Toyota Sienna Service Manual: Installation

1. Install heated oxygen sensor (for bank 2 sensor 2) (see page ec-34)

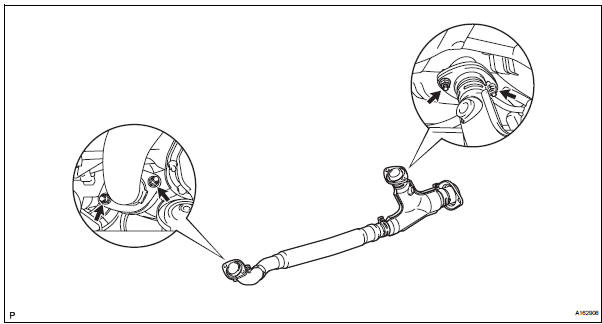

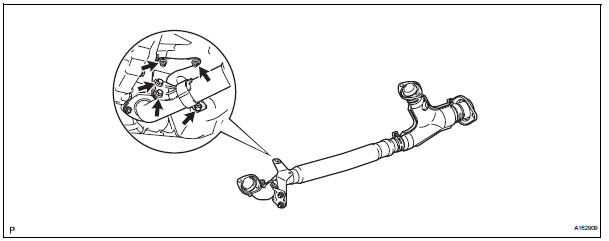

2. Install front exhaust pipe assembly

(a) Install 2 new gaskets to the front exhaust pipe assembly.

(b) Install the front exhaust pipe assembly with the 4 nuts.

Torque: 62 n*m (632 kgf*cm, 46 ft.*Lbf)

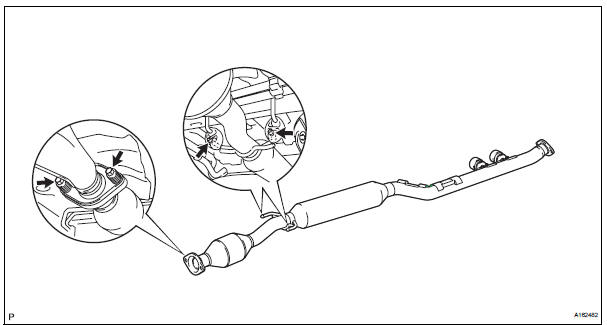

3. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Using a vernier caliper, measure the free length of the compression spring.

Minimum length: 38.86 mm (1.5299 in.)

If the length is less than the minimum, replace the compression spring.

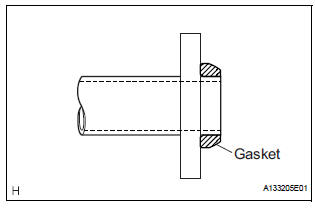

(b) Install a new gasket by hand so that its surface is flush with the front exhaust pipe assembly.

NOTICE:

|

(c) Connect the 2 exhaust pipe supports, and install the center exhaust pipe assembly.

(d) Install the 2 compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(e) Connect the heated oxygen sensor (for bank 2 sensor 2) connector.

4. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET

(a) Install the No. 1 exhaust pipe support bracket to oil pan sub-assembly with 2 new nuts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (b) Loosen the No. 1 exhaust pipe support bracket bolts.

(c) Install the clamp to No. 1 exhaust pipe support bracket.

(d) Retighten the No. 1 exhaust pipe support bracket bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (e) Install the clamp with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

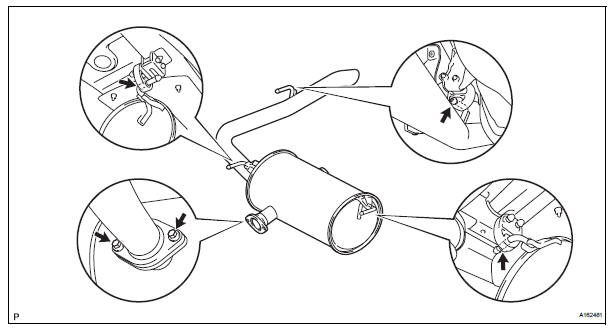

5. INSTALL TAIL EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

(b) Connect the 3 exhaust pipe supports, and install the tail exhaust pipe assembly.

(c) Install 2 new bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

6. INSTALL HEATED OXYGEN SENSOR (for Bank 1 Sensor 2) (See page EC-36) 7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

8. INSPECT FOR EXHAUST GAS LEAK

If exhaust gas is leaking, repair the leak. Replace damaged parts as necessary.

Removal

Removal

1. Disconnect cable from negative battery

terminal

2. REMOVE HEATED OXYGEN SENSOR (for Bank 1

Sensor 2) (See page EC-32)

3. REMOVE TAIL EXHAUST PIPE ASSEMBLY

(a) Remove the 2 bolts.

(b) Discon ...

Exhaust pipe (for 4wd)

Exhaust pipe (for 4wd)

Components

...

Other materials:

Side Airbag Sensor Assembly LH Circuit Malfunction

DTC B1141/33 Side Airbag Sensor Assembly LH Circuit Malfunction

DESCRIPTION

The side airbag sensor LH circuit consists of the center airbag sensor

assembly and side airbag sensor

LH.

If the center airbag sensor assembly receives signals from the side airbag

sensor LH, it judges whether or

...

Installation

1. INSTALL OCCUPANT CLASSIFICATION ECU

Check that the ignition switch is off.

Check that the negative battery (-) terminal is

disconnected.

CAUTION:

After disconnecting the negative battery

terminal, wait for at least 90 seconds before

starting the operation.

...

Removal

1. PRECAUTION

CAUTION: Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE FRONT SEAT ASSEMBLY (for Manual Seat)

4. REMOVE ...