Toyota Sienna Service Manual: Installation

1. Install transmission valve body assembly

(a) Install the shift solenoid valve SL1 to the valve body assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(b) Install the shift solenoid valve SL2 to the valve body assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(c) Install the shift solenoid valve DSL to the valve body assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(d) Install the shift solenoid valve SR to the valve body assembly.

(e) Install the shift solenoid valve S4 to the valve body assembly with the bolt.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(f) Install the shift solenoid valve SL3 and SLT to the valve body assembly.

(g) Install the lock plate to the valve body assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(h) Install the spring and check ball body.

(i) Align the groove of the manual valve with the pin of the lever.

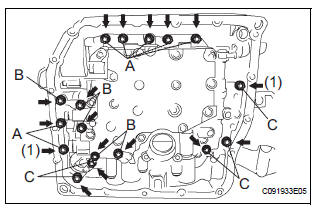

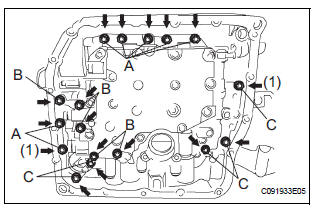

(j) Install the 17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

(i) Align the groove of the manual valve with the pin of the lever.

(j) Install the 17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

NOTICE:

|

Bolt length: Bolt A: 41 mm (1.614 in.) Bolt B: 57 mm (2.244 in.) Bolt C: 25 mm (0.984 in.)

2. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF.

(b) Install the O-ring to the oil strainer.

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

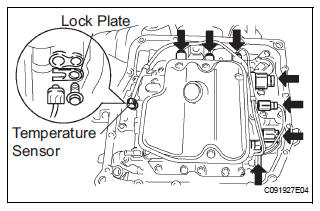

3. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

(b) Install the ATF temperature sensor with the lock plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf) (c) Connect the 7 shift solenoid valve connectors.

4. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUBASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing or equivalent to the 18 bolts.

Seal packing: THREE BOND 2430 or equivalent

(c) Install the oil pan and new gasket with the 18 bolts to the transaxle case.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

| NOTICE: Tighten the bolts within 10 minutes of sealant application. |

5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL 6. ADD AUTOMATIC TRANSAXLE FLUID 7. CHECK FLUID LEVEL IN AUTOMATIC TRANSAXLE (See page AX-123) 8. INSTALL ENGINE UNDER COVER NO.1 9. RESET MEMORY

HINT: (See page AX-16)

Removal

Removal

1. Remove engine under cover no.1

2. Disconnect cable from negative battery

terminal

3. Drain automatic transaxle fluid (see page

ax-131)

4. Remove automatic transaxle oil pan subassembly

(a ...

Shift lock system

Shift lock system

On-vehicle inspection

1. CHECK SHIFT LOCK OPERATION

(a) Move the shift lever to the P position.

(b) Turn the ignition switch to the LOCK position.

(c) Check that the shift lever cannot be move ...

Other materials:

Fastening the seat belt (for the third center seat)

Take the plate out of the holder,

and then pull down the seat

belt.

Push plate “A” into buckle “A”

until a click sound is heard.

Push plate “B” into buckle “B”

until a click sound is heard.

...

Installation

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

Only when reusing the bolts and nuts, apply

the small amount of engine oil ...

Turning on the high beam headlights

With the headlights on, push

the lever away from you to turn

on the high beams.

When the light switch is in

position, the Automatic High Beam

system will be activated.

Pull the lever toward you to the

center position to turn the high

beams off.

Pull the lever toward you and ...