Toyota Sienna Service Manual: Inspection

1. INSPECT OIL PUMP RELIEF VALVE

(a) Coat the relief valve with engine oil and check that it falls smoothly into the valve hole under its own weight.

If the valve does not fall smoothly, replace the relief valve. If necessary, replace the oil pump assembly.

2. INSPECT OIL PUMP ROTOR SET

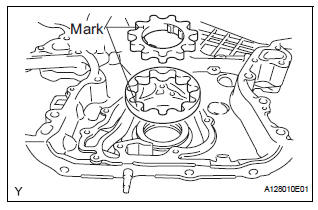

(a) Install the rotors to the timing chain cover with the rotors' marks facing outward. Check that the rotors rotate smoothly.

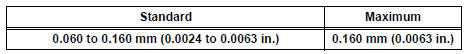

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance between the drive and driven rotors, as shown in the illustration.

Tip clearance

If the clearance is greater than the maximum, replace the drive and driven rotors.

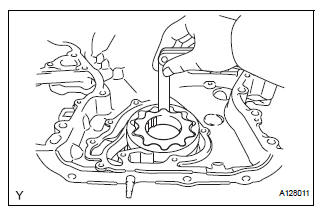

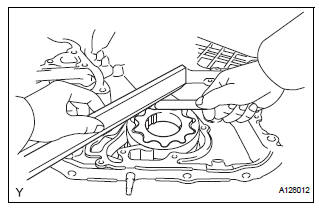

(c) Check the side clearance.

(1) Using a feeler gauge and precision straightedge, measure the clearance between the rotors and precision straightedge, as shown in the illustration.

Side clearance

If the side clearance is greater than the maximum, replace the timing chain cover.

(d) Check the body clearance.

(1) Using a feeler gauge, measure the clearance between the timing chain cover and driven rotor, as shown in the illustration.

Body clearance

If the body clearance is greater than the maximum, replace the timing chain cover.

Disassembly

Disassembly

1. REMOVE OIL PUMP RELIEF VALVE

(A) using a 27 mm socket wrench, remove the relief

valve plug.

(B) remove the valve spring and oil pump relief valve.

2. REMOVE OIL PUMP COVER

(a) Remove ...

Reassembly

Reassembly

1. INSTALL OIL PUMP COVER

(a) Coat the drive and driven rotors with engine oil and

place them into the timing chain cover with the

marks facing outward (oil pump cover side). Check

that the ro ...

Other materials:

Throttle Actuator Control Motor Current Range / Performance

DESCRIPTION

The ETCS (Electronic Throttle Control System) has a dedicated power supply

circuit. The voltage (+BM)

is monitored and when it is low (less than 4 V), the ECM determines that there

is a malfunction in the

ETCS and cuts off the current to the throttle actuator.

When the volt ...

Open in Curtain Shield Squib RH Circuit

DTC B1161/84 Open in Curtain Shield Squib RH Circuit

DESCRIPTION

The curtain shield squib RH circuit consists of the center airbag sensor

assembly and the curtain shield

airbag assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1161/84 is recorde ...

Oil and oil filter

COMPONENTS

REPLACEMENT

CAUTION:

Prolonged and repeated contact with engine oil will

result in the removal of natural oils from the skin,

leading to dryness, irritation and dermatitis. In

addition, used engine oil contains potentially harmful

contaminants which may caus ...