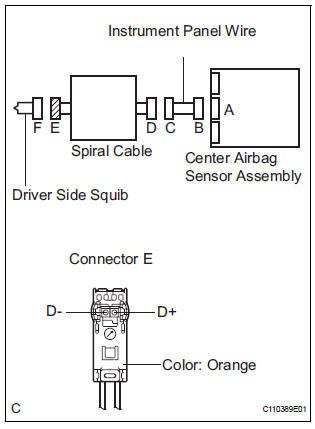

6 CHECK SPIRAL CABLE

- Release the activation prevention mechanism built into connector "D" (7).

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE SPIRAL CABLE

REPLACE SPIRAL CABLE

USE SIMULATION METHOD TO CHECK

Diagnostic trouble code chart

Diagnostic trouble code chart

1. DTCS FOR AIRBAG SYSTEM

If a malfunction code is displayed during the DTC check,

check the circuit listed for the code in the table below

(Proceed to the page listed for that circuit).

HINT:

...

Open in Driver Side Squib Circuit

Open in Driver Side Squib Circuit

DTC B0101/14 Open in Driver Side Squib Circuit

DESCRIPTION

The driver side squib circuit consists of the center airbag sensor assembly,

the spiral cable and the

steering pad.

The circuit instr ...

Other materials:

Driving tips

Winter driving tips

Carry out the necessary preparations and inspections before

driving the vehicle in winter. Always drive the vehicle in a manner

appropriate to the prevailing weather conditions.

Preparation for winter

Use fluids that are appropriate to the prevailing outside temperatures. ...

Diagnostic trouble code chart

If a trouble code is displayed during the DTC check, check

the circuit listed for that code. For details of each code, turn

the page mentioned below the "DTC No" in the DTC chart.

the "DTC No" in the DTC chart.

1. TRANSPONDER KEY ECU DIAGNOSTIC TROUBLE

CODE CHART

TRANSPON ...

System description

1. DESCRIPTION OF OCCUPANT CLASSIFICATION SYSTEM

GENERAL DESCRIPTION.

In the occupant classification system, the

occupant classification ECU calculates the

weight of the occupant based on a signal from

the occupant classification sensors. This system

recognizes the occu ...