Toyota Sienna Service Manual: Evaporative Emission Control System Leak Detected

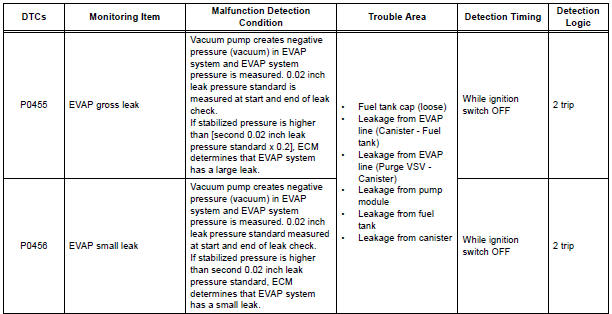

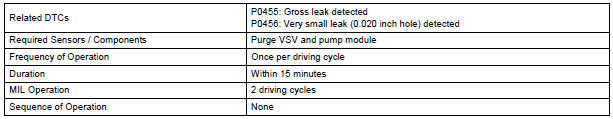

DTC P0455 Evaporative Emission Control System Leak Detected (Gross Leak)

DTC P0456 Evaporative Emission Control System Leak Detected (Very Small Leak)

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System.

INSPECTION PROCEDURE

Refer to the EVAP System.

MONITOR DESCRIPTION

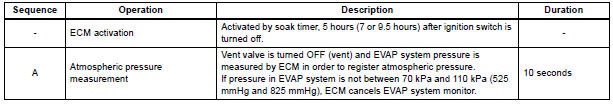

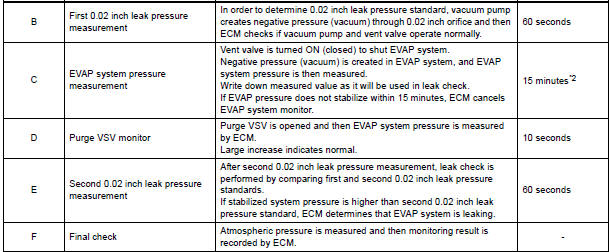

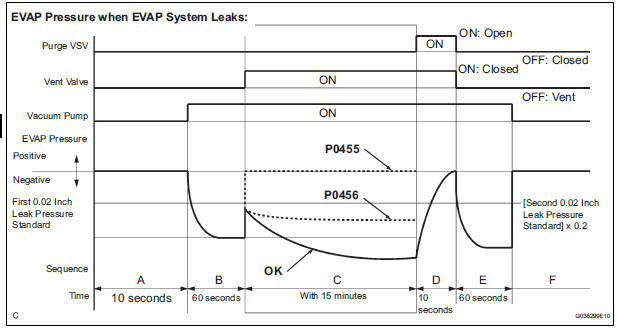

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure (vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT: *1: If the engine coolant temperature is not below 35C (95F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35C (95F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

*2: If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

- P0455: EVAP (Evaporative Emission) gross leak

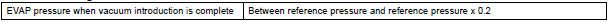

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP system and the EVAP system pressure is measured. If the stabilized system pressure is higher than [second 0.02 inch leak pressure standard x 0.2] (near atmospheric pressure), the ECM determines that the EVAP system has a large leak, illuminates the MIL and sets the DTC (2 trip detection logic). - 2. P0456: EVAP very small leak

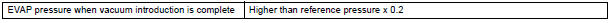

In operation C, the vacuum pump creates negative pressure (vacuum) in the EVAP system and the EVAP system pressure is measured. If the stabilized system pressure is higher than second 0.02 inch leak pressure standard, the ECM determines that the EVAP system has a small leak, illuminates the MIL and sets the DTC (2 trip detection logic).

MONITOR STRATEGY

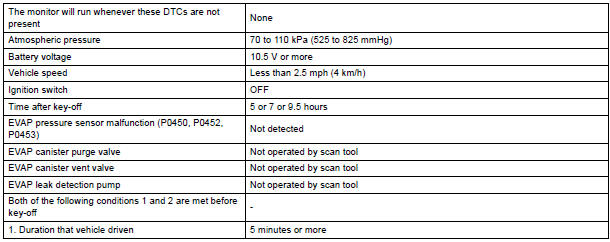

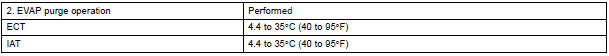

TYPICAL ENABLING CONDITIONS

Key-off monitor sequence 1 to 8

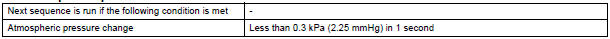

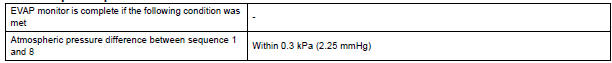

1. Atmospheric pressure measurement

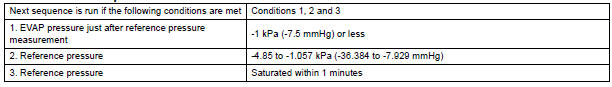

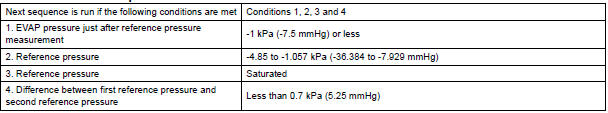

2. First reference pressure measurement

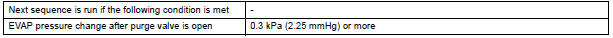

3. EVAP canister vent valve close stuck check

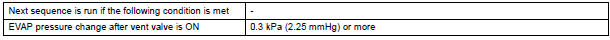

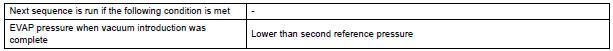

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

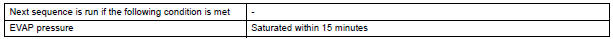

7. Leak check

8. Atmospheric pressure measurement

TYPICAL MALFUNCTION THRESHOLDS

P0455: EVAP gross leak

P0456: EVAP 0.02 inch leak

MONITOR RESULT

Refer to CHECKING MONITOR STATUS

Evaporative Emission Control System Pressure

Evaporative Emission Control System Pressure

DTC P0450 Evaporative Emission Control System Pressure

Sensor / Switch

DTC P0451 Evaporative Emission Control System Pressure

Sensor Range / Performance

DTC P0452 Evaporative Emission Control Syst ...

Vehicle Speed Sensor "A"

Vehicle Speed Sensor "A"

DTC P0500 Vehicle Speed Sensor "A"

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU.

The skid control ECU converts these ...

Other materials:

High Temperature

DTC 63-47 High Temperature

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

63-47

Sensor detects that CD unit temperature is high (Over

80C).

Radio and navigation assembly

INSPECTION PROCEDURE

HINT:

After the inspection is completed, c ...

System description

1. CRUISE CONTROL SYSTEM

This system is controlled by the ECM, and is activated by

the throttle position sensor and motor. The ECM controls

the following functions: ON-OFF, - (COAST)/SET, +

(ACCEL)/RES (RESUME), CANCEL, vehicle speed

operation, motor output control, and overdrive control.

& ...

Operating the meter control switches

The multi-information display is

operated using the meter control

switches.

Enter/Set

Select an item/Change pages

Return to the previous screen

Press: Displays the screen registered

as the top screen

When no screen has been registered, the drive information screen will be

displ ...