Toyota Sienna Service Manual: Yaw rate sensor check (when using sst check wire)

(a) Check the zero point voltage of the yaw rate sensor.

(1) Keep the vehicle in a stationary condition on a level surface for 1 second or more.

(b) Check the output of the yaw rate sensor.

(1) Move the shift lever to the D position, drive the vehicle at a speed of approximately 3 mph (5 km/h), and turn the steering wheel either to the left or right 90° or more until the vehicle makes 180° turn.

(2) Stop the vehicle and move the shift lever to the position. Check that the skid control buzzer sounds for 3 seconds.

HINT:

- If the skid control buzzer sounds, the signal check is completed normally.

- If the skid control buzzer does not sound, check the skid control buzzer circuit, then perform the signal check again.

- If the skid control buzzer does not sound yet, there is a malfunction in the yaw rate sensor, so check the DTC.

- Make a 180° turn. At the end of the turn, the direction of the vehicle should be within 180 +- 5° of its start position.

- Do not spin the wheels.

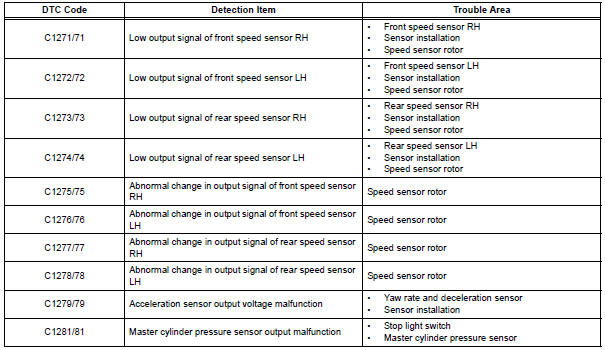

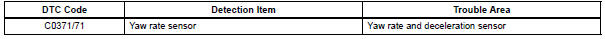

11. DTC OF TEST MODE (SIGNAL CHECK) FUNCTION

ABS sensor:

VSC sensor:

HINT: The codes in this table are output only in Test Mode (signal check).

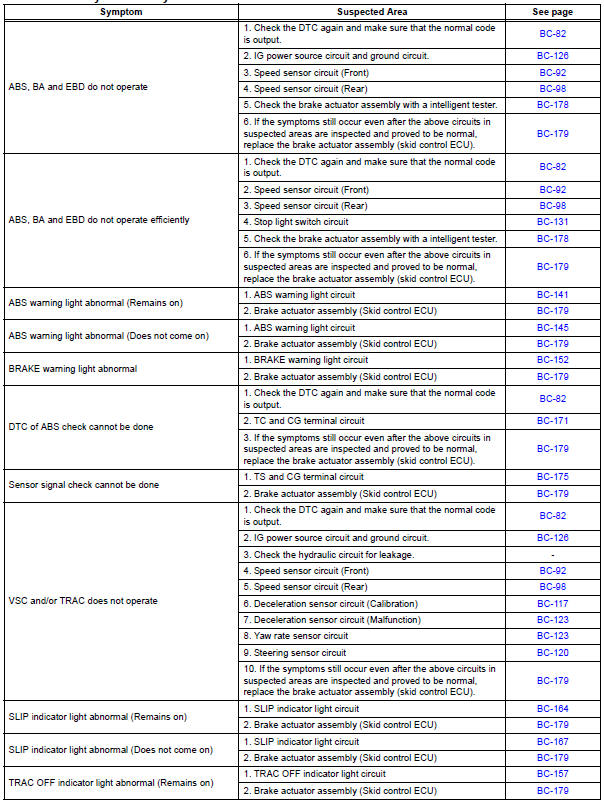

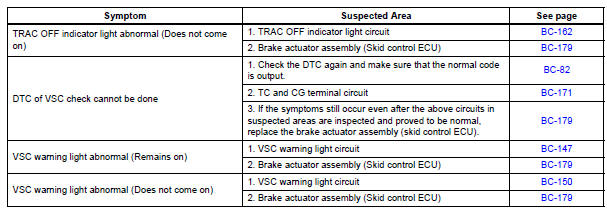

Problem symptoms table

Vehicle Stability Control System:

Speed sensor check (when using sst check wire)

Speed sensor check (when using sst check wire)

(a) Check the speed sensor signal.

(1) Drive the vehicle straight forward. Drive the

vehicle at a speed of 45 km/h (28 mph) or higher

for several seconds and check that the ABS

warning light goe ...

Terminals of ecu

Terminals of ecu

1. Terminal of ECU

(*1): Models with dynamic laser cruise control

(*2): 2WD model

2. Terminal Inspection

(a) Disconnect the connector and measure the voltage

or resistance on the wire harness ...

Other materials:

Folding and extending the mirrors

Manual type

Push the mirror back in the direction

of the vehicle’s rear.

Power type

Press the switch.

Folding

Extending

...

Operation check

1. INPUT SIGNAL CHECK

Connect the intelligent tester to the DLC3.

Check the cruise control main switch using the

DATA LIST function in the intelligent tester (ONOFF,

CANCEL, - (COAST)/SET, + (ACCEL)/RES

(RESUME), and MODE).

2. INSPECT MODE SWITCH

Turn the ...

Rear window wiper and

washer

Operating the wiper lever

Turning the end of the lever turns on the rear window wiper and

washer.

The illustration is intended as an example.

*1 or

*2

Intermittent window

wiper operation

*1 or

*2

Normal window wiper

operation

Washer/wiper dual operation

Washer/wiper du ...