Toyota Sienna Service Manual: Knock sensor

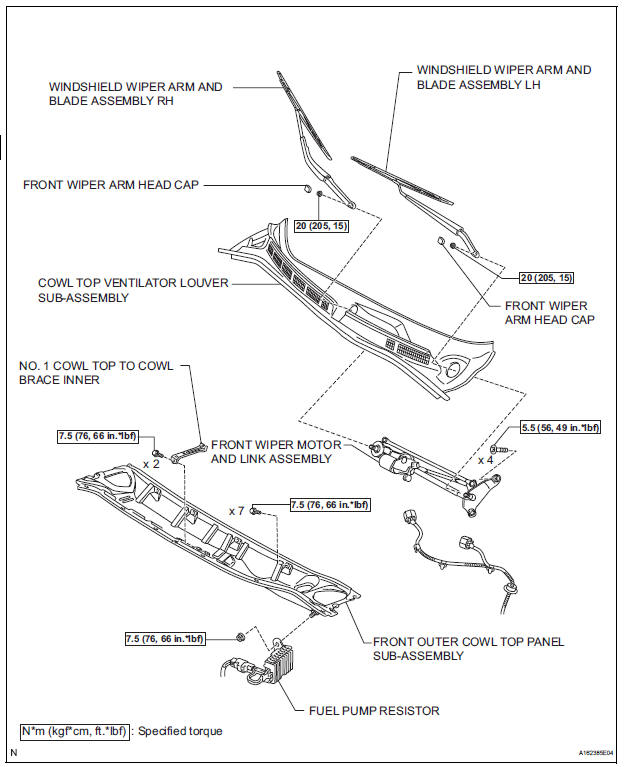

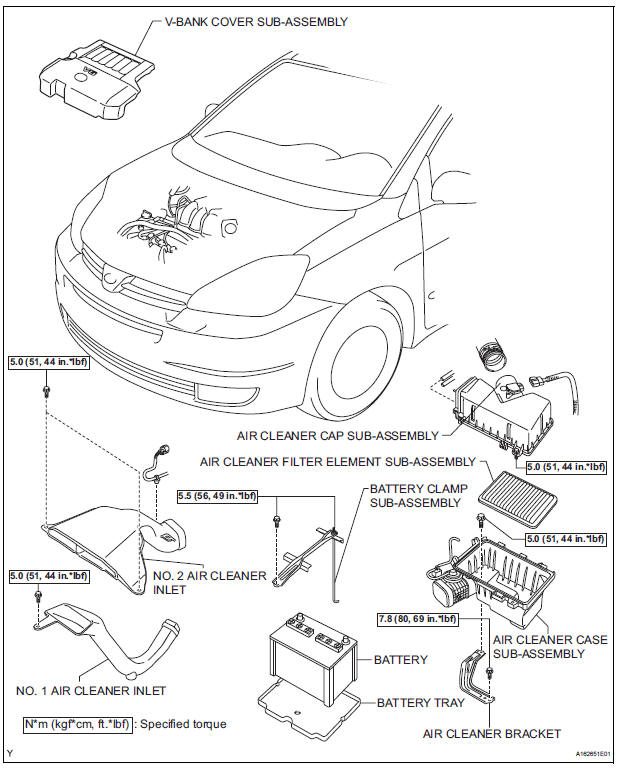

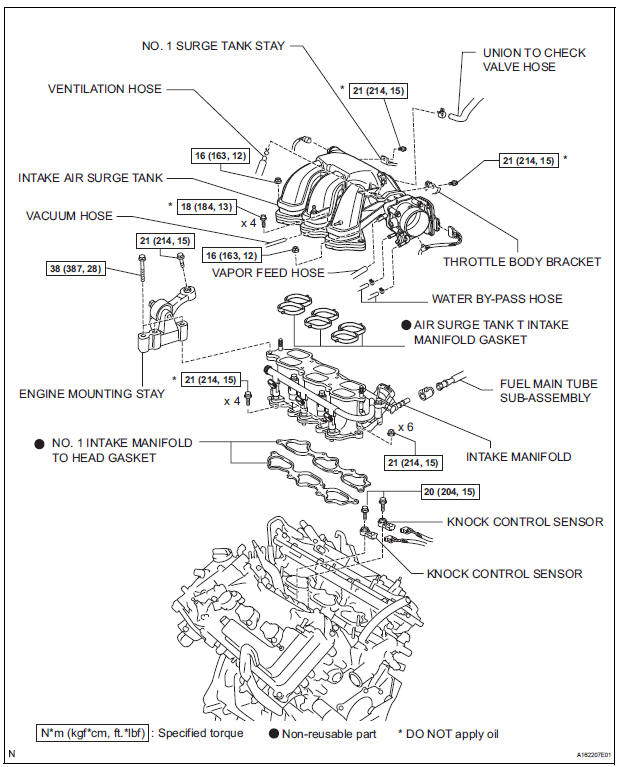

COMPONENTS

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page FU-13) 2. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28) 3. DRAIN ENGINE COOLANT (See page CO-6) 4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY HINT: (See page WW-4) 5. REMOVE FRONT OUTER COWL TOP PANEL SUBASSEMBLY (See page EM-27) 6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page ES-493) 7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See page EM-28) 8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

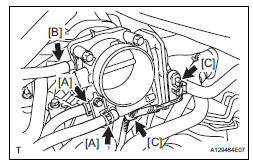

(a) Disconnect the 2 water by-pass hoses from the throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp [C].

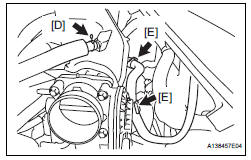

(d) Disconnect the ventilation hose [D].

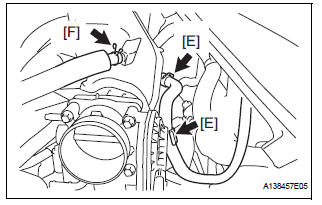

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

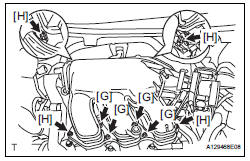

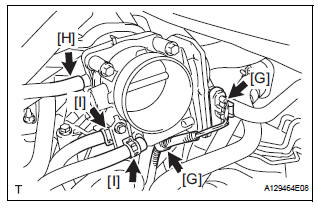

(g) Using a 5 mm socket hexagon wrench, remove the 4 bolts [G].

(h) Remove the 2 nuts, 2 bolts and intake air surge tank [H].

(i) Remove the gasket from the intake air surge tank [I].

9. REMOVE FUEL MAIN TUBE SUB-ASSEMBLY (See page EM-30) 10. REMOVE INTAKE MANIFOLD (See page EM-39)

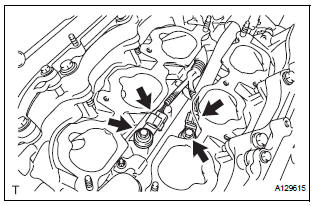

11. REMOVE KNOCK CONTROL SENSOR

(a) Disconnect the 2 knock sensor connectors.

(b) Remove the 2 bolts and then remove the 2 knock control sensors.

INSPECTION

1. KNOCK CONTROL SENSOR

(a) Using an ohmmeter, measure the resistance between the terminals.

Resistance: 120 to 280 kΩ at 20°C (68°F)

If the resistance is not specified, replace the knock control sensor.

INSTALLATION

1. INSTALL KNOCK CONTROL SENSOR

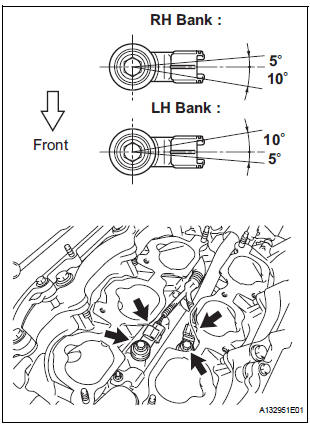

(a) Install the 2 knock control sensors with the 2 bolts as shown in the illustration.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf) (b) Connect the 2 knock control sensor connectors.

2. INSTALL INTAKE MANIFOLD (See page EM-49) 3. INSTALL FUEL MAIN TUBE SUB-ASSEMBLY (See page EM-56) 4. INSTALL INTAKE AIR SURGE TANK

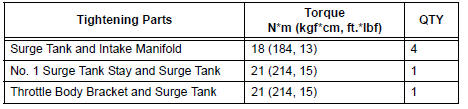

| NOTICE: DO NOT apply oil to the bolts listed below. |

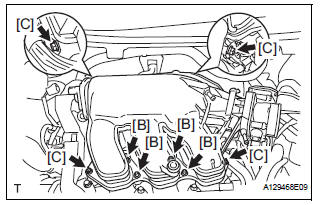

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4 bolts [B].

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf) (c) Install the intake air surge tank with the 2 nuts and 2 bolts [C].

Torque: Nut 16 N*m (163 kgf*cm, 12 ft.*lbf) Bolt 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector [D].

(e) Connect the union to check valve hose [E].

(f) Connect the ventilation hose No. 2 [F].

(g) Install the clamp and connect the throttle with motor body assembly connector [G].

(h) Connect the vapor feed hose [H].

(i) Connect the 2 water by-pass hoses to the throttle with motor body assembly [I].

5. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See page EM-59) 6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See page ES-496) 7. ADD ENGINE COOLANT (See page CO-7) 8. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1) 9. INSPECT FOR FUEL LEAK (See page FU-7) 10. INSTALL FRONT OUTER COWL TOP PANEL SUBASSEMBLY (See page EM-61) 11. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT: (See page WW-5)

12. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63)

Engine coolant temperature sensor

Engine coolant temperature sensor

COMPONENTS

REMOVAL

1. DRAIN ENGINE COOLANT (See page CO-6)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

4. REMOVE NO. 1 AIR CLEAN ...

Efi relay

Efi relay

INSPECTION

1. INSPECT EFI RELAY

(a) Using an ohmmeter, measure the resistance

according to the value(s) in the table below.

Standard resistance

If the result is not as specified, replace th ...

Other materials:

Installation

1. INSTALL LOWER BALL JOINT ASSEMBLY FRONT LH

(a) Install the lower ball joint assembly front LH and

tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf)

(b) Install a new cotter pin.

NOTICE:

If the holes for the cotter pin are not aligned,

tighten the nut further up to 60°.

2. INS ...

DTC check / clear

1. DTC CHECK (USING SST CHECK WIRE)

Check the DTCs (Present trouble code).

Turn the ignition switch ON, and wait for

approximately 60 seconds.

Using SST, connect terminals TC and CG of the

DLC3.

SST 09843-18040

NOTICE:

Connect the terminals to the correct

positi ...

Turn signal light switch

ON-VEHICLE INSPECTION

1. INSPECT TURN SIGNAL FLASHER CIRCUIT

Measure voltage between the terminals as shown in

the chart below.

Voltage

Connect the connector to turn the signal flasher and

turn the ignition switch ON, and inspect the wire

harness side connector from t ...