Toyota Sienna Service Manual: Shift lock system

On-vehicle inspection

1. CHECK SHIFT LOCK OPERATION

(a) Move the shift lever to the P position.

(b) Turn the ignition switch to the LOCK position.

(c) Check that the shift lever cannot be moved to any position other than P.

(d) Turn the ignition switch to the on position, depress the brake pedal and check that the shift lever can be moved to another position. If operation can not be done as specified, inspect the shift lock control unit.

2. CHECK SHIFT LOCK RELEASE BUTTON OPERATION

(a) Using a small screwdriver, remove the shift lock release cover.

(b) When operating the shift lever with the shift lock release button pressed, check that the lever can be moved to any position other than P.

If operation can not be done as specified, check the shift lever assembly installation condition.

3. CHECK KEY INTERLOCK OPERATION

(a) Turn the ignition switch to the ON position.

(b) Depress the brake pedal and move the shift lever to any position other than P.

(c) Check that the ignition key cannot be turned to the LOCK position.

(d) Move the shift lever to the P position, turn the ignition key to the LOCK position and check that the ignition key can be removed.

If operation cannot be done as specified, inspect the shift lock control unit.

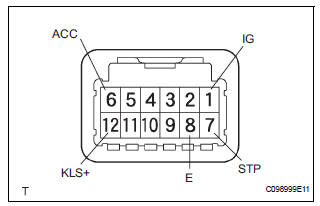

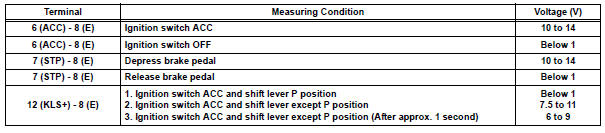

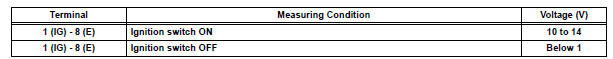

4. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY

(a) Measure the voltage according to the value(s) in the table below.

HINT: Do not disconnect the shift lock control unit assembly connector.

Voltage

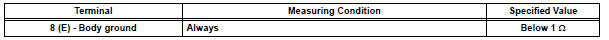

(b) Measure the resistance according to the value(s) in the table below.

HINT: Do not disconnect the shift lock control unit assembly connector.

If operation cannot be done as specified, replace the shift lever assembly.

Resistance

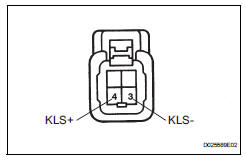

5. INSPECT KEY INTER LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Connect KLS+ (4) terminal to the batteries' positive (+) terminal and KLS (3) terminal to the battery negative (-) terminal, and apply about 12 V between KLS+ - KLS- terminals.

(c) Check that operation noise can be heard from the solenoid.

If the solenoid does not operate, replace the solenoid.

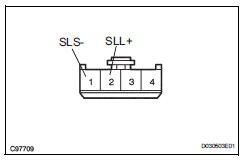

6. INSPECT SHIFT LOCK SOLENOID

(a) Disconnect the solenoid connector.

(b) Connect SSL+ (2) terminal to the batteries' positive (+) terminal, and SLS- (1) terminal to the battery negative (-) terminal, and apply about 12 V between SLL+-SLS- terminals.

(c) Check that operation noise can be heard from the solenoid.

If the solenoid does not operate, replace the solenoid.

Installation

Installation

1. Install transmission valve body assembly

(a) Install the shift solenoid valve SL1 to the valve body

assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(b) Install the shi ...

Shift lever

Shift lever

Components

...

Other materials:

Disassembly

1. INSPECT PACK CLEARANCE OF FORWARD

CLUTCH

HINT:

(See page AX-242)

2. REMOVE FORWARD MULTIPLE DISC CLUTCH DISC

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange, 5 discs and 5 plates from the

input shaft assembly.

3. REMOVE FORWARD CLUTCH RETURN SPRING

SUB-ASSEMB ...

Trailer Tongue Weight

A recommended tongue weight varies in accordance with the types

of trailers or towing as described below.

To ensure the recommended values shown below, the trailer must

be loaded by referring to the following instructions.

Tongue Weight

The gross trailer weight should be distribute ...

Adjustment

HINT:

On the RH side, use the same procedures as on the LH

side.

Since a centering bolt is used as door hinge mounting

bolts on the body side and the door side, the door cannot

be adjusted with them on. Substitute a bolt with a washer

for the centering bolt.

1. INSPECT BACK DOOR PAN ...