Toyota Sienna Service Manual: Check mode procedure

HINT: Intelligent tester only: Compared to normal mode, check mode is more sensitive to malfunctions. Therefore, check mode can detect the malfunctions that cannot be detected by normal mode.

NOTICE: All the stored DTCs and freeze frame data are erased if:

- the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned off or

turned to the ACC position from the ON position while in

check mode.

Before changing modes, always check and make a note of any DTCs and freeze frame data.

1. CHECK MODE PROCEDURE (Using an intelligent tester)

- Check and ensure the following conditions:

- Battery voltage 12 V or more

- Throttle valve fully closed

- The shift lever in the P or N position

- A/C switched OFF

- Turn the ignition switch off.

- Connect an intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Select the following menu items: DIAGNOSIS / ENHANCED OBD II / CHECK MODE.

- Switch the ECM from normal mode to check mode.

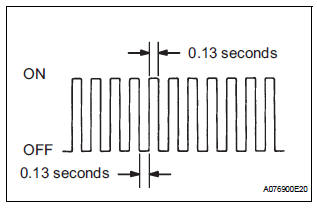

- Make sure that the MIL flashes as shown in the illustration.

- Start the engine.

- Make sure that the MIL goes off.

- Simulate the conditions of the malfunction described by the customer.

- Check for DTCs and freeze frame data using the tester.

Freeze frame data

Freeze frame data

1. DESCRIPTION

The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in dete ...

Fail-safe chart

Fail-safe chart

If any of the following DTCs are set, the ECM enters fail-safe

mode to allow the vehicle to be driven temporarily.

HINT:

*1: The vehicle can be driven slowly when the accelerator

ped ...

Other materials:

Turning the high beam on/off manually

Switching to low beam

Pull the lever to the original

position.

Switching to high beam

Turn the light switch to the

position.

The Automatic High Beam can be operated when

The engine switch is in the “ON” position (vehicles without a smart key

system)

or IGNITION ON mode (vehicl ...

Jam Protection Function Activates During Power Slide Door RH

Operation

DESCRIPTION

It may be caused by ill-fitting slide door, faulty touch sensor or

faulty pulse sensor.

The power slide door ECU activates the slide motor to open / close

the power slide door, thus

controlling the power slide door operation. For jam and foreign object

detect ...

Installation

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

Only when reusing the bolts and nuts, apply

the small amount of engine oil ...