Toyota Sienna Service Manual: Disassembly

1. INSPECT PACK CLEARANCE OF REVERSE CLUTCH

HINT: (See page AX-249)

2. INSPECT PACK CLEARANCE OF DIRECT CLUTCH AND OVERDRIVE CLUTCH

HINT: (See page AX-249)

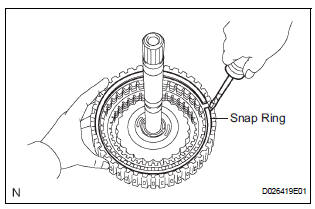

3. REMOVE DIRECT MULTIPLE DISC CLUTCH DISC

(a) Using a screwdriver, remove the snap ring from the intermediate shaft.

(b) Remove the flange, 3 discs, 3 plates and cushion plate from the intermediate shaft.

4. REMOVE OVERDRIVE DIRECT CLUTCH DISC

(a) Using a screwdriver, remove the snap ring from the intermediate shaft.

(b) Remove the flange, 4 discs and 4 plates from the intermediate shaft.

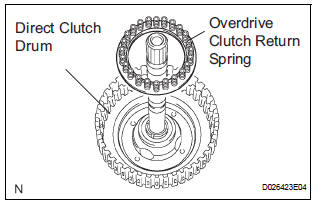

5. REMOVE OVERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

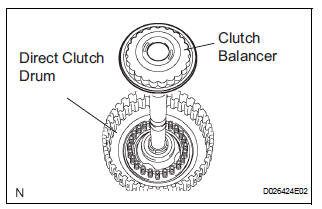

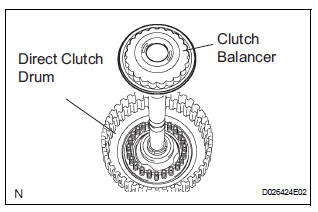

(a) Place SST on the clutch balancer and compress the spring with a press.

SST 09387-00020

(b) Using a snap ring expander, remove the snap ring from the direct clutch drum.

NOTICE:

- Stop the press when the spring seat is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove.

- This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

- This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

(c) Remove the clutch balancer from the direct clutch drum.

(d) Remove the overdrive clutch return spring from the direct clutch drum.

6. REMOVE OVERDRIVE DIRECT CLUTCH PISTON

(a) Install the intermediate shaft on the transaxle rear cover.

(b) Holding the direct clutch piston with your hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle rear cover to remove the direct clutch piston.

7. REMOVE OVERDRIVE DIRECT CLUTCH DRUM SUBASSEMBLY

(a) Holding the direct clutch drum by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle rear cover to remove the direct clutch drum.

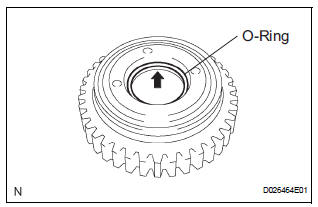

8. REMOVE OVERDRIVE DIRECT CLUTCH O-RING

(a) Using a screwdriver, remove the O-ring from the direct clutch drum.

Direct clutch

Direct clutch

Components

...

Inspection

Inspection

1. Inspect pack clearance of reverse clutch

(A) install the intermediate shaft and needle roller

bearing onto the transaxle rear cover.

(B) using a dial indicator, measure the reverse clutch

...

Other materials:

Open in Rear Curtain Shield Squib RH Circuit

DTC B1631/84 Open in Rear Curtain Shield Squib RH Circuit

DESCRIPTION

The rear curtain shield squib RH circuit consists of the center airbag sensor

assembly and the curtain

shield airbag assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1631/84 ...

Identification of noise source

1. Radio Description

Radio frequency band

Radio broadcasts use the radio frequency bands

shown in the table below

Service area

The service areas of AM and FM broadcasts are

vastly different. Sometimes an AM broadcast

can be received very clearly but an FM st ...

Rear Occupant Classification Sensor LH Circuit

Malfunction

DTC B1782 Rear Occupant Classification Sensor LH Circuit

Malfunction

DESCRIPTION

The rear occupant classification sensor LH circuit consists of the occupant

classification ECU and the rear

occupant classification sensor LH.

DTC B1782 is recorded when a malfunction is detected in the rear oc ...